Standardized high-yield culture technique based on biological characteristics of asafetida mushroom

A kind of technology of asafoetida and biology, applied in the field of high-yield cultivation of edible fungi, can solve the problems of restricting the healthy development of the asafoetida industry, increasing the risk of the asafoetida mushroom, and high pollution rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1. Optimization of culture parameters of Pleurotus ferulai mycelium

[0017] The optimization of temperature and light parameters adopts the plate method. Use a Φ10mm sterile puncher to perforate and cultivate 7-day outer marginal mycelium on the plate medium. Use a sterile inoculating spatula to inoculate the colony on the Φ90mm plate medium. The center is placed in a light constant temperature incubator for cultivation. The experiment has 8 temperatures (15℃, 20℃, 25℃, 27℃, 29℃, 31℃, 33℃, 35℃) and light (dark light, 300lx, 400lx, 500lx, 600lx, 700lx, 800lx, 900lx) Treatment, each treatment is set 5 times to observe the influence of different temperature and light on the growth of Pleurotus ferulai.

[0018] The optimization of nutrient factors and pH value adopts the fermentation method, scrapes a certain amount of new-born mycelium from the outer margin that has been cultured on a plate medium for 7 days with a sterile inoculating hook, and inoculates it in a 250...

Embodiment 2

[0024] Example 2. Optimization of management parameters of Pleurotus ferulai

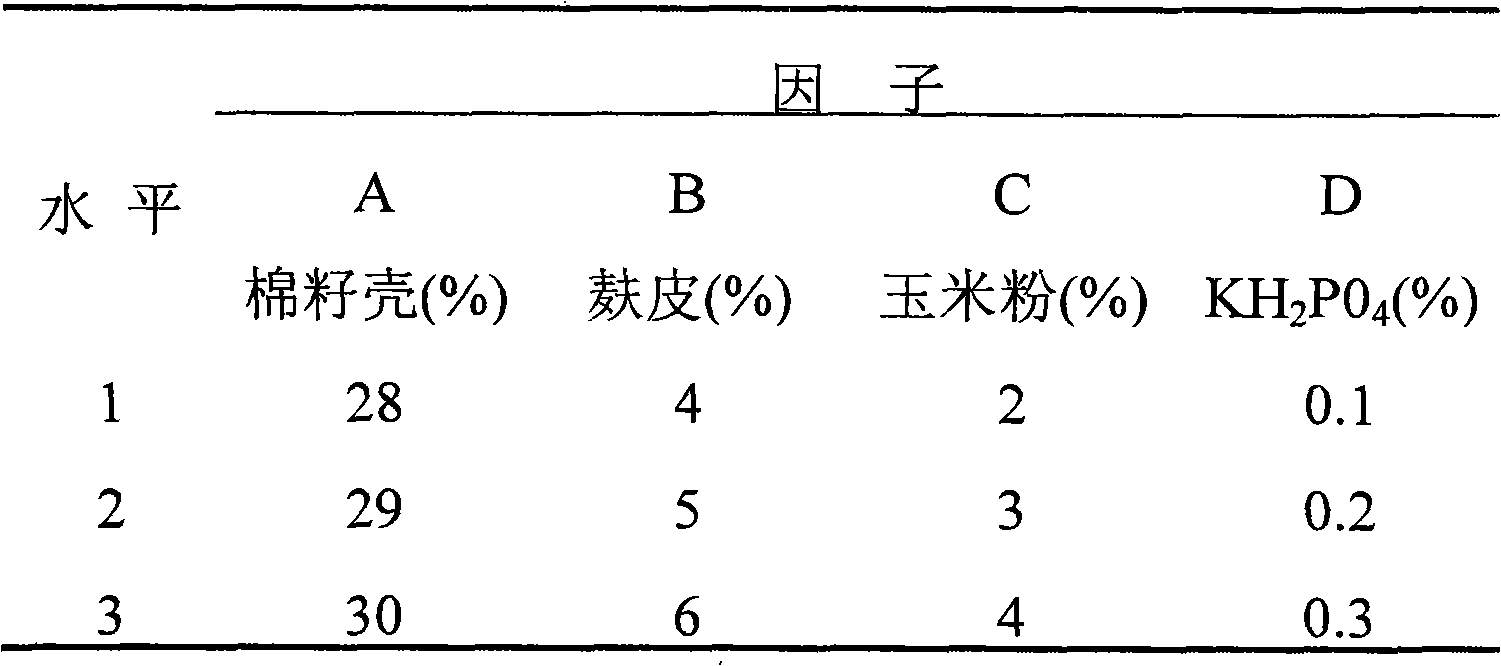

[0025] For cottonseed hulls, bran, corn flour, KH 2 PO 4 Four nutritional factors for L 9 (3) 4 (See Table 1) Orthogonal screening. Other nutritional factors: 1.0% white granulated sugar, 0.4% gypsum powder fixed, the rest is sterile water, pH value is 8-10 before sterilization. Inoculate the liquid strains in polypropylene bags (17cm×33cm) with different solid medium formulations and a filling amount of 1000g / bag according to 10% of the inoculation amount, sterilize at 121℃ for 3h, and place them in a light incubator after inoculation. Incubate at 25°C for 45 to 50 days. Each treatment was repeated 5 times to observe the effects of different combinations on the yield and quality of Pleurotus ferulai.

