Crystalline form of hydrochlorothiazide and application thereof

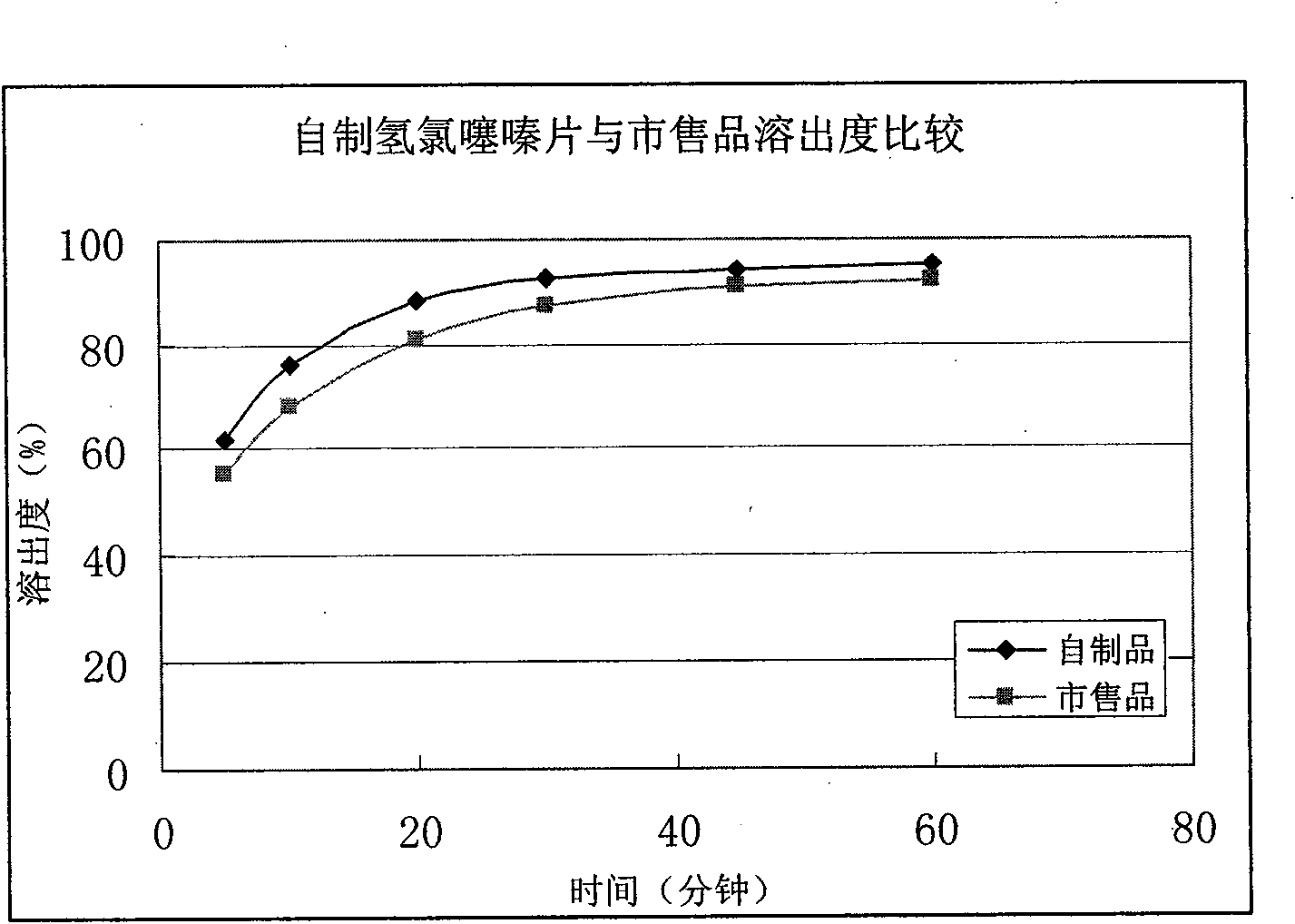

A technology of hydrochlorothiazide and crystal form, which is applied in the field of medicinal chemistry, can solve the problems of slow dissolution of hydrochlorothiazide and poor production utilization, and achieve the effects of improving dissolution effect, solving slow dissolution speed and effective therapeutic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Hydrochlorothiazide Tablets

[0040] components

quantity

25g

60g

48.5g

Low-substituted hydroxypropyl cellulose

7g

povidone k30

8g

Micropowder silica gel

0.75g

0.75g

[0041] Preparation method: sieve the raw and auxiliary materials for later use; take hydrochlorothiazide, microcrystalline cellulose, starch, mannitol, sodium carboxymethyl starch, and low-substituted hydroxypropyl cellulose and mix evenly; then add micronized silica gel and magnesium stearate Mix well; tablet that is.

