Liquid crystal aligning agent and liquid crystal display element

A technology of liquid crystal display element and liquid crystal alignment agent, which is applied in the directions of instruments, optics, nonlinear optics, etc., can solve the problems of insufficient storage stability and insufficient liquid crystal alignment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0089] Liquid crystal orientation

[0090] The liquid crystal display elements produced in Examples and Comparative Examples were observed with a polarizing microscope to see if abnormal regions appeared when the voltage was turned on / off (applied / released), and it was judged as "good" when no abnormal regions appeared. Table 1 put together the result of evaluating liquid-crystal orientation about each aligning agent.

[0091] voltage retention

[0092] A voltage of 5 V was applied to the liquid crystal display element for 60 microseconds in a span of 167 microseconds, and then the voltage retention rate after 167 microseconds from the release of the applied voltage was measured. As the measuring device, VHR-1 manufactured by Toyo Technica Co., Ltd. was used. A case where the voltage retention rate was 90% or more was judged to be good, and a case other than that was judged to be bad. Table 1 summarizes the results of evaluating the voltage retention ratio for each align...

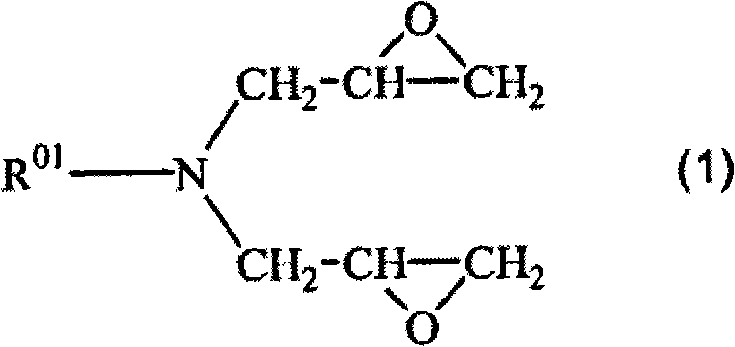

Synthetic example 1

[0097] In a 200ml three-neck flask equipped with a Dimro reflux condenser, mix 12.52ml (0.16mol) of epichlorohydrin, 18ml of ethanol, and 1.8ml of pure water, and heat up to 50°C while stirring. 4.53 g (0.04 mol) of aminomethylcyclohexane was dropped into the solution, and the temperature of the reaction solution was raised during the drop, and the reaction temperature was controlled between 48°C and 53°C. Then, it was heated and stirred within the temperature range for 3 hours, then the reaction temperature was controlled at 30° C., 8 g of 50% NaOH aqueous solution was added dropwise over 45 minutes, and it was further heated and stirred at this temperature for 3 hours. The precipitated salt was removed by filtration, the filtrate was transferred to an eggplant-shaped beaker, and ethanol was removed by an evaporator. 30 ml of toluene was added to the residue, washed four times with 15 ml of pure aqueous solution, and once with 15 ml of saturated saline aqueous solution. Afte...

Synthetic example 2

[0100] In a 200ml three-neck flask equipped with a Dimro reflux condenser, mix 12.52ml (0.16mol) of epichlorohydrin, 18ml of ethanol, and 1.8ml of pure water, and heat up to 50°C while stirring. 4.29 g (0.04 mol) of benzylamine was dropped into the solution, and the temperature of the reaction solution was raised during the drop, and the reaction temperature was controlled between 48°C and 53°C. Then, it was heated and stirred within the temperature range for 3 hours, then the reaction temperature was controlled at 30° C., 8 g of 50% NaOH aqueous solution was added dropwise over 45 minutes, and it was further heated and stirred at this temperature for 3 hours. The precipitated salt was removed by filtration, the filtrate was transferred to an eggplant-shaped beaker, and ethanol was removed by an evaporator. 30 ml of toluene was added to the residue, washed four times with 15 ml of pure aqueous solution, and once with 15 ml of saturated saline aqueous solution. After drying th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com