Magnetic field generator insert cartridge for applying magnetic field in molding process of polymer materials

A technology of polymer materials and magnetic field generators, applied in the direction of magnets, magnetic objects, ohmic resistance heating, etc., can solve the problem that the temperature cannot be accurately controlled, and achieve the effect that is conducive to the strength of the magnetic field and the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

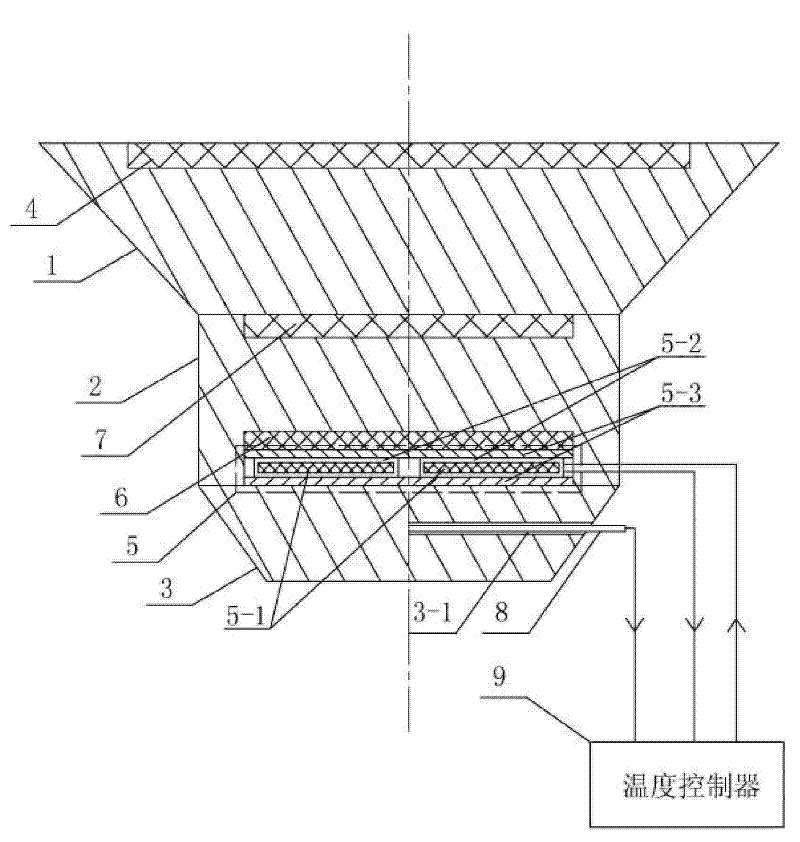

[0011] Specific implementation mode one: the following combination figure 1 Describe this embodiment, this embodiment comprises the first pole head 1, the second pole head 2 and the third pole head 3, and it also includes the first heat insulation layer 4, heating sheet 5, asbestos layer 6, thermocouple 8 and temperature Controller 9, the heating plate 5 is composed of a mica plate 5-1, a resistance wire 5-2 and two insulating plates 5-3, the resistance wire 5-2 is spirally wound on the mica plate 5-1, and the mica plate 5- 1. It is clamped and fixed by two insulating plates 5-3;

[0012] The first pole head 1 and the third pole head 3 are respectively a circular frustum, the second pole head 2 is a cylinder, the large end of the first pole head 1 has a first circular groove, and the first circular groove is provided with the first circular groove. A heat insulation layer 4, the small end face of the first pole head 1 overlaps and is fixedly connected with the upper end face ...