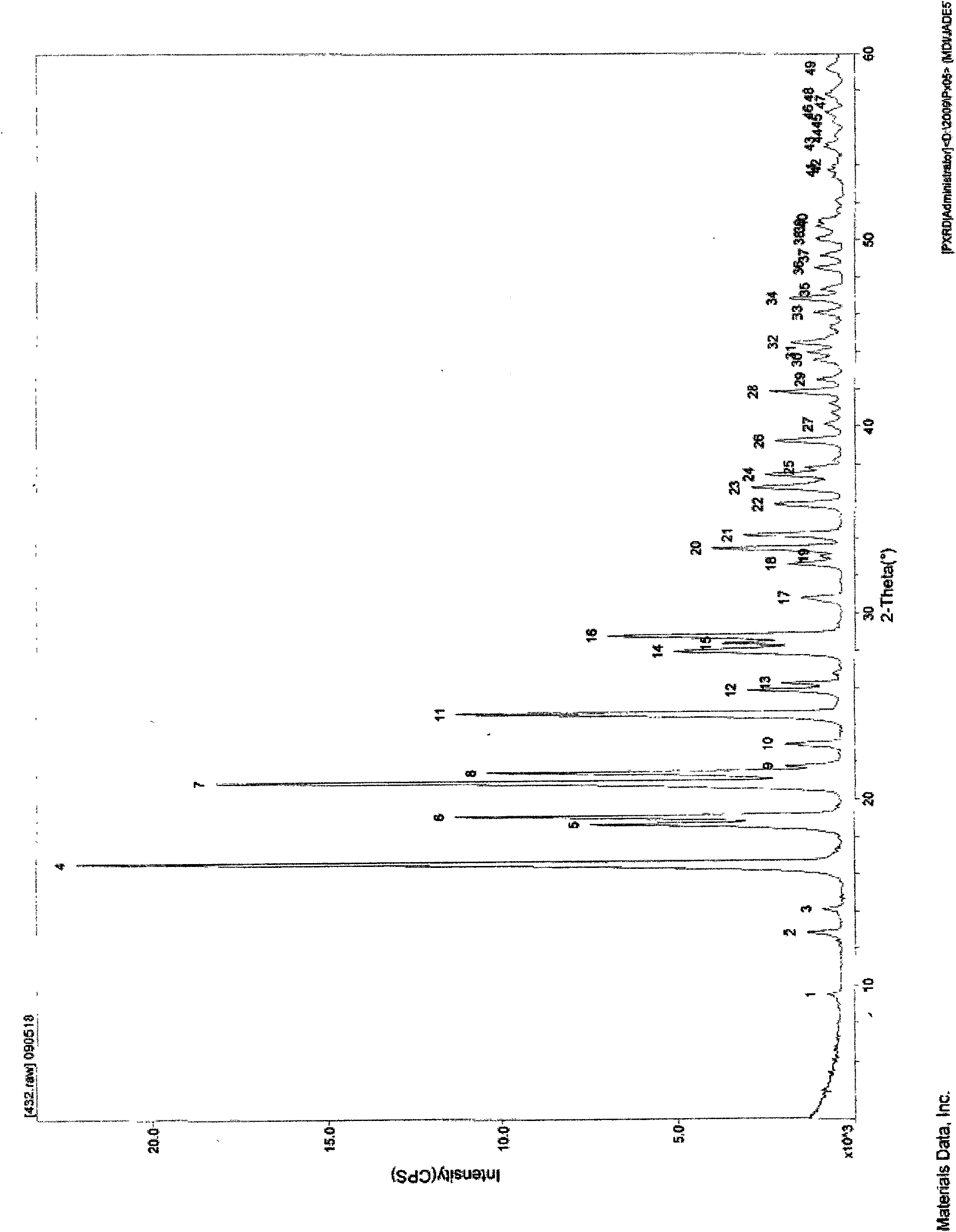

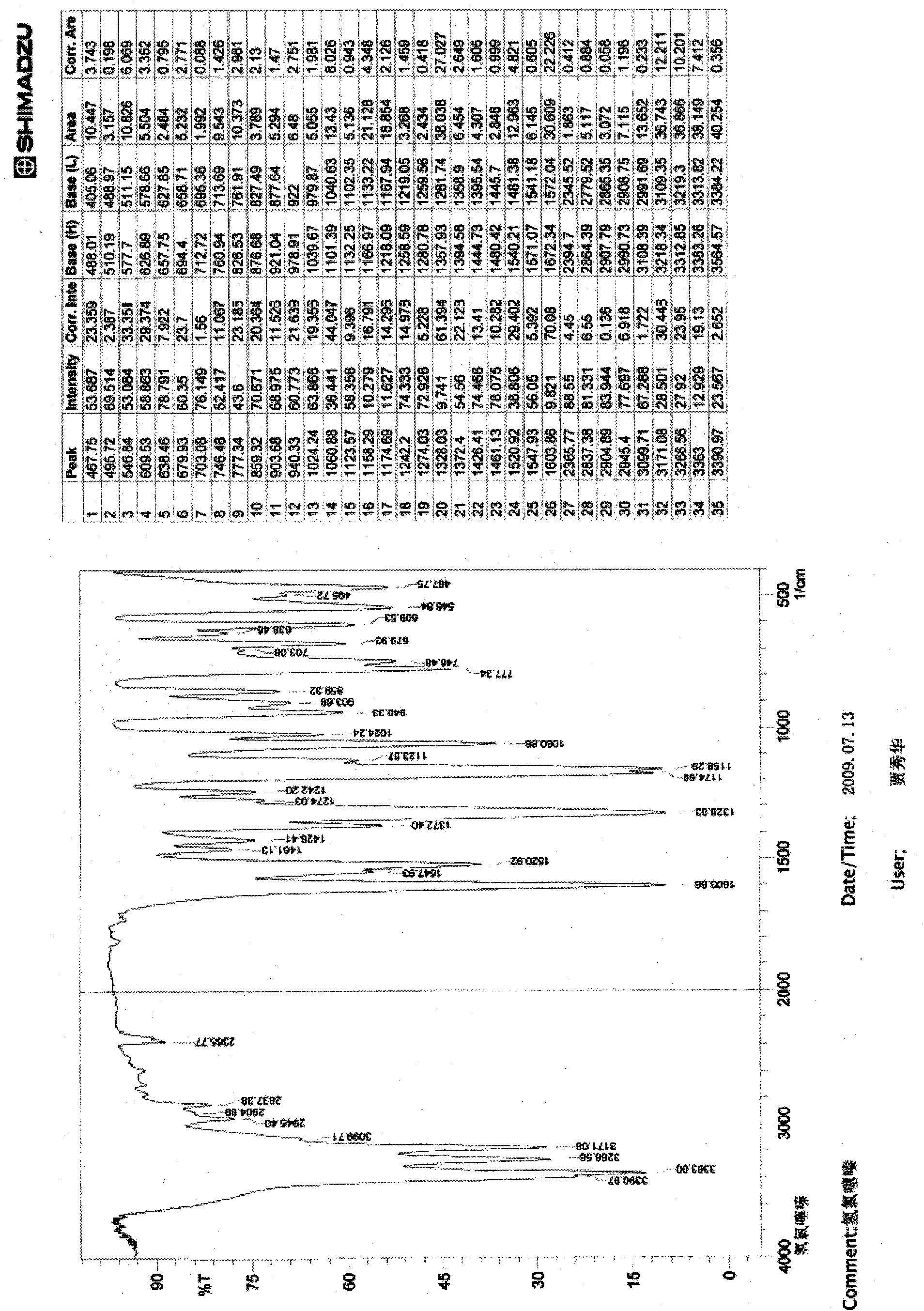

[0042] The preparation method of hydrochlorothiazide is as follows: dissolve 100 g of hydrochlorothiazide in 500 ml of 4% sodium hydroxide aqueous solution, add dropwise 10% hydrochloric acid, precipitate hydrochlorothiazide crystals, suction filter, and dry the product to obtain hydrochlorothiazide cryst...

Embodiment 2

[0044] Valsartan Hydrochlorothiazide Tablets

[0045] components

quantity

80g

Hydrochlorothiazide

12.5g

60g

30g

10g

1g

10% povidone k30

20ml

[0046] Preparation method: take valsartan, hydrochlorothiazide, starch, and microcrystalline cellulose and sieve separately for later use; the above-mentioned raw and auxiliary materials are mixed and mixed evenly when passing through a 100-mesh sieve; Granulate with a mesh sieve; dry the granules in a drying oven at 50°C; add sodium carboxymethyl starch and magnesium stearate to mix, pass through a 18-mesh sieve for granulation; compress into tablets; coat plain tablets to obtain the product.

[0047] The preparation method of hydrochlorothiazide is as follows: dissolve 100 g of hydrochlorothiazide in 250 ml of 5% sodium hydroxide aq...

Embodiment 3

[0049] Irbesartan Hydrochlorothiazide Capsules

[0050] components

quantity

150g

Hydrochlorothiazide

12.5g

starch

30g

40g

25g

Crospovidone

10g

Magnesium stearate

1.5g

5% povidone k30 aqueous solution

40ml

[0051] Preparation method: sieve each raw and auxiliary material for later use; take irbesartan, hydrochlorothiazide, starch, microcrystalline cellulose, lactose, and cross-linked povidone and mix evenly; add 5% povidone solution in the prescribed amount to make a soft material ; Sieve through a 40-mesh granulation; dry the granules in a drying oven at 50°C; add magnesium stearate to the dry granules, pass through a 30-mesh granule; pack the granules into capsules.

[0052] The preparation method of hydrochlorothiazide is as follows: dissolve 100 g of hydrochlorothiazide in 1000 ml of an aqueous solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com