Atomic absorption spectrometry of content of Fe and Zn impurities in yellow phosphorus

A technology of impurity content and determination method, applied in the direction of color/spectral characteristic measurement, test sample preparation, etc., can solve the problem of inability to directly measure Fe and Zn impurities in high-purity yellow phosphorus, and achieve precision and detection limit Satisfy, eliminate inhibitory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

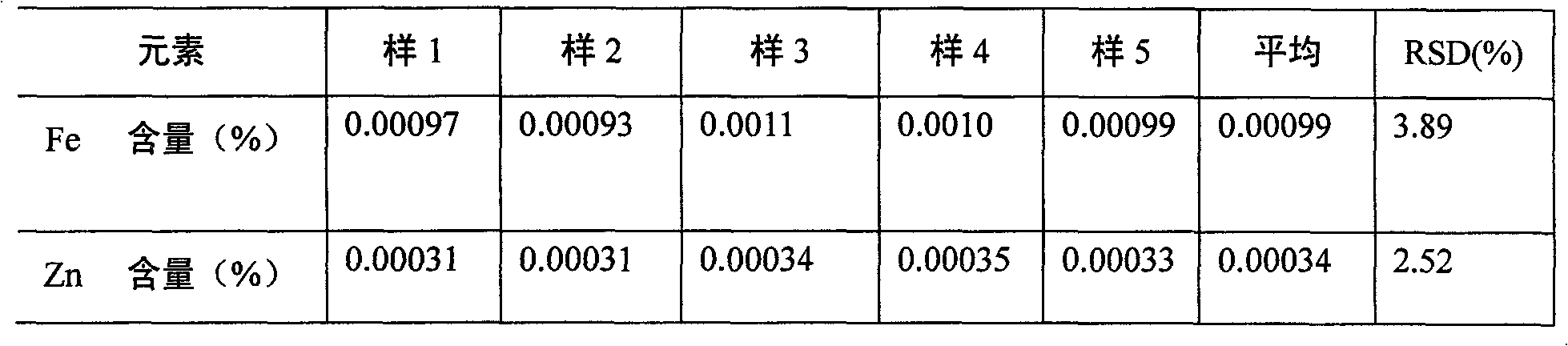

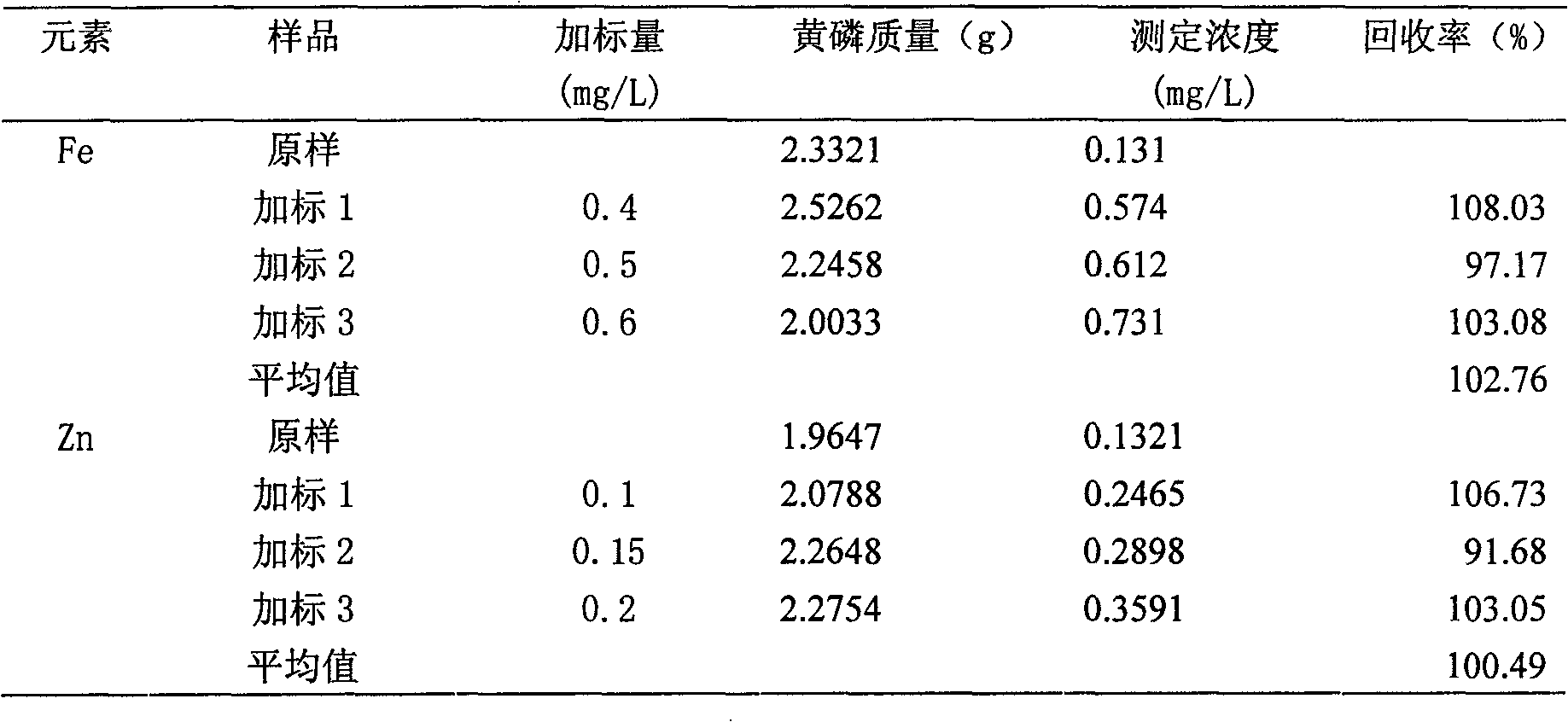

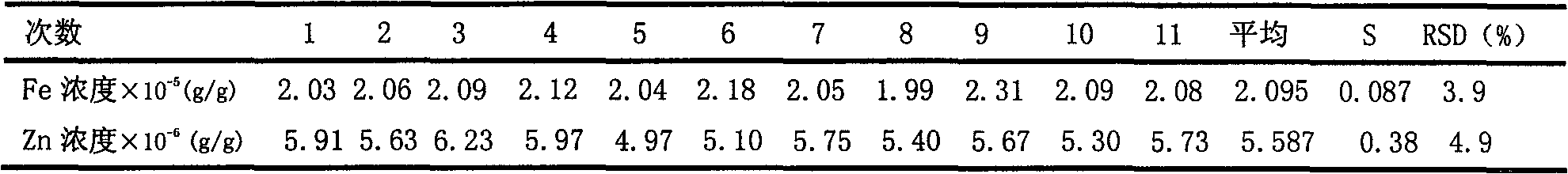

[0023] 1. Determination of iron and zinc impurities

[0024] (1) the yellow phosphorus sample of iron-zinc impurity content to be measured is digested with the nitric acid of volume concentration 70%, and the sample solution that the phosphoric acid concentration is obtained is 0.6mol / l;

[0025] (2) Phosphoric acid in the sample solution prepared in step (1) is extracted and separated with tributyl phosphate, the volume ratio of the sample solution and tributyl phosphate is controlled to be 1: 1, and the extraction process time is about 10min, so that the sample solution About 80% (mol concentration) of the phosphoric acid in the solution is extracted, the organic phase is discarded, the water phase is retained, and the water phase is left to stand for about 30 minutes. The water phase after standing is the sample water used to measure zinc and iron impurities in yellow phosphorus phase solution, the treated sample water phase solution was constant volume, and set aside;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com