Structure formed by combining golf batting panel and head body and manufacturing method thereof

A molding structure and manufacturing method technology, which is applied to golf balls, golf clubs, casting molding equipment, etc., can solve the problems of reduced bonding strength, large stress concentration, and cost consumption, so as to prevent fire backlash and avoid fire backlash , The effect of reducing welding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

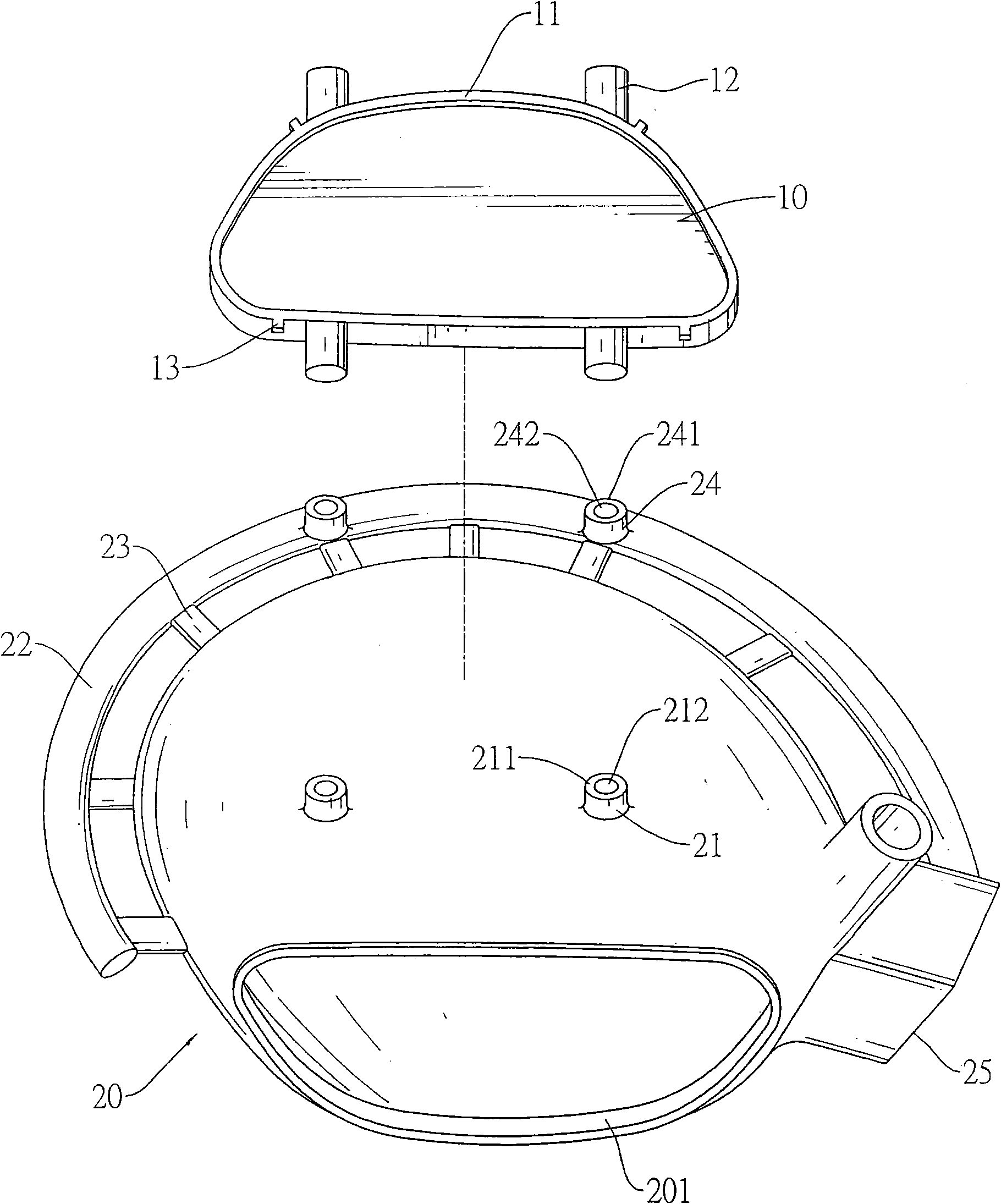

