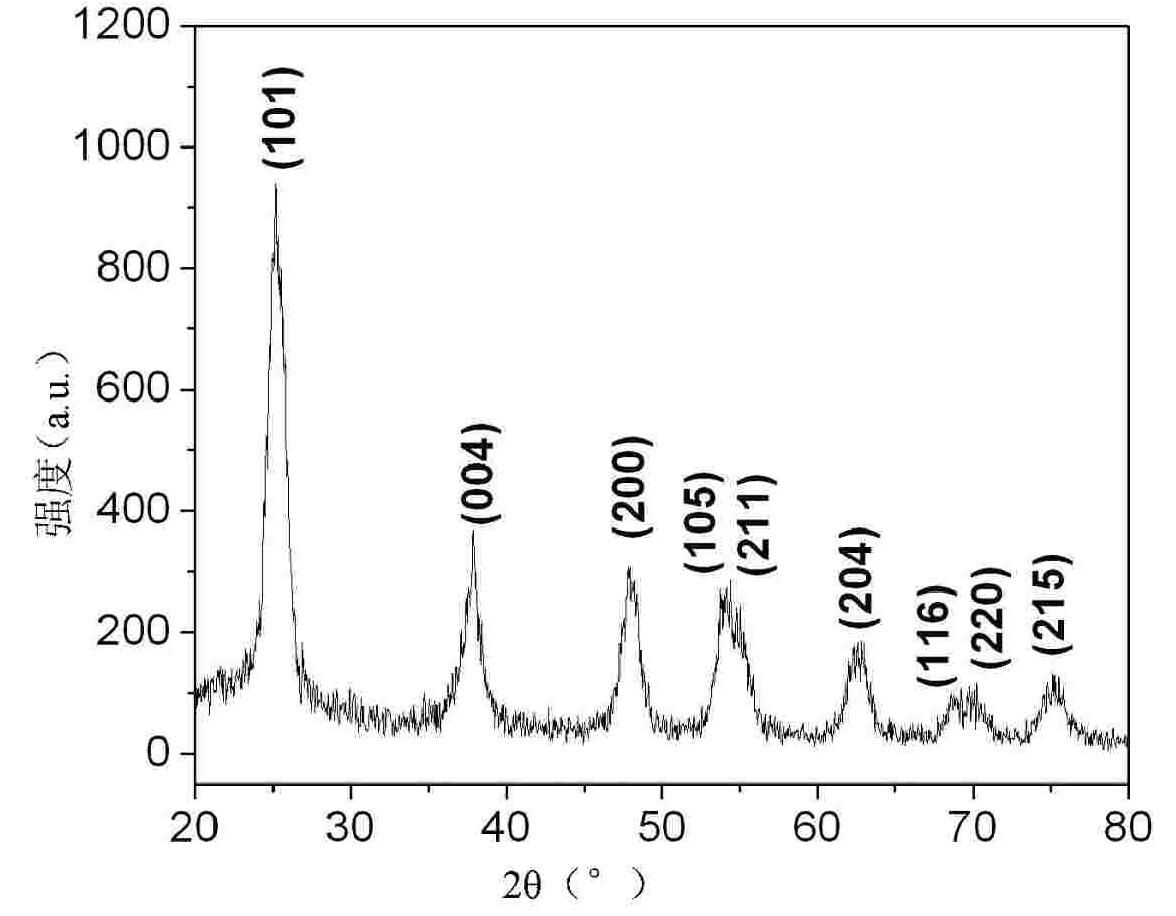

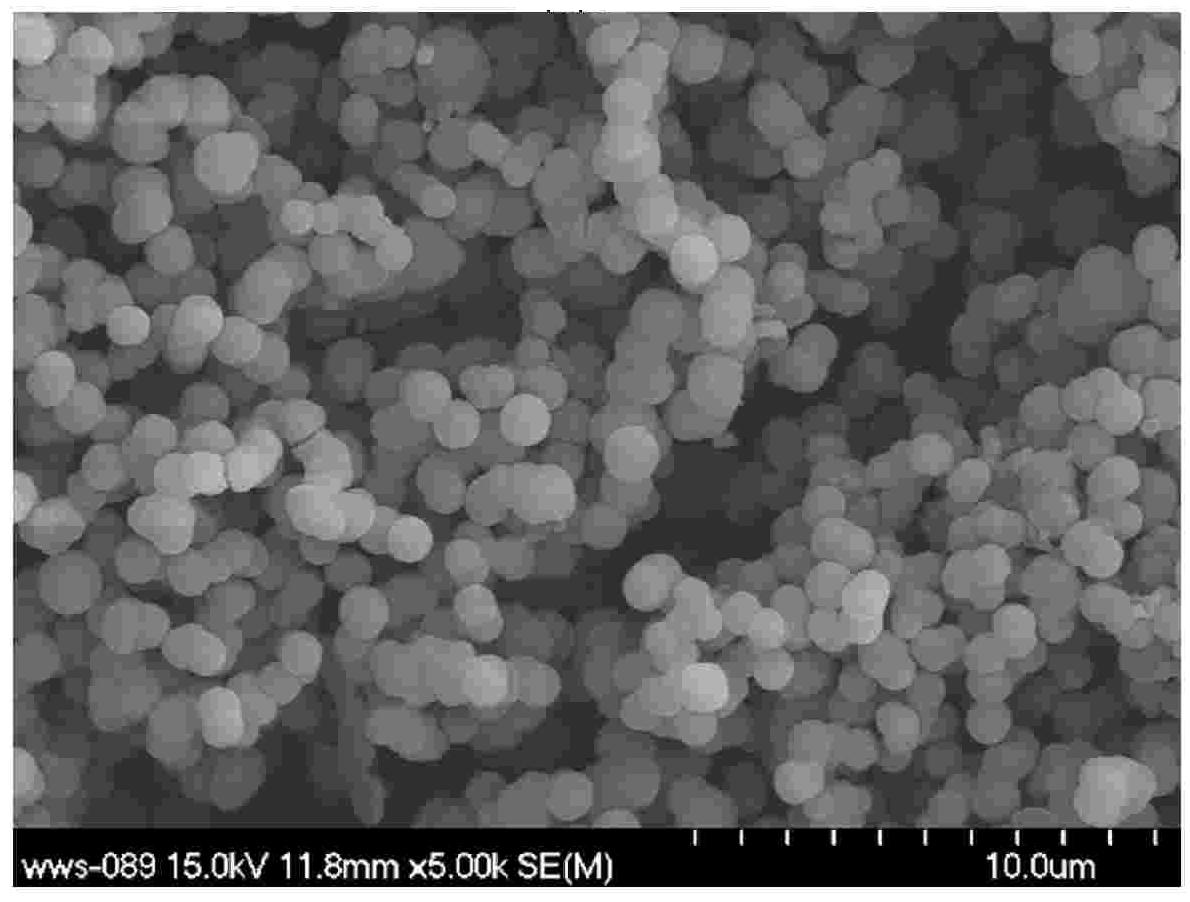

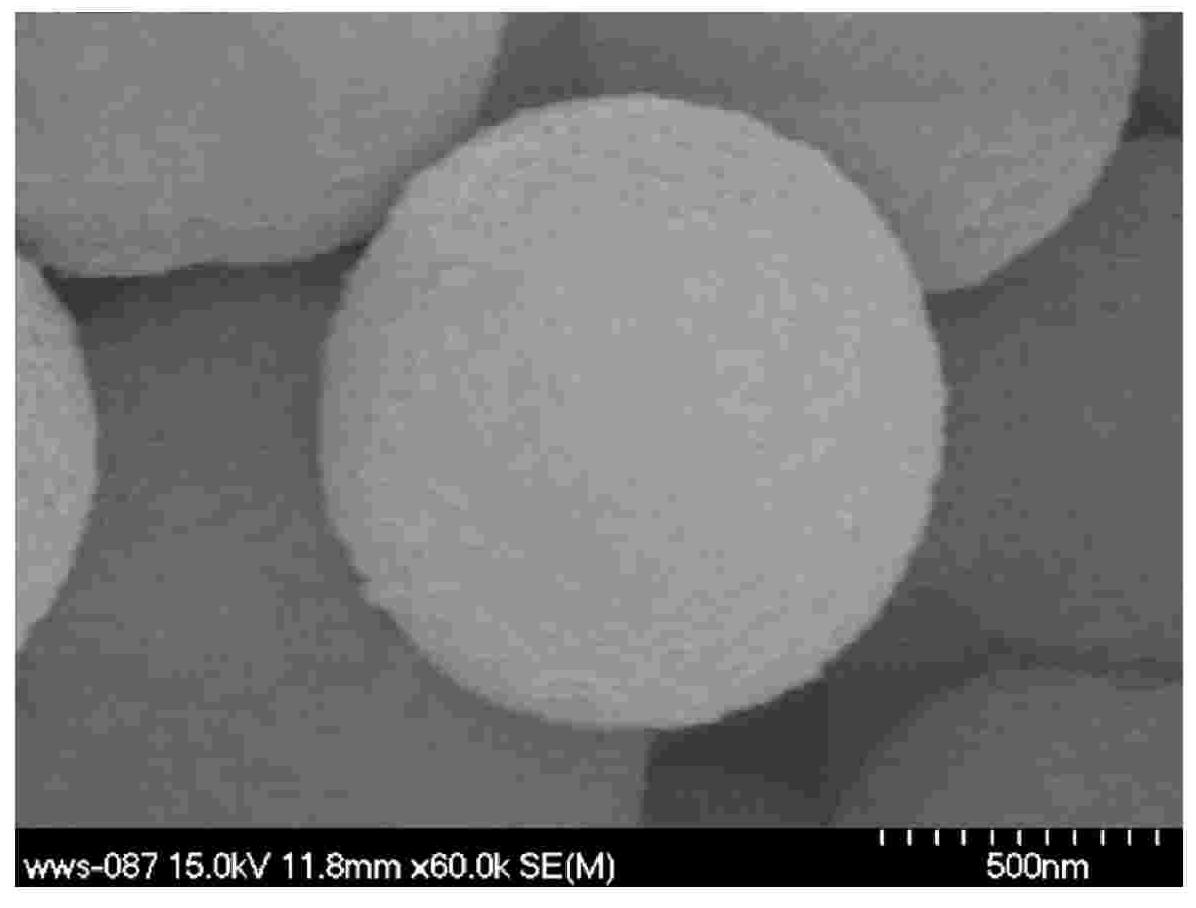

Method for preparing anatase-TiO2 porous microspheres

A technology of titanium dioxide and porous microspheres, which is applied in the directions of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of complicated production process of porous microspheres, high temperature in the preparation process, and expensive precursors, etc., and achieves operability and repeatability. It has strong properties, low hydrothermal reaction temperature, and the effect of improving photocatalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Embodiment 1: The method for preparing anatase titanium dioxide porous microspheres in this embodiment is carried out according to the following steps: 1. Dissolve 0.16 to 0.2 parts of titanium sulfate dihydrate into 48 to 52 parts of distilled water according to the ratio of parts by weight Obtain titanium sulfate dihydrate solution; 2. Put the titanium sulfate dihydrate solution into a polytetrafluoroethylene high-pressure tank, and then move the polytetrafluoroethylene high-pressure tank into a blast oven at 115-125°C for drying for 45-52 hours. The white precipitate obtained after natural cooling to room temperature; 3. Wash the white precipitate alternately with distilled water and absolute ethanol for 2 to 10 times, and then dry the white precipitate at 55 to 63°C for 6 to 10 hours to obtain anatase Mineral-type titanium dioxide porous microspheres.

[0011] The concentration of the titanium sulfate dihydrate solution in Step 1 of this embodiment is 0.014-0.016M. ...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment differs from Embodiment 1 in that the titanium sulfate dihydrate in step 1 is chemically pure. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0016] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, 0.18 parts of titanium sulfate dihydrate is dissolved in 50 parts of distilled water according to the ratio of parts by weight. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com