Preparation method of catalyst for cathode of direct methanol fuel cell

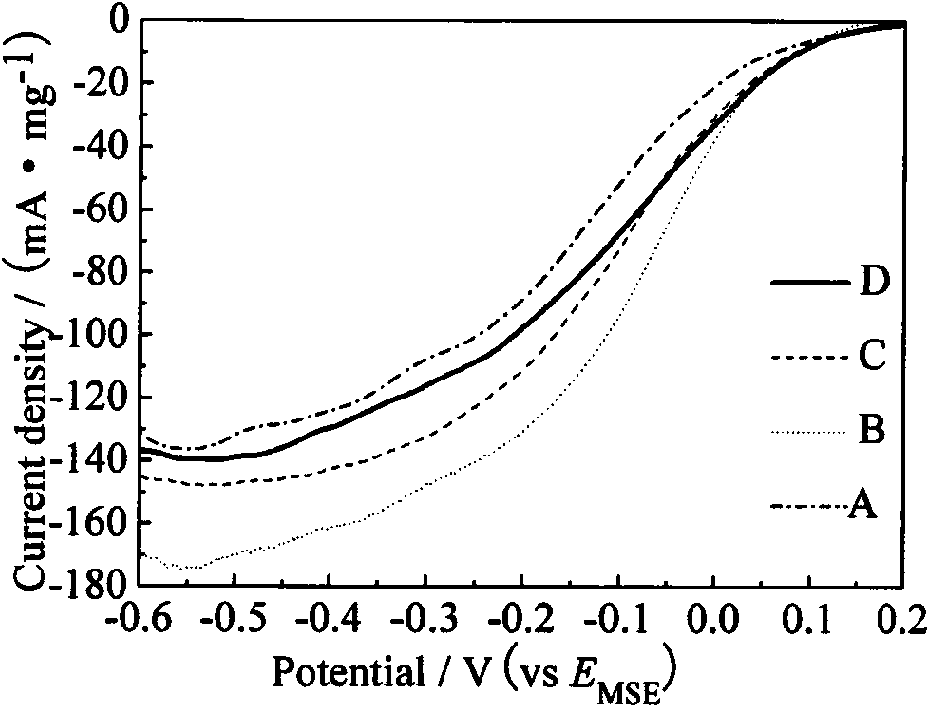

A methanol fuel cell and catalyst technology, applied in battery electrodes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low battery output power, low cathode activity, poor selectivity, etc., and achieve good stability and cost Effect of low and high methanol resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Add 40ml of ethylene glycol into the reactor, pass nitrogen for 30min, then add 0.2mmol CoCl 2 ·6H 2 O. 200mg polyvinylpyrrolidone (PVP), stirring at 85°C and continuing to feed nitrogen, then adding a concentration of 0.3mol L -1 , with 1mol L -1 NaOH aqueous solution adjusts 0.2ml of hydrazine hydrate solution with a pH value of 13, and the dropping rate is 40 drops·min -1 , continue stirring and reacting for 35min to obtain Co nano catalyst sol, and then filter to obtain Co nanoparticles;