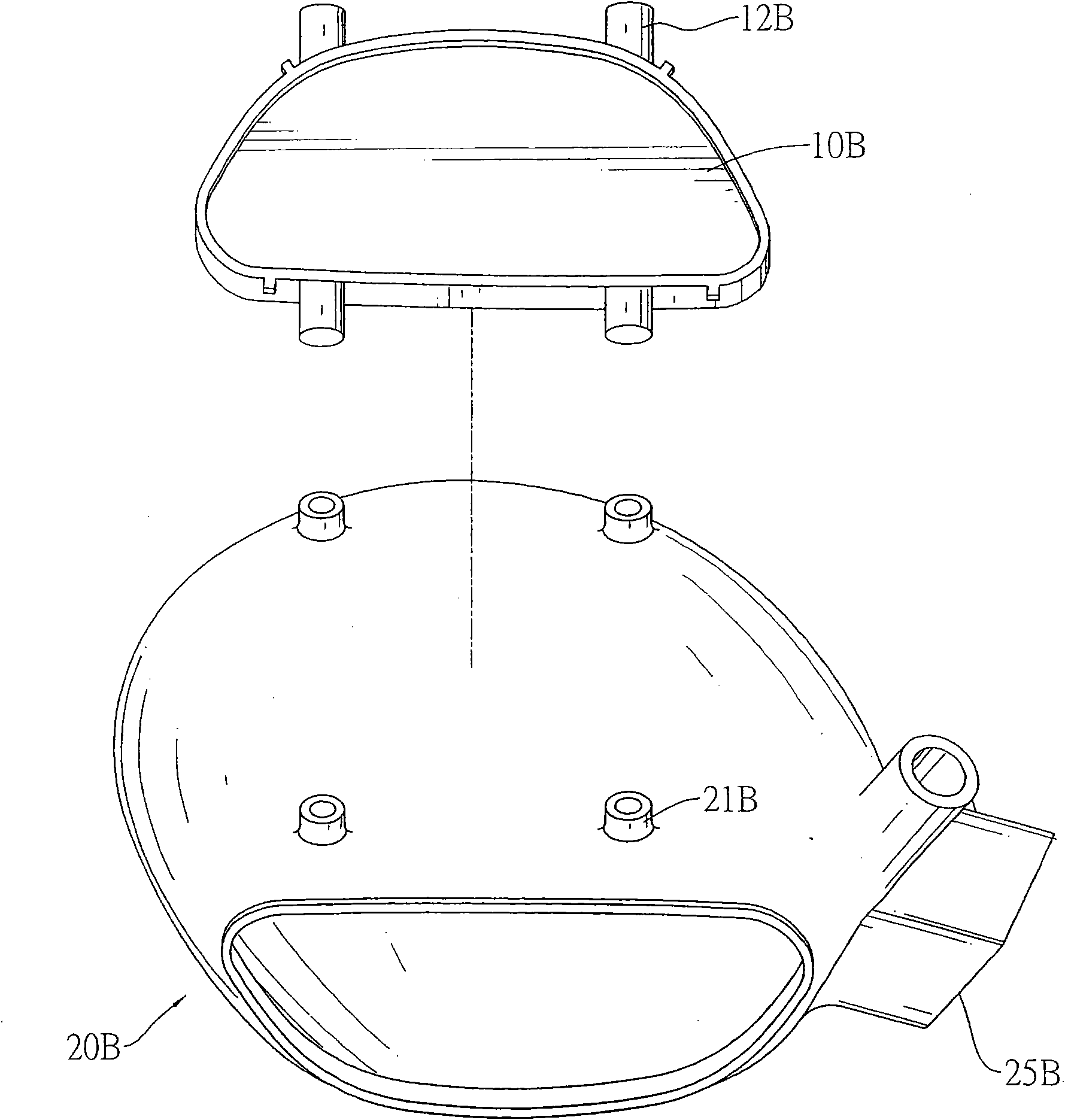

[0071] see figure 1 , 2 Shown is the structure of the golf ball hitting faceplate and the ball head body in conjunction with each other, which has a ball hitting faceplate wax mold 10 and a ball head body wax mold 20, the ball hitting faceplate wax mold 10 and the ball head body wax mold 20 is made of wax material, that is, the wax material is molded by mold respectively, and then through the precision casting process, the structure with both the hitting panel and the ball head body is cast and formed;

