Method for preparing chlorinated polyvinyl chloride by low-temperature plasma circulating fluidize bed and device

A technology of chlorinated polyvinyl chloride and low-temperature plasma, which is applied in the field of plasma circulating fluidized bed preparation of chlorinated polyvinyl chloride, can solve serious pollution problems, achieve uniform particle flow, easy control of process parameters, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

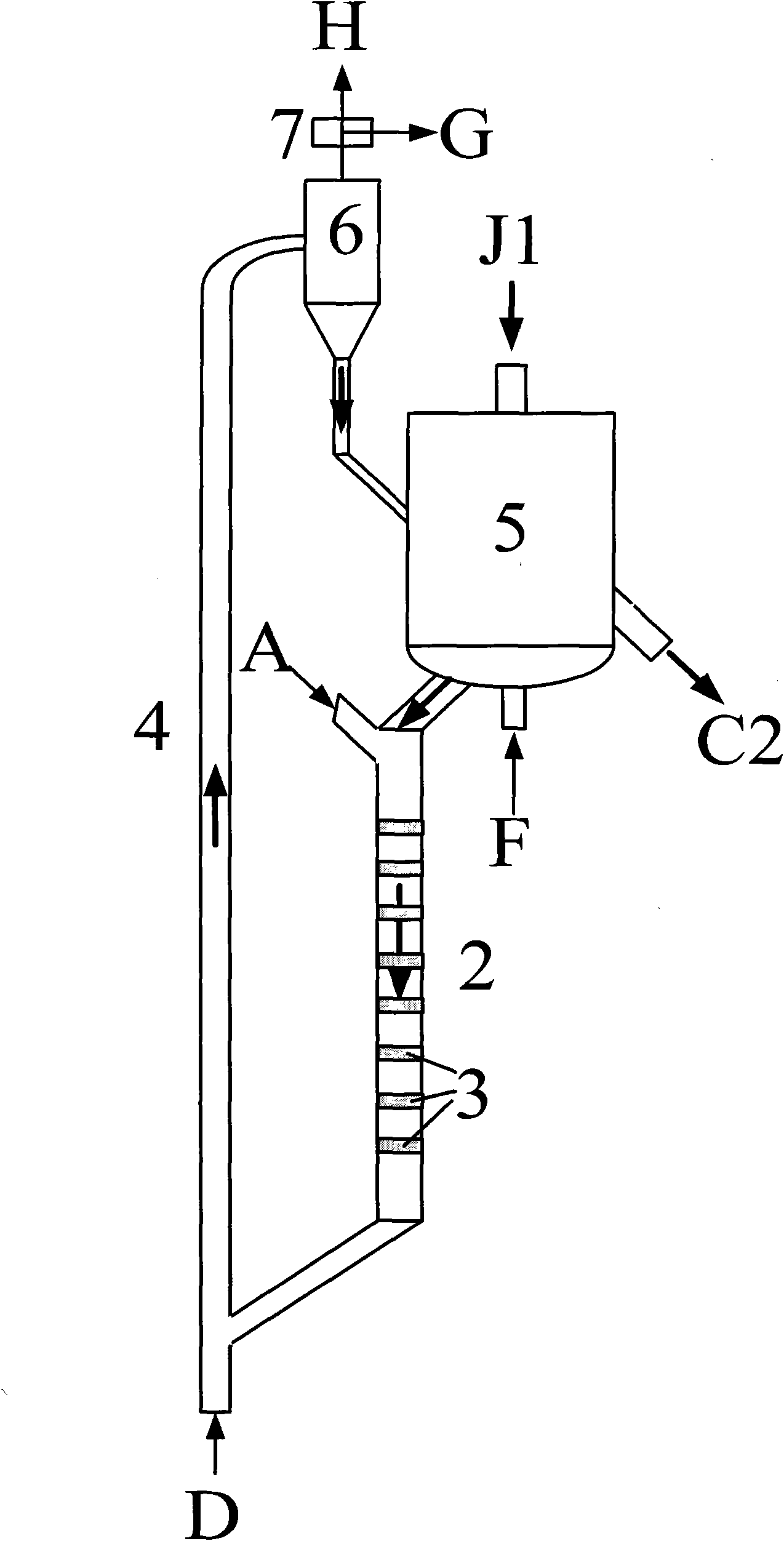

[0059] like figure 1 In the reaction device shown, polyvinyl chloride raw material particles with a particle size distribution of 15 μm to 200 μm are used, pure chlorine gas is fed, the operating pressure of the down-bed reactor is 1 atm, and the dielectric barrier discharge is adopted to realize polymerization in the down-bed. The surface chlorination of vinyl chloride particles increases the chlorine content of polyvinyl chloride from 57% to 61%. The particles continue to enter the riser reactor, go up under the drive of inert gas, enter the gas-solid separator, and the solid particles enter the The temperature is distributed in the turbulent bed at 80°C-90°C to realize the migration and homogenization of surface chlorine to the inside, and continue to enter the descending bed to circulate and carry out the chlorine addition migration reaction, and the hydrogen chloride gas in the mixed gas after passing through the gas-solid separator It is separated by the gas separator, a...

