System and method for automatically separating solid from liquid by self-thermal high-temperature aerobic digestion of mud

A high-temperature aerobic digestion and automatic separation technology, applied in chemical instruments and methods, sludge treatment, sludge treatment, etc., can solve the problems of high-temperature digestion bacteria reflux, slow heating of the system, slowness, etc., and achieve low VOC emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

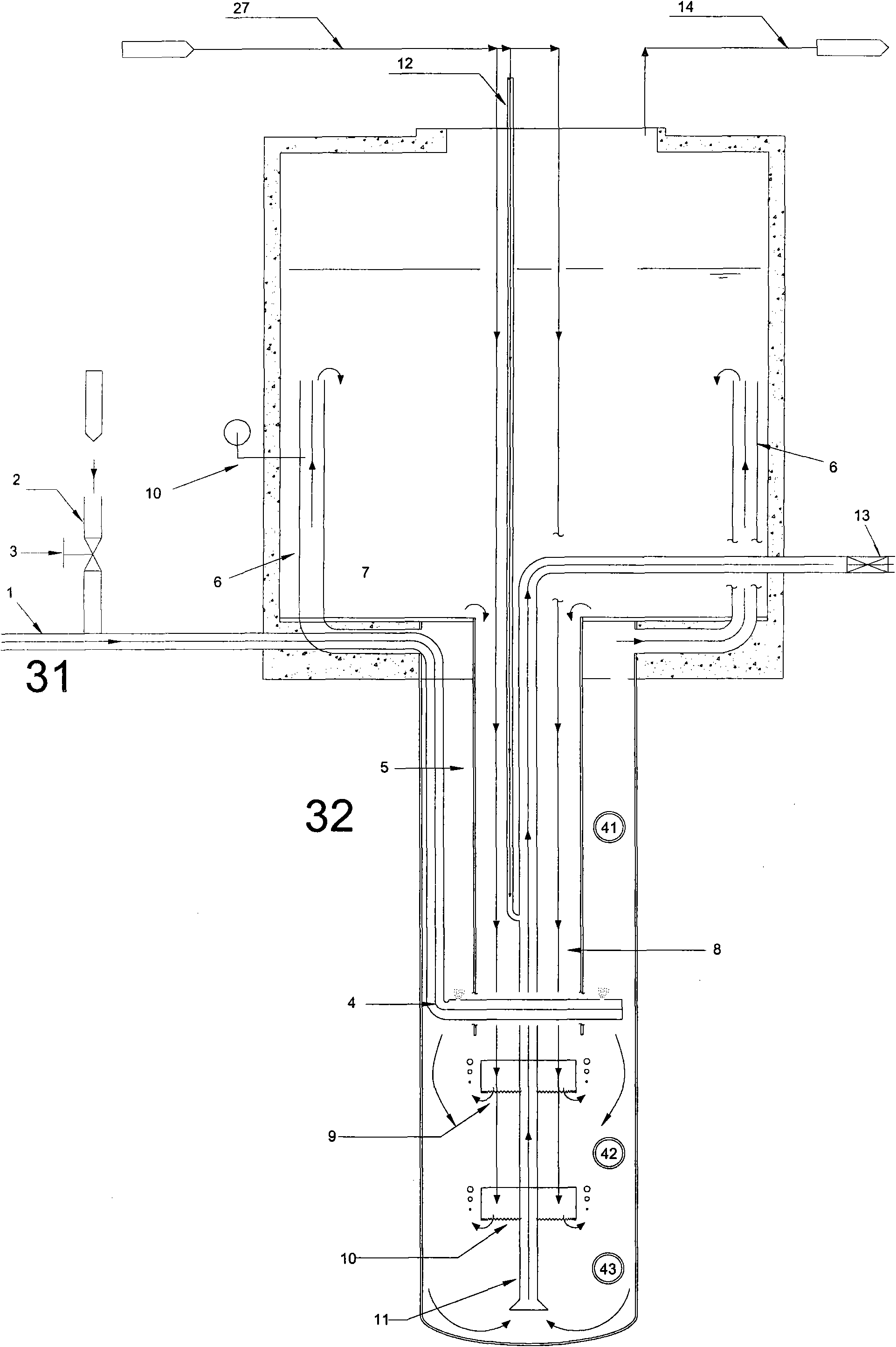

