Manufacturing method of light emitting diode (LED) based on inversed roughened surface Gan-base vertical structure

A technology of light-emitting diodes and vertical structures, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low light extraction efficiency, sapphire substrate, low insulation and low thermal conductivity, and low efficiency of GaN-based light-emitting devices, so as to improve the internal quantum efficiency , high luminous efficiency, and the effect of improving the quality of the crystal lattice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] A method for manufacturing a GaN-based vertical structure light-emitting diode based on an inverted rough surface, the process of which is implemented as follows:

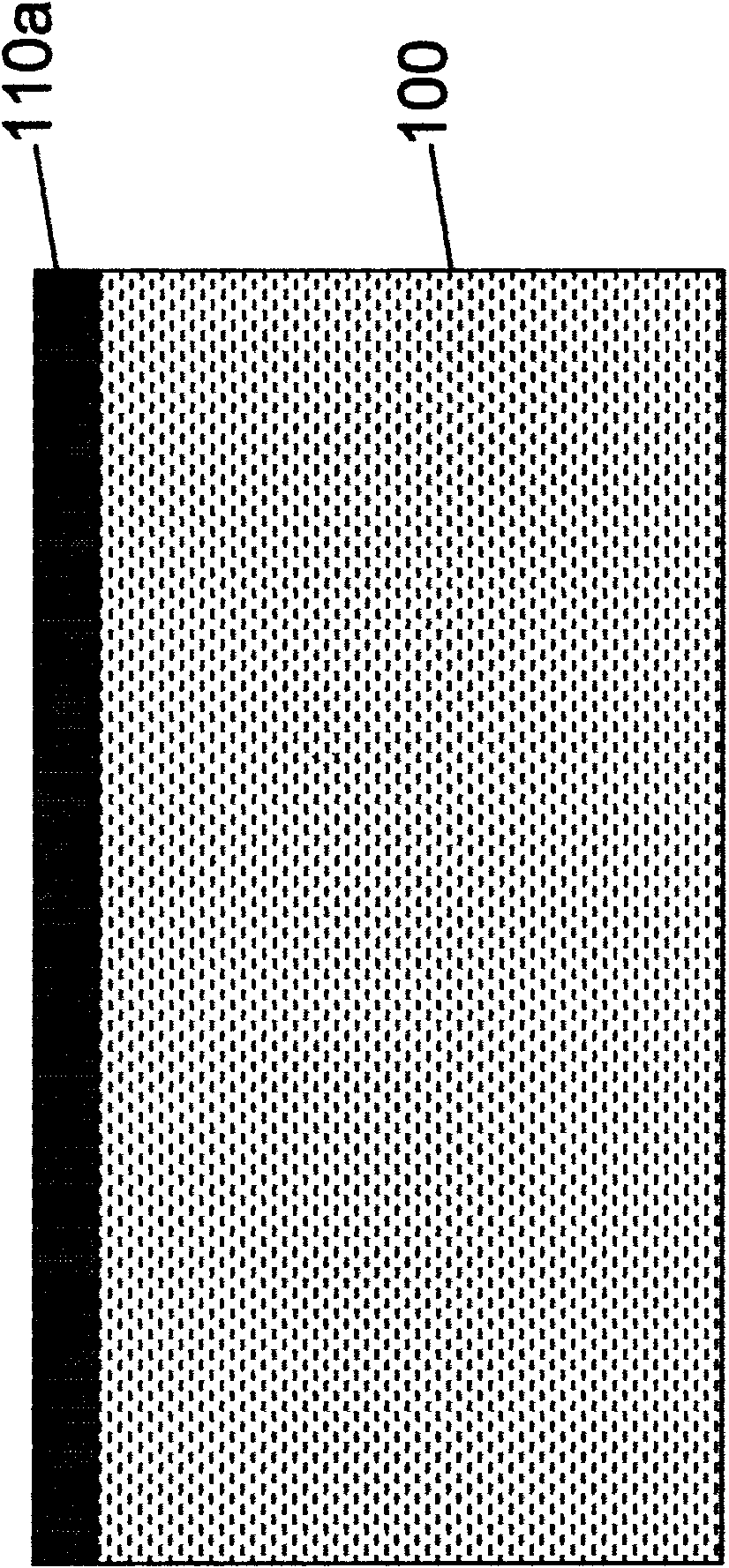

[0034] like Figure 1a As shown, an undoped GaN material layer 110a with a thickness of 2 microns is epitaxially grown on a sapphire substrate 100 by MOCVD method;