Embodiment 2

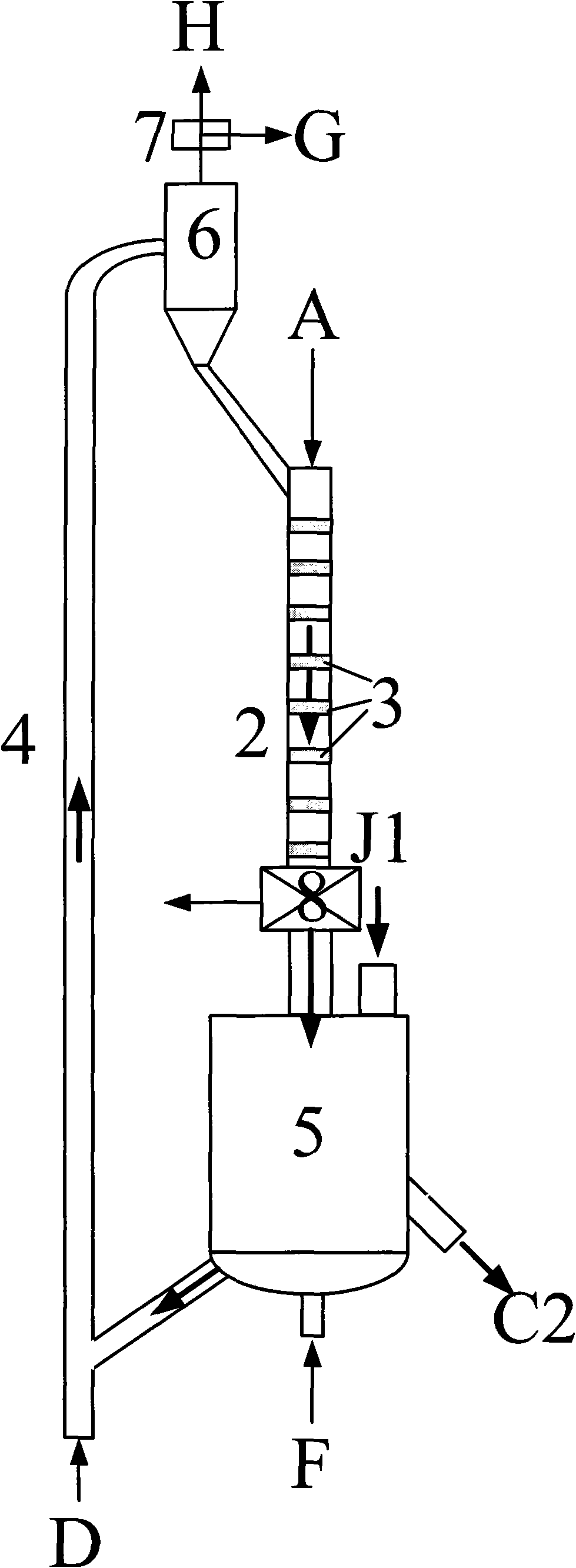

[0061] like figure 2 In the reaction device shown, polyvinyl chloride raw material particles with a particle size distribution of 150 μm to 250 μm are used, pure chlorine gas is fed, the operating pressure of the down-bed reactor is 1 atm, and the dielectric barrier discharge is adopted to realize polymerization in the down-bed. The surface chlorination of vinyl chloride particles increases the chlorine content of polyvinyl chloride from 57% to 60%. After the particles pass through the gas-solid separator, they enter the turbulent bed with a temperature distribution of 90°C-100°C to achieve the chlorine on the surface. The internal migration and homogenization continue to enter the riser reactor under the action of supplementary air. There is still a dielectric barrier discharge device in the riser reactor, and the surface chlorination reaction of polyvinyl chloride continues, and the chlorine content increases to 61.5%. After entering the gas-solid separator, the separated s...