specific Embodiment approach 2

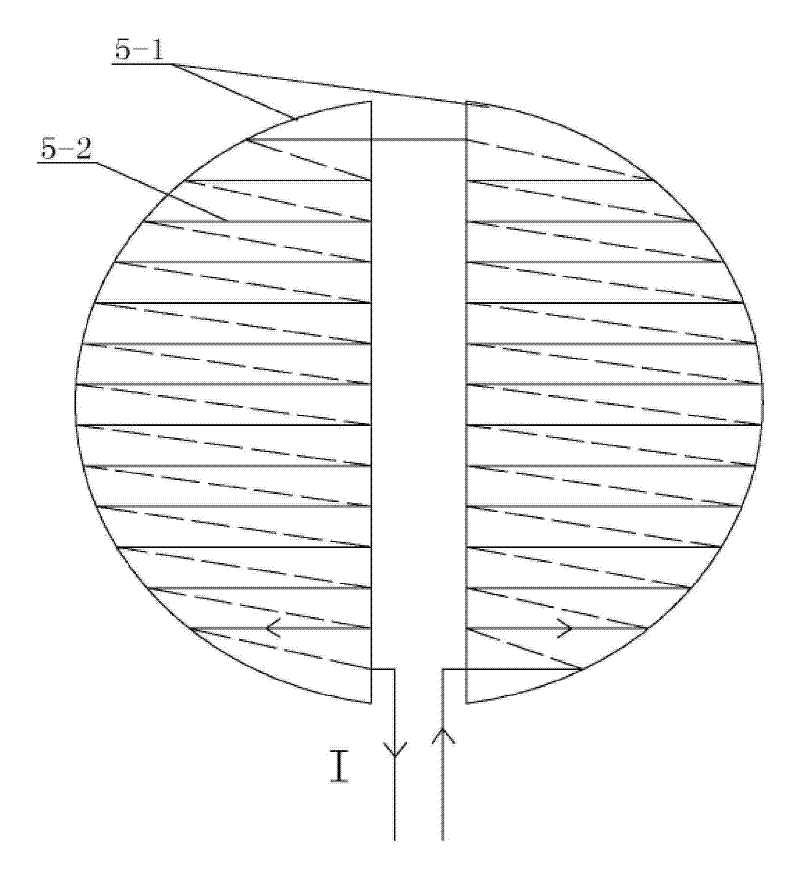

[0016] Specific implementation mode two: the following combination figure 2 Describe this embodiment, the difference between this embodiment and Embodiment 1 is that the mica plate 5-1 is two semicircular mica plates that are arranged axisymmetrically to each other, and the resistance wire 5-2 follows the same turn along the length direction. The distance is spirally wound on each semicircular mica plate in turn. Other components and connections are the same as those in Embodiment 1.

[0017] Since the turn pitch of the resistance wire wound on each semicircular mica board is the same, the heat energy converted from electric energy is evenly distributed. even heating. The heating power of the heating sheet 5 can be adjusted by changing the length of the heating resistance wire 5-2 according to actual needs.

specific Embodiment approach 3

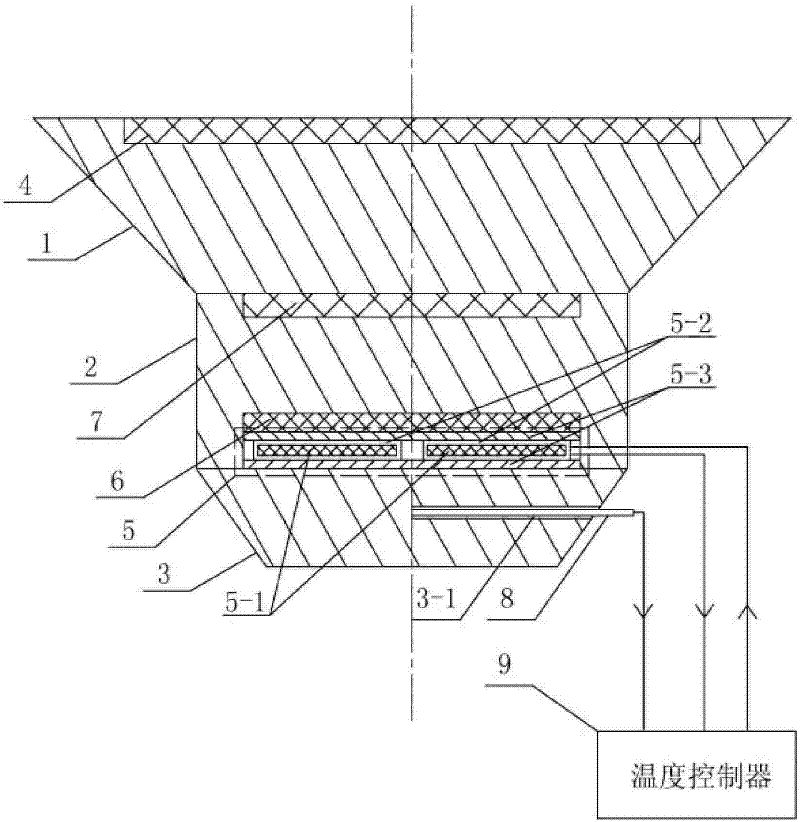

[0018] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the winding direction of the resistance wire 5-2 on the two semicircular mica boards is opposite. Other components and connections are the same as those in Embodiment 2.

[0019] Since the turn pitch of the resistance wire wound on the mica board is the same, and the winding direction is opposite, when the resistance wire is energized, the magnetic field generated by the current is opposite in direction and approximately equal in size, and the two magnetic fields in opposite directions weaken each other, thereby reducing The effect of the additional magnetic field generated by electric heating on the working magnetic field between the heads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com