A kind of determination and evaluation method of surfactant emulsifying performance

A surfactant and emulsifying performance technology, applied in the direction of scattering characteristic measurement, measuring device, transmittance measurement, etc., can solve the blurring of the interface between the oil phase and the emulsion phase, the difficulty of accurately measuring the amount of emulsified oil, and the inability to reflect the aggregation stability of the emulsion, etc. problems, to achieve the effects of avoiding human error interference, good operability and practicability, and enriching measurement and evaluation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The mensuration and the evaluation of embodiment 1 surfactant emulsifying performance

[0041] Proceed as follows:

[0042] (1) Pour 5mL of simulated oil and 5mL of 0.4% surfactant solution to be tested (the main component is fatty alcohol polyoxyethylene ether sodium sulfate) into the sample cell respectively, and let it stand at the experimental temperature (70°C) for 0.5h , placed in a rotary incubator, rotated and mixed at a rate of 80rad / min for 1h, and fully mixed the simulated oil and the surfactant solution.

[0043] The simulated oil used in this example is dehydrated crude oil from Shengli Oilfield, with 6% saturated content, 72% aromatic content, 14% colloid and 8% asphaltenes.

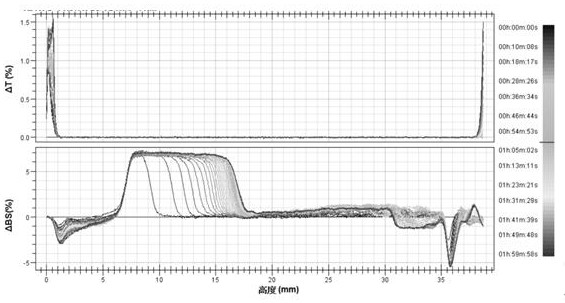

[0044] (2) Use the multiple light scattering instrument to measure the change law of the backscattered light intensity with the measurement height and time at a scanning frequency of 1 time / 2min, and obtain the reference spectrum of the backscattered light and the reference spectrum...

Embodiment 2

[0054] Embodiment 2 Surfactant product emulsifying performance quality detection

[0055] Proceed as follows:

[0056] Sampling of the first batch of samples

[0057] (1) Pour 5mL of simulated oil and 5mL of 0.4% surfactant solution (alkyl alcohol polyoxyethylene ether carboxylate) into the sample cell respectively, and after standing for 0.5h at the experimental temperature of 70°C, place Rotate the incubator, rotate and mix at a rate of 80rad / min for 1h, and fully mix the simulated oil and surfactant solution.

[0058] (2) Use the multiple light scattering instrument to measure the change law of the backscattered light intensity with the measurement height and time at a scanning frequency of 1 time / 2min, and obtain the reference spectrum of the backscattered light and the reference spectrum of the transmitted light, as shown in Figure 4 shown.

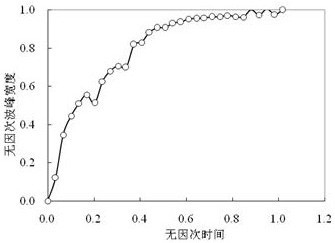

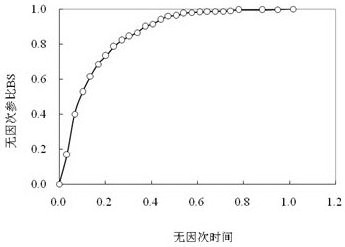

[0059] (3) Determine the evaluation reference time point T according to the experimental needs and the rate of change of the em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com