Biodegradable gasified antirust pearl cotton and manufacturing method thereof

A gasification anti-rust and biodegradable technology, applied in the direction of sustainable manufacturing/processing, bio-packaging, climate sustainability, etc., can solve problems such as burning and the environment, and achieve increased biodegradability, advanced technology, and reduced operations Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

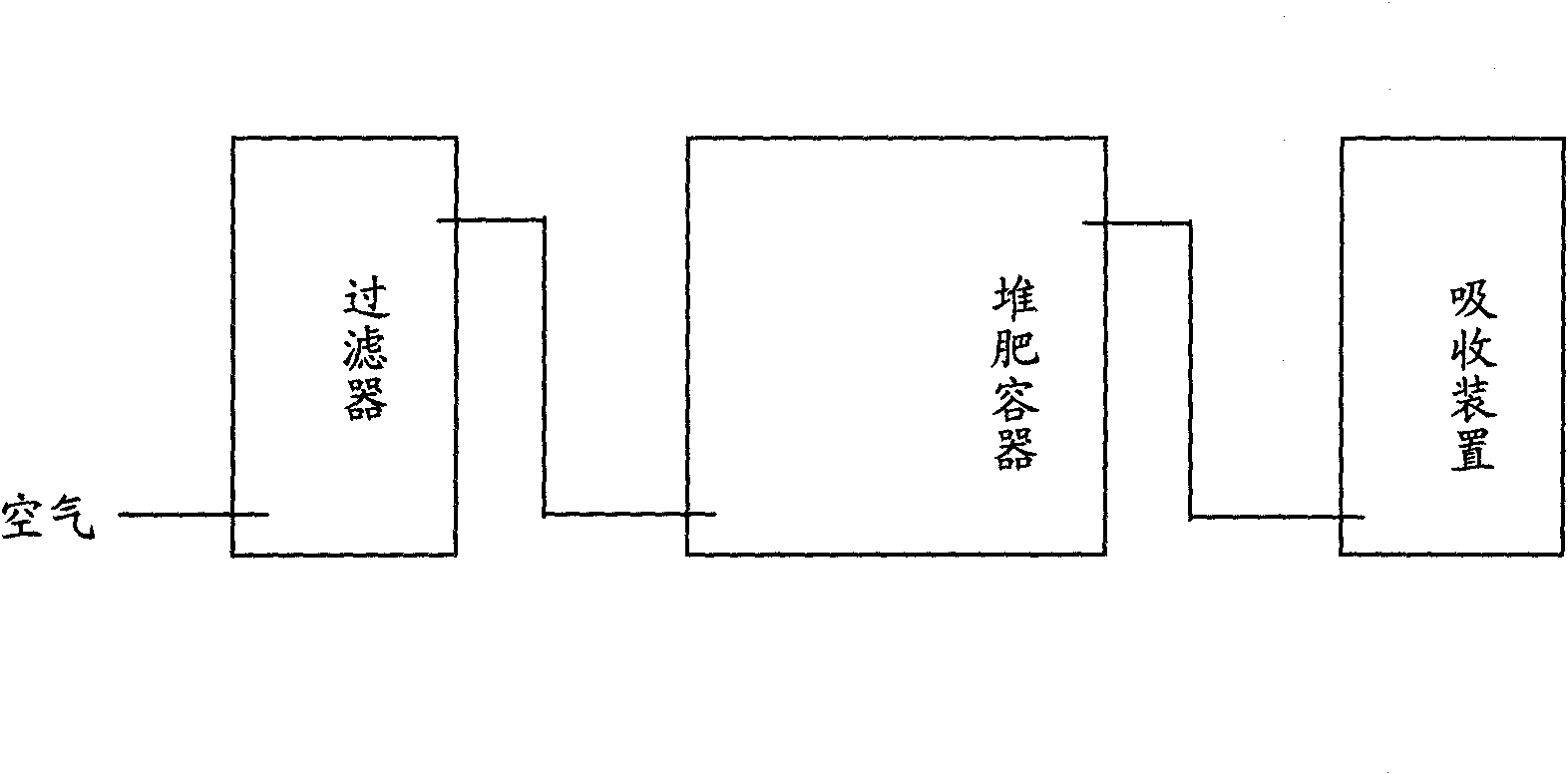

Method used

Image

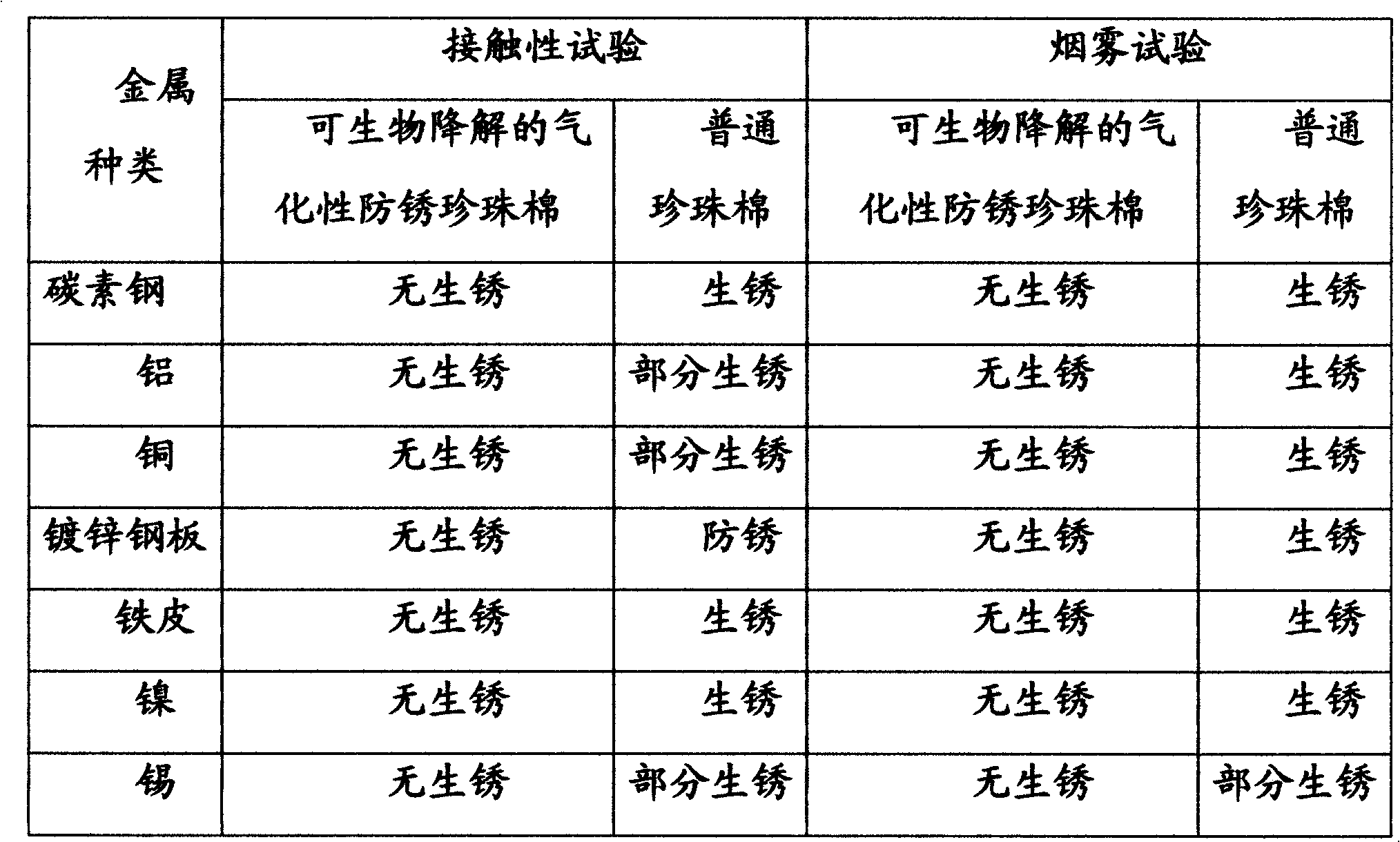

Examples

Embodiment

[0072] The manufacture method of biodegradable gasification antirust pearl cotton disclosed by the present invention is produced according to the following steps:

[0073] a, according to the steps of configuring raw materials in parts by weight:

[0074] Sodium benzoate (sodium benzoate) 10 parts,

[0075] Dextrin (dextrin) 4 parts,

[0076] 6 parts of benzotriazole,

[0077] Sodium molybdate (sodium molibdate) 6 parts,

[0078] B, the step of mixing materials: put sodium benzoate, dextrin, phenylacryltriazole, sodium molybdate into the blender respectively for mixing; then put the mixed material into the pulverizer and pulverize it into a size of 250-350 mesh;

[0079] c. Steps for configuring the dispersant according to the ratio in parts by weight:

[0080] Hydroxyethyl cellulose (Hydroxy ethyl cellulose) 5 parts,

[0081] Zinc stearate (zinc stearate) 7 parts,

[0082] Polyethylene wax (PE wax) 7 parts,

[0083] d, the step of secondary mixing: put hydroxyethyl cel...

