Pre-separation method of C5 diene for distilling off methyl butane for two times

A technology of isoprene and diolefin, applied in the field of pre-separation of C5 raw materials, can solve the problems of large loss of isoprene, high concentration of isoprene, difficult to control cyclopentadiene content, etc. The effect of control and full recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

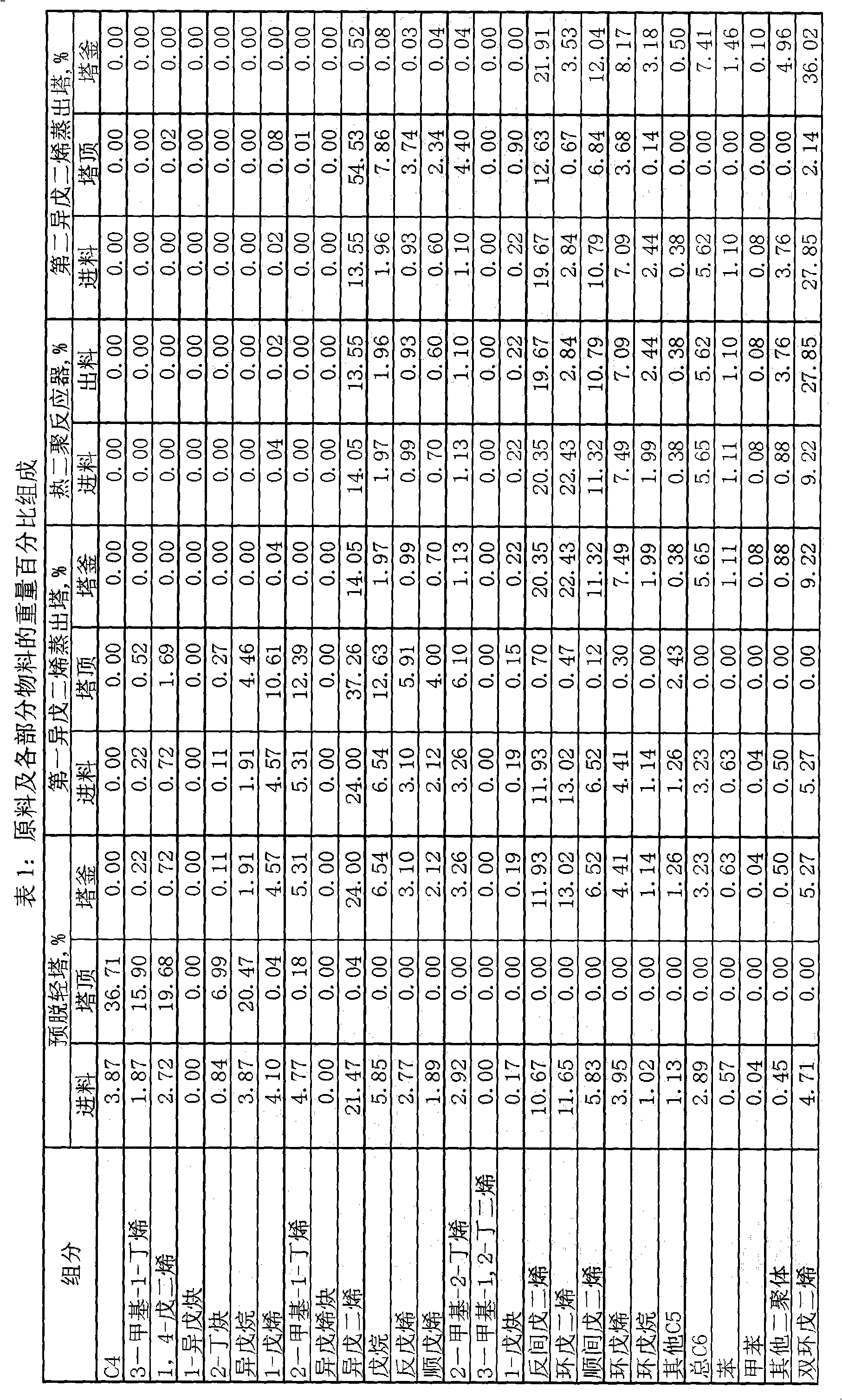

Embodiment 1

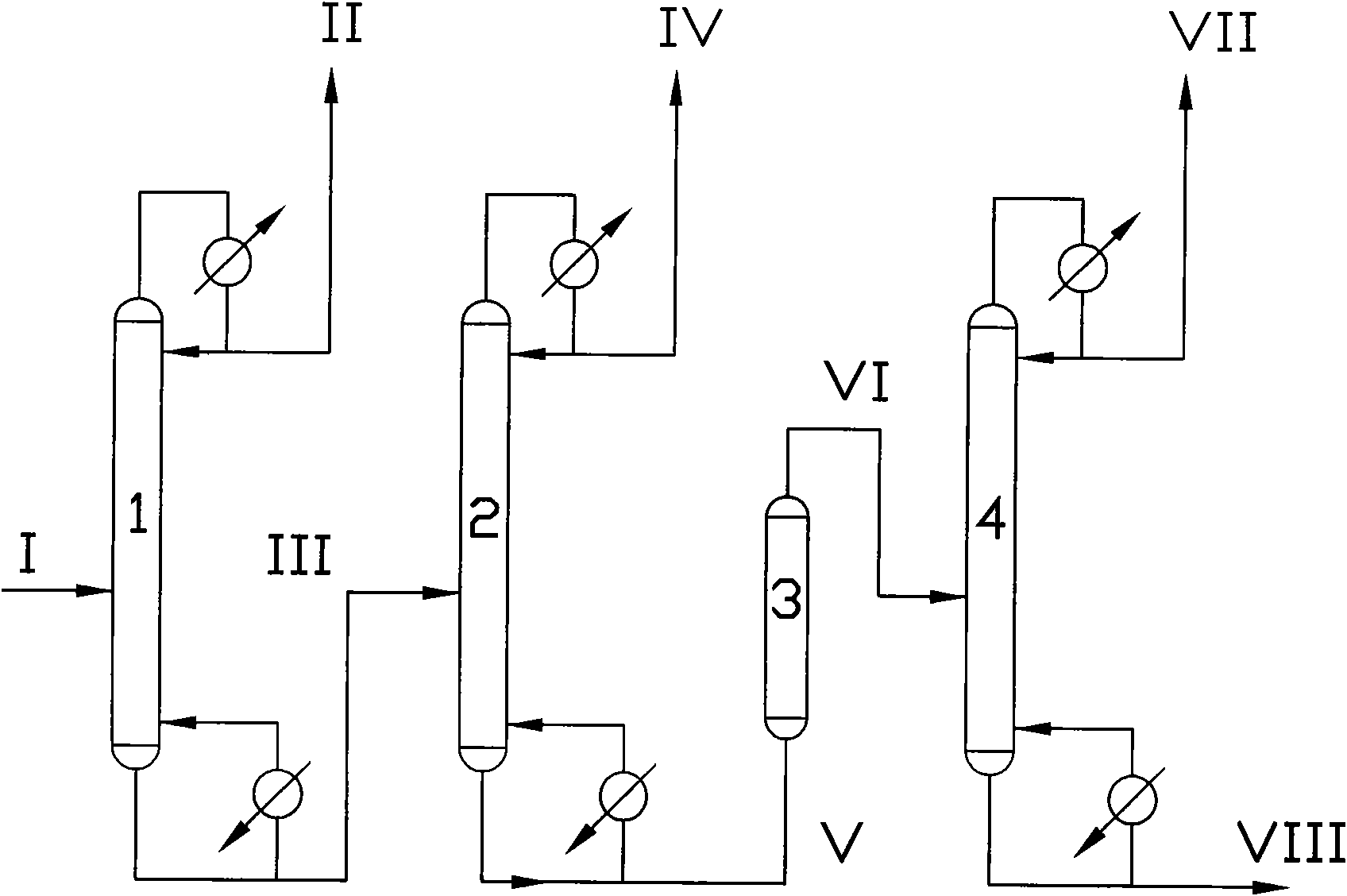

[0032] according to figure 1 The process flow, the carbon five raw material I enters the 55th tray of the pre-light removal tower 1, and the light component stream II obtained at the top of the tower is sent out to the system; the tower reactor obtains the material III after removing the light component, and sends it The first isoprene distills out of column 2. The feed temperature of the pre-delightening tower 1 is 60-70°C, the number of trays is 90, the temperature at the top of the tower is 55-60°C, the temperature at the bottom of the tower is 85-90°C, the pressure at the top of the tower is 0.3-0.35MPa, and the reflux ratio is 35.

[0033] The tower bottom material III of the pre-delightening tower 1 enters the 40th plate of the first isoprene distillation tower 2, and the stream IV rich in isoprene is obtained at the top of the tower, and is sent to the subsequent extraction and rectification process; the tower bottom obtains Material V is sent to thermal dimerization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com