[0092] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

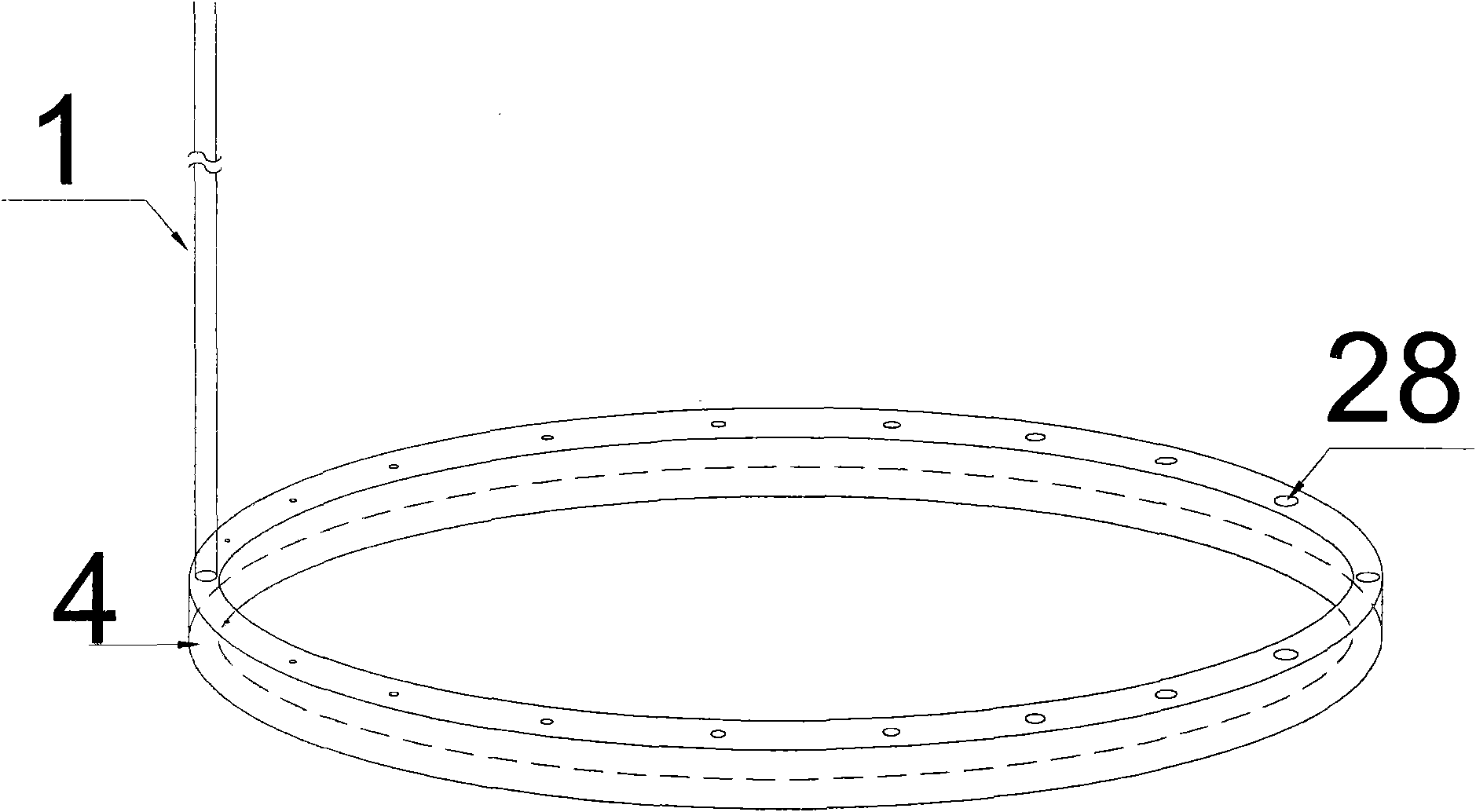

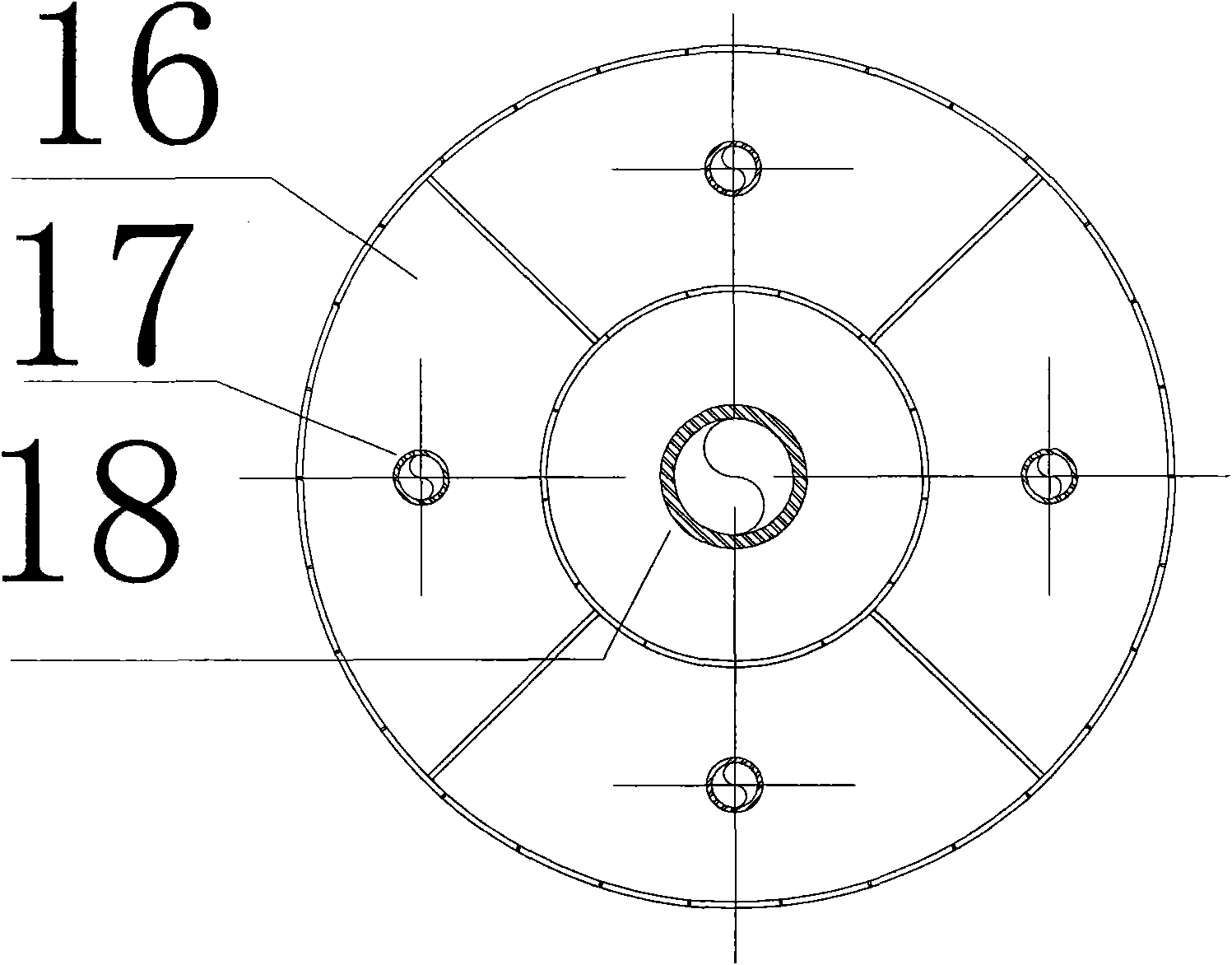

[0093] figure 1 As shown, the present embodiment includes a sludge aerobic digestion reaction device, which is referred to as "well type internal circulation sludge aerobic digestion reaction device" in the present invention, comprising a steel cylinder hidden in the ground (along the outer wall of the steel cylinder) Concrete retaining wall), an above-ground top pool placed on the top of the steel cylinder, is called the top degassing pool 7.

[0094] The underground reaction steel cylinder contains three independent functional areas of hydraulic separation, which respectively implement unit operations for sludge digestion and virus killing. These three areas are called internal cycle areas 41 (Internal Cycle Zone, hereinafter ICZ for short), the complete-mixing zone 42 (Complete-mixing Zone, CMZ) and the high-temperature sterilization zone 43 (Pasteuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com