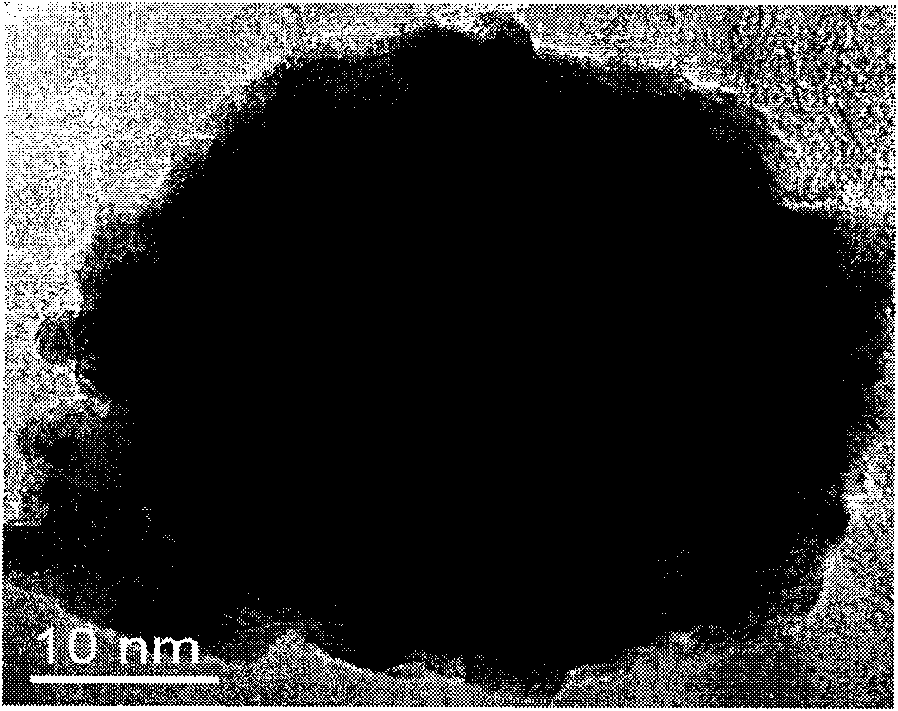

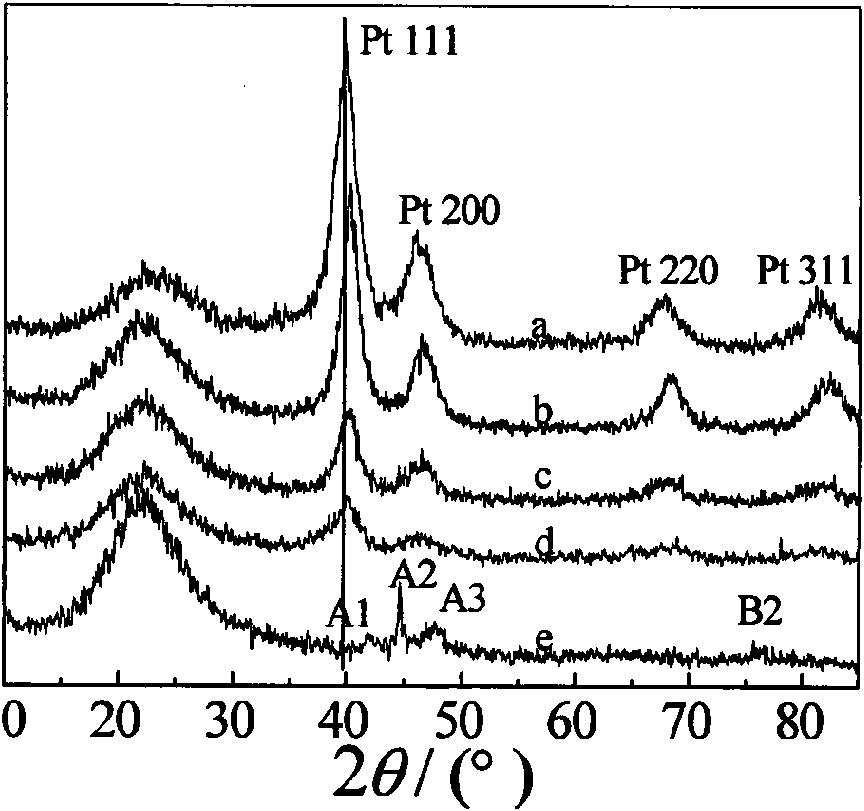

[0021] 2) Re-dissolve the Co nanoparticles in the above step (1) in 80ml of ethylene glycol, add 40mg of polyvinylpyrrolidone (PVP) under stirring, and then add 0.0386mol L -1 H 2 PtCl 6 Solution 1.28ml, continue to stir at 60°C, then add 20 drops·min -1 Dropping at a rate of 1mol·L -1 NaOH ethylene glycol solution adjusts the pH value to 13 and the concentration to 0.1mol L -1 0.47ml of hydrazine hydrate solution, the molar ratio of hydrazine hydrate to platinum atom i...

Embodiment 2

[0024] 1) Add 100ml ethylene glycol into the reactor, pass nitrogen for 30min, then add 3.0mmol CoCl 2 ·6H 2 O, 1000mg polyvinylpyrrolidone (PVP), stirring at 65°C and continuing to feed nitrogen, then adding a concentration of 0.3mol L -1 , with 1mol L -1 NaOH aqueous solution adjusts 5ml of hydrazine hydrate solution whose pH value is 13, and the dropping rate is 40 drops·min -1 , continue to stir and react for 60min, prepare Co nano catalyst sol, and then filter to obtain Co nanoparticles;

[0025] 2) Re-dissolve the Co nanoparticles in the above (1) in 80ml of ethanol, add 250mg of polyvinylpyrrolidone (PVP) under stirring, and then add 0.0386mol L -1 H 2 PtCl 6 Solution 9.6ml, continue to stir at 70°C, then add 30 drops·min -1 Dropping at a rate of 1mol·L -1 NaOH ethylene glycol solution adjusts the pH value to 13 and the concentration to 0.1mol L -1 9.3ml of hydrazine hydrate solution, the molar ratio of hydrazine hydrate to platinum atoms is 2.5:1, and the stirr...

Embodiment 3

[0028] 1) Add 100ml of water into the reactor, pass nitrogen for 30min, then add 1.0mmol CoCl 2 ·6H 2 O, 500mg polyvinylpyrrolidone (PVP), stirring at 65°C and continuing to feed nitrogen, then adding a concentration of 0.3mol L -1 , with 1mol L -1 NaOH aqueous solution adjusts 1.7ml of hydrazine hydrate solution whose pH value is 13, and the dropping rate is 40 drops·min -1 , continue to stir and react for 60min, prepare Co nano catalyst sol, and then filter to obtain Co nanoparticles;

[0029] 2) Re-dissolve the Co nanoparticles in the above (1) in 80ml of ethanol, add 250mg of polyvinylpyrrolidone (PVP) under stirring, and then add 0.0386mol L -1 H 2 PtCl 6 Solution 12.8ml, continue to stir at 70°C, then add 30 drops.min -1 Dropping at a rate of 1mol·L -1 NaOH ethylene glycol solution adjusts the pH value to 13 and the concentration to 0.1mol L -1 12.4ml of hydrazine hydrate solution, the molar ratio of hydrazine hydrate to platinum atom is 2.5:1, continue to stir a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com