[0026] Table 1 Experimental factors and levels

[0027]

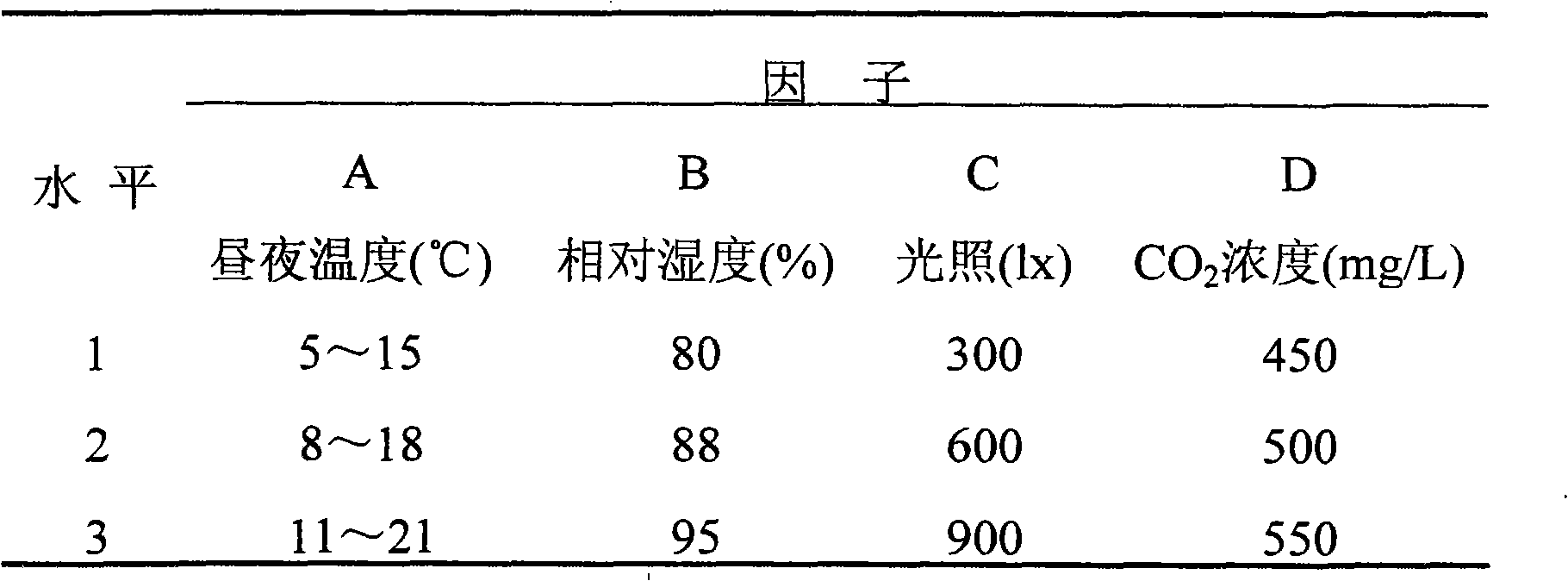

[0028] For day and night temperature, air relative humidity, light, CO 2 Concentration of four fruiting management parameters for L 9 (3) 4 (See ...

Embodiment 3

[0032] Example 3. Standardized cultivation techniques based on the biological characteristics of Pleurotus ferulai

[0033] Based on the biological characteristics of Pleurotus ostreatus, the standardized cultivation techniques for applying liquid seed production in the factory production of mushroom bags include inclined cultivation of mother seeds, seed bottle cultivation of original seeds, fermentation tank cultivation of cultivated species, and mushroom cultivation of mushroom bags. Several stages of fruiting culture and harvesting and processing. After culturing in a seed bottle and a fermenter, the fermentation broth is inoculated into the fruiting bag culture material and cultured at a constant temperature under the optimal culture parameters of the mycelium. After the mycelium is physiologically mature, the bacteria are scratched and the fruiting water is injected to carry out fruiting. Cultivation, post-harvest processing.

[0034] (1) Slope culture: scrape a small amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com