Water-soluble thickener, preparation method thereof and application thereof in pesticide formulation

A technology of water-soluble thickener and preparation method, which is applied in the directions of dissolution, transportation and packaging, chemical instruments and methods, etc., can solve the problem that the adhesion effect of plant leaves has not attracted enough attention, and achieve the reduction of drug costs and reduction of Dosage, effect of improving efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In the round bottom flask, add 370 grams of dodecylamine, then add 400 milliliters of methanol, start stirring and drop into 294 grams of glutamic acid and 600 milliliters of water. Stir for 20 minutes, perform suction filtration, wash with methanol, and then vacuum-dry to obtain a white solid.

[0023] Get 332 grams of white solids and put them into a round-bottomed flask, and add 750 milliliters of xylene, stir evenly and add 0.03% concentrated sulfuric acid dropwise. Heated to reflux for 12 hours to remove the water formed therein. To the resulting liquid was added 100 ml of diethyl ether, and a solid precipitated out. After suction filtration, a light yellow solid was obtained.

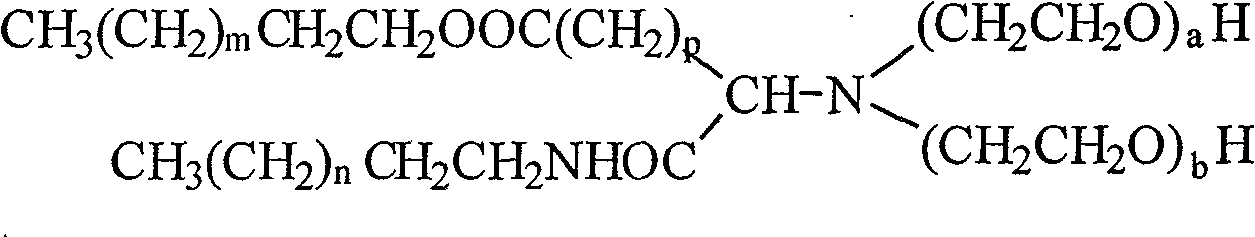

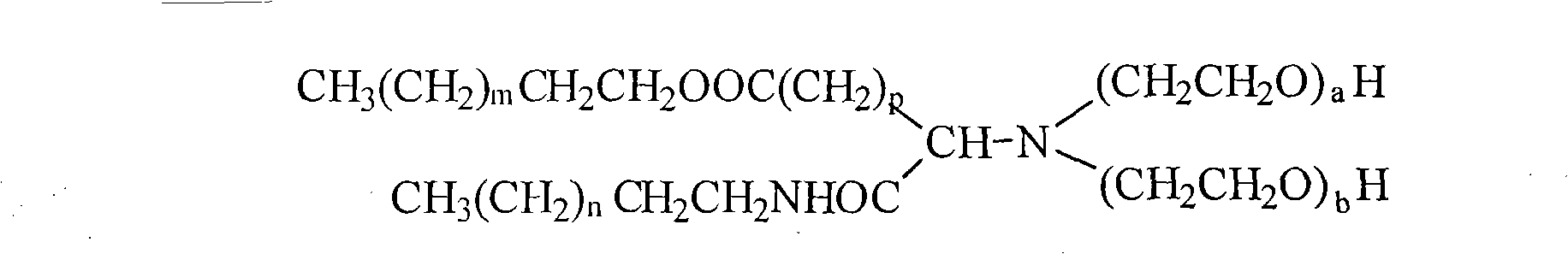

[0024] Get 125 grams of light yellow solid and put it into a round-bottomed flask, and add 250 milliliters of decanol, stir well, and then add 0.03% concentrated sulfuric acid dropwise. Heat to reflux for 12 hours. To the obtained liquid was added 300 ml of diethyl ether, and a solid wa...

Embodiment 2

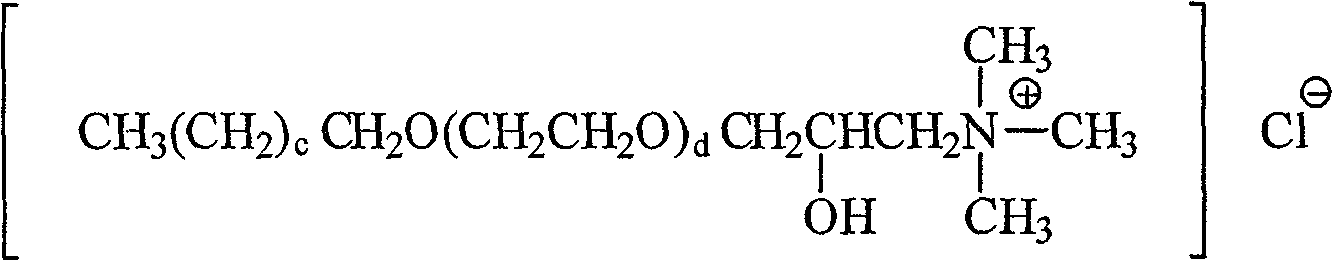

[0029] Add AEO-9, 145.5 grams, 50% NaOH aqueous solution 60g, phase transfer catalyst tetrabutylammonium bromide 12g in 500 milliliter there-necked flask, heat up while stirring, and add people's epichlorohydrin 46g simultaneously, heat up To 80±2°C, react under strong stirring for 1.5 hours, stop stirring and separate the lower layer. The upper layer evaporates unreacted epichlorohydrin through vacuum distillation,

[0030] In a 250 ml three-necked bottle, add 63.8 g of the fatty alcohol polyoxyethylene glycidyl ether obtained in the previous part, the mass fraction is 11.46 g of 33% trimethylamine aqueous solution, and 100 ml of absolute ethanol, and neutralize with concentrated HCl to Neutral, react at 70±2°C for 1 hour under stirring, distill ethanol and water to obtain quaternary ammonium salt surfactant.

[0031]

[0032] which can be used in C 10 ~C 18 Any kind of alcohol can replace dodecanol, and the amount of ethylene oxide added can be 3-10.

Embodiment 3

[0034] Preparation of water-soluble thickener:

[0035] Put 100 grams of any amino acid-based amphiphilic surfactant in Example 1 into a 1-kilogram reactor, then pump in 820 grams of water, start stirring, heat up to 50-55 degrees, stir for 30 minutes until the solids are completely dissolved, and then Add 80 grams of the quaternary ammonium salt surfactant in Example 2, stir for 30 minutes, and the obtained colorless viscous liquid is the water-soluble thickener of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com