Embodiment 3

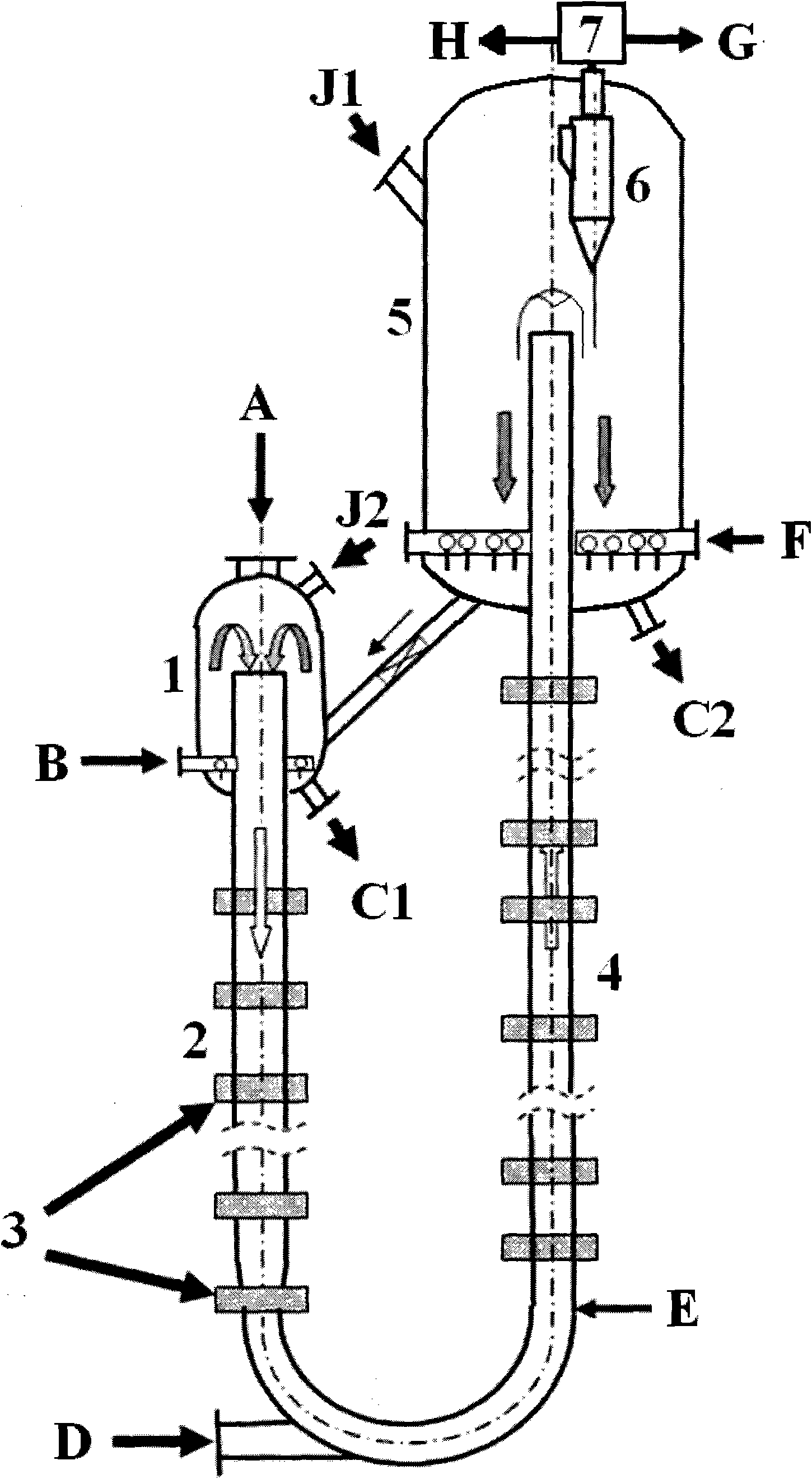

[0063] like image 3 In the reaction device shown, polyvinyl chloride raw material particles with a particle size distribution of 80 μm to 120 μm are used, inert carrier gas and chlorine gas are fed at a ratio of 2:1, the operating pressure of the down-bed reactor is 1 atm, and a dielectric barrier is used. In the form of discharge, the surface chlorination of polyvinyl chloride particles is realized in the down-going bed, so that the chlorine content of polyvinyl chloride increases from 57% to 59%, and the particles continue to enter the riser reactor and go up under the drive of inert gas. There is still a dielectric barrier discharge device in the riser reactor, and the surface chlorination reaction of polyvinyl chloride continues, and the chlorine content is increased to 60%, and then the particles enter the turbulent bed with a temperature distribution of 80°C-105°C to realize surface chlorine chlorination. Internal migration and homogenization, continue to separate the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com