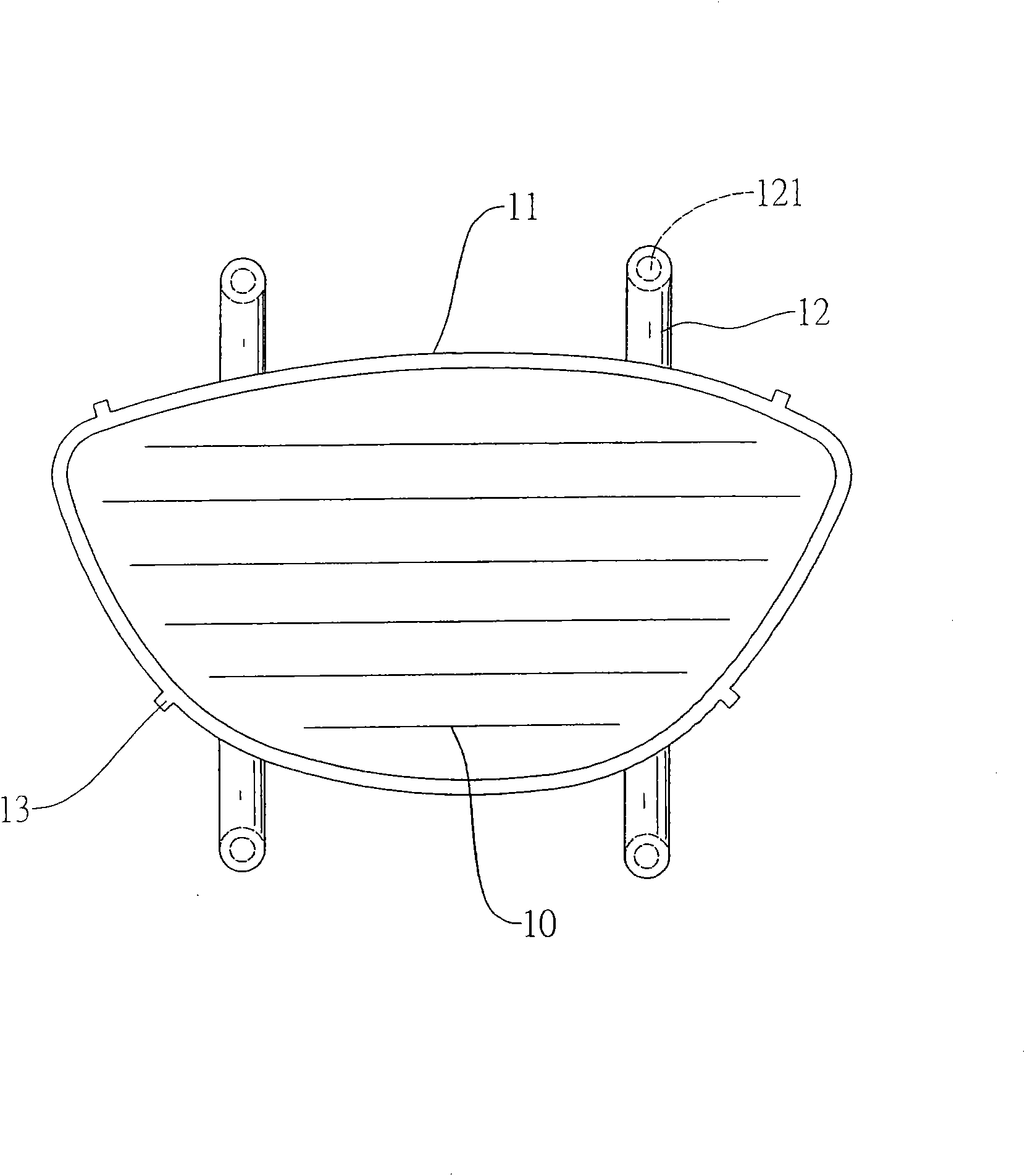

[0072] Cooperate with reference image 3 and 4A As shown, the aforementioned batting panel wax mold 10 made of wax material by the mold has a shape corresponding to the batting panel, and a protruding flange 11 is formed around the periphery of one side thereof, and another is formed on the periphery. A protruding auxiliary flow channel pillar 12, its preferred embodiment can be provided with four auxiliary flow channel pillars 12 as shown in the figure, each auxiliary flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com