PUM

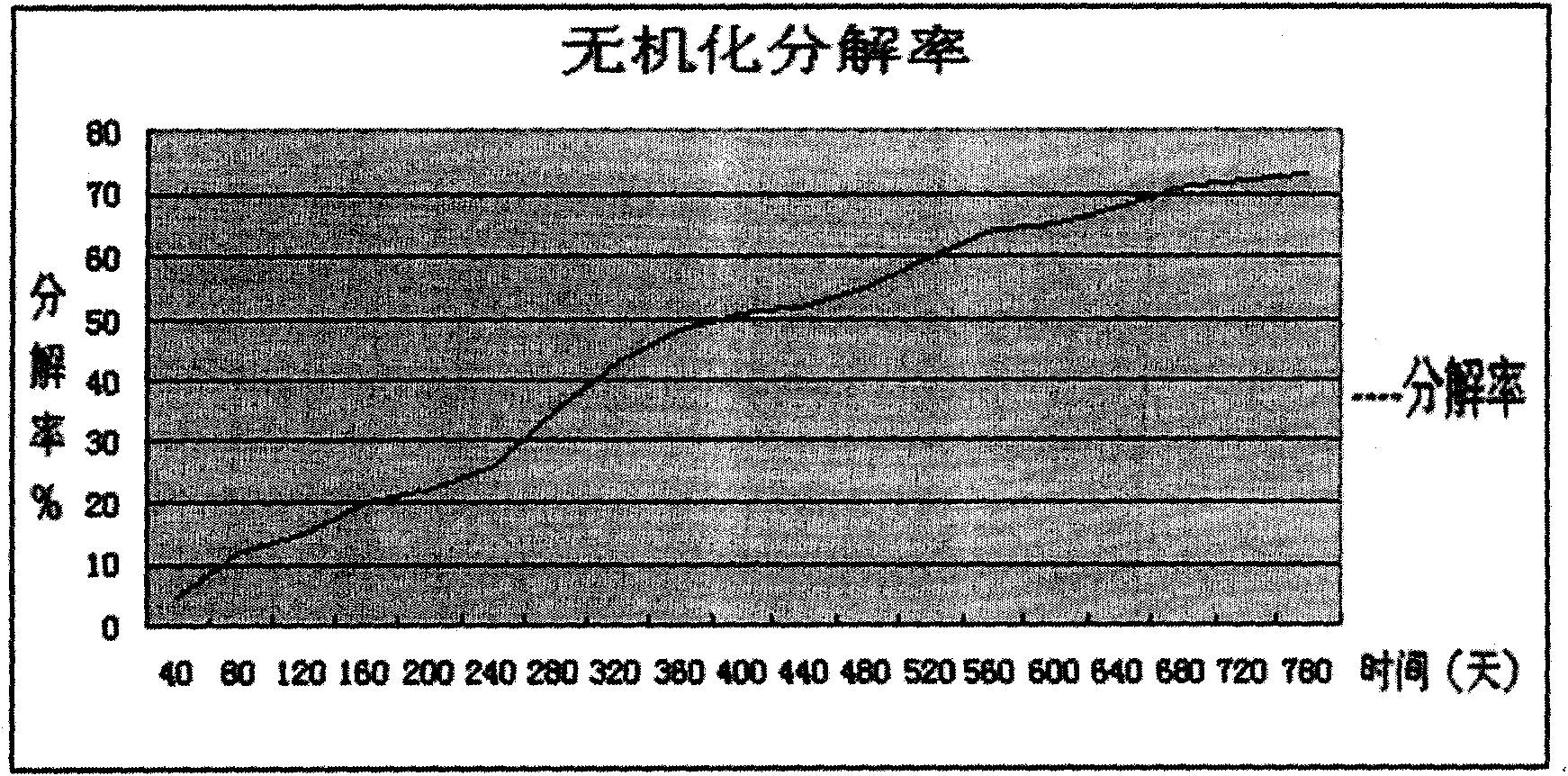

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com