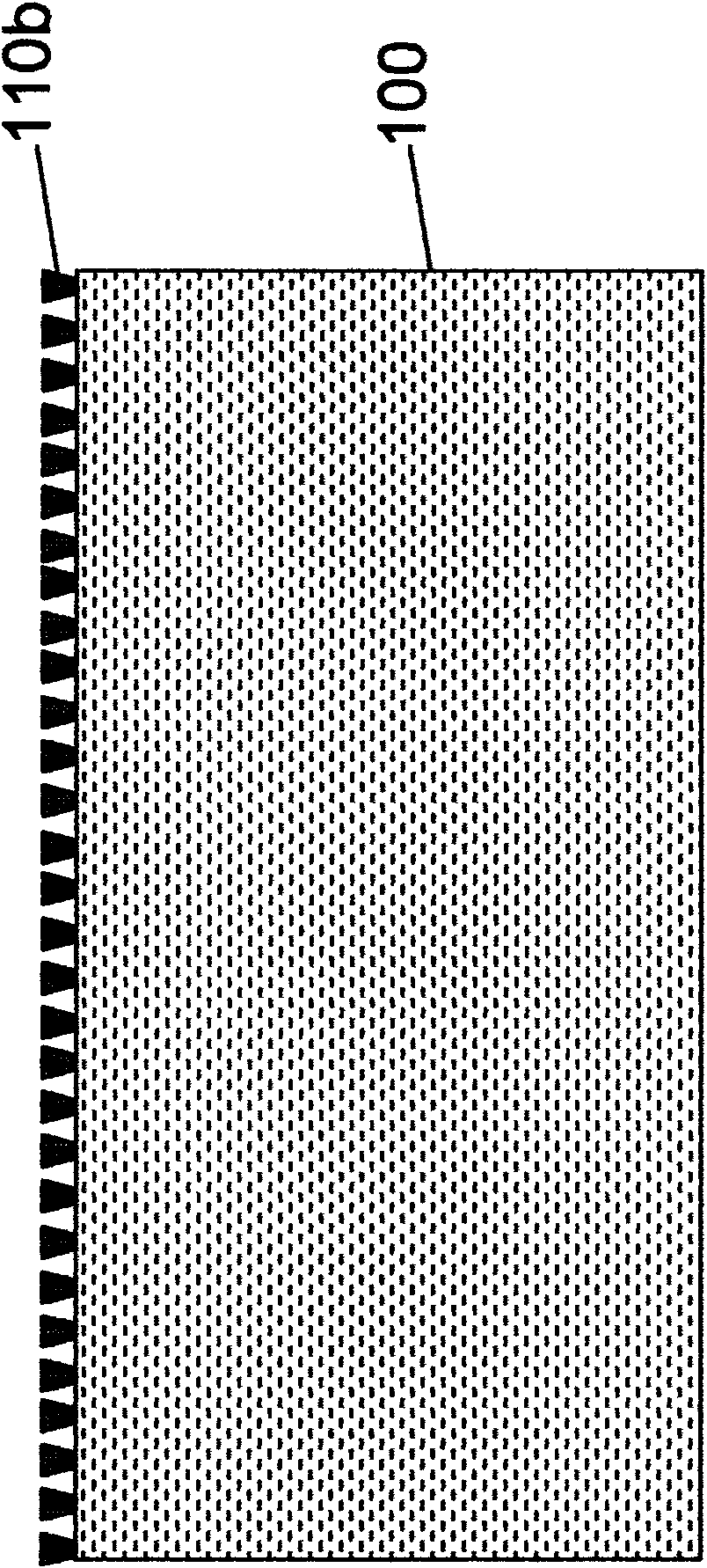

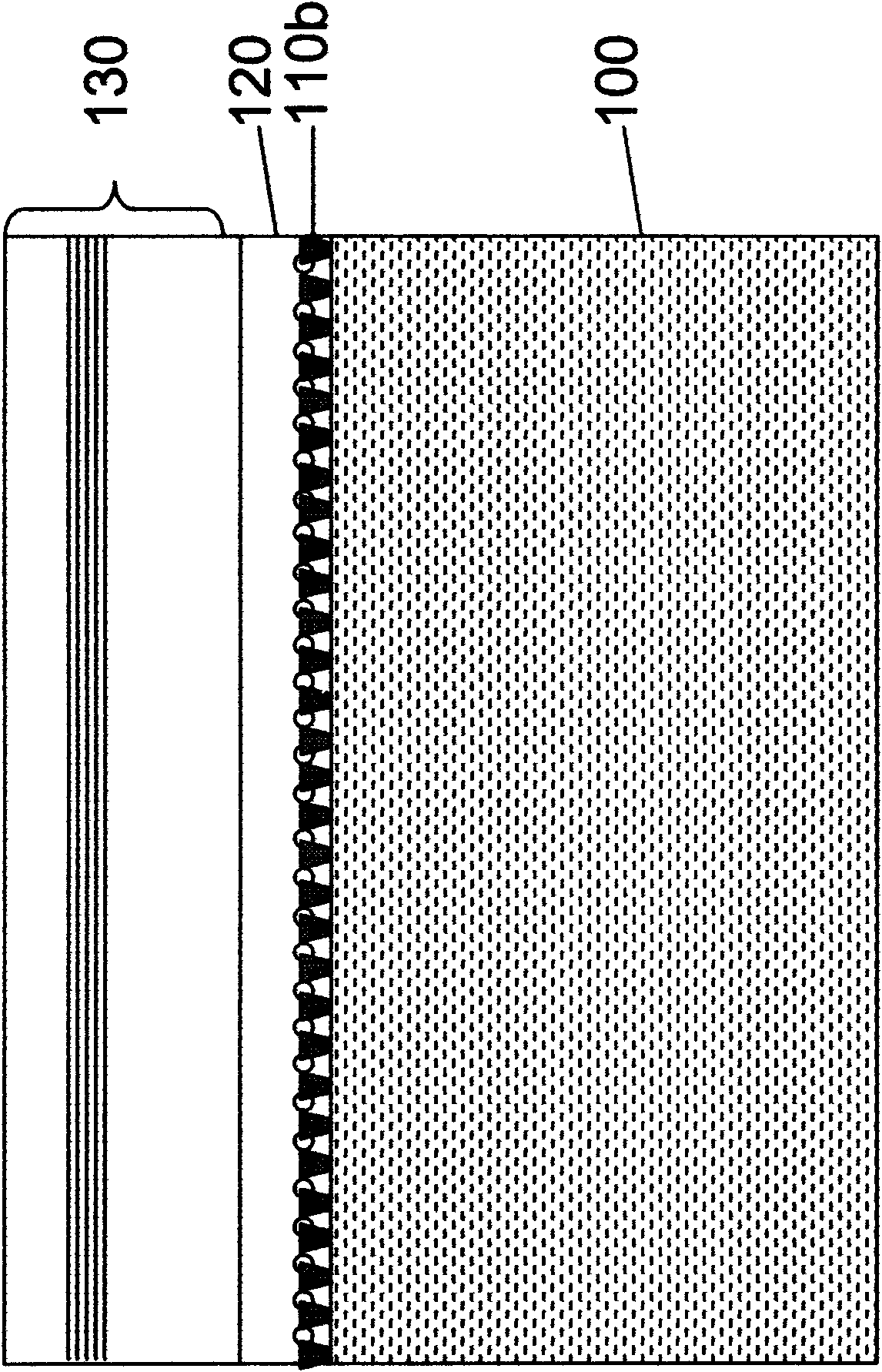

[0035] like Figure 1b As shown, the wafer prepared in step 1 is immersed in a high-temperature molten KOH solution. The temperature of the KOH solution is heated to 280° C., and the etching time lasts for 10 minutes. The undoped GaN material layer 110a is anisotropic in the high-temperature molten KOH solution. Etching forms several inverted hexagonal rhomboid grooves, the opening diameter of the hexagonal rhomboid grooves is between 1 micron and 3 microns, and a discontinuous gap is formed between the bottom of the un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com