Method for preparing chitosan into water-soluble chitosan oligosaccharide

A technology of water-soluble chitosan oligosaccharide and chitosan, applied in the production of sugar, sugar production, food science and other directions, can solve the problems of easy production of reaction by-products, difficult product quality control, affecting product purity, etc. The economy, the remarkable technological advancement, the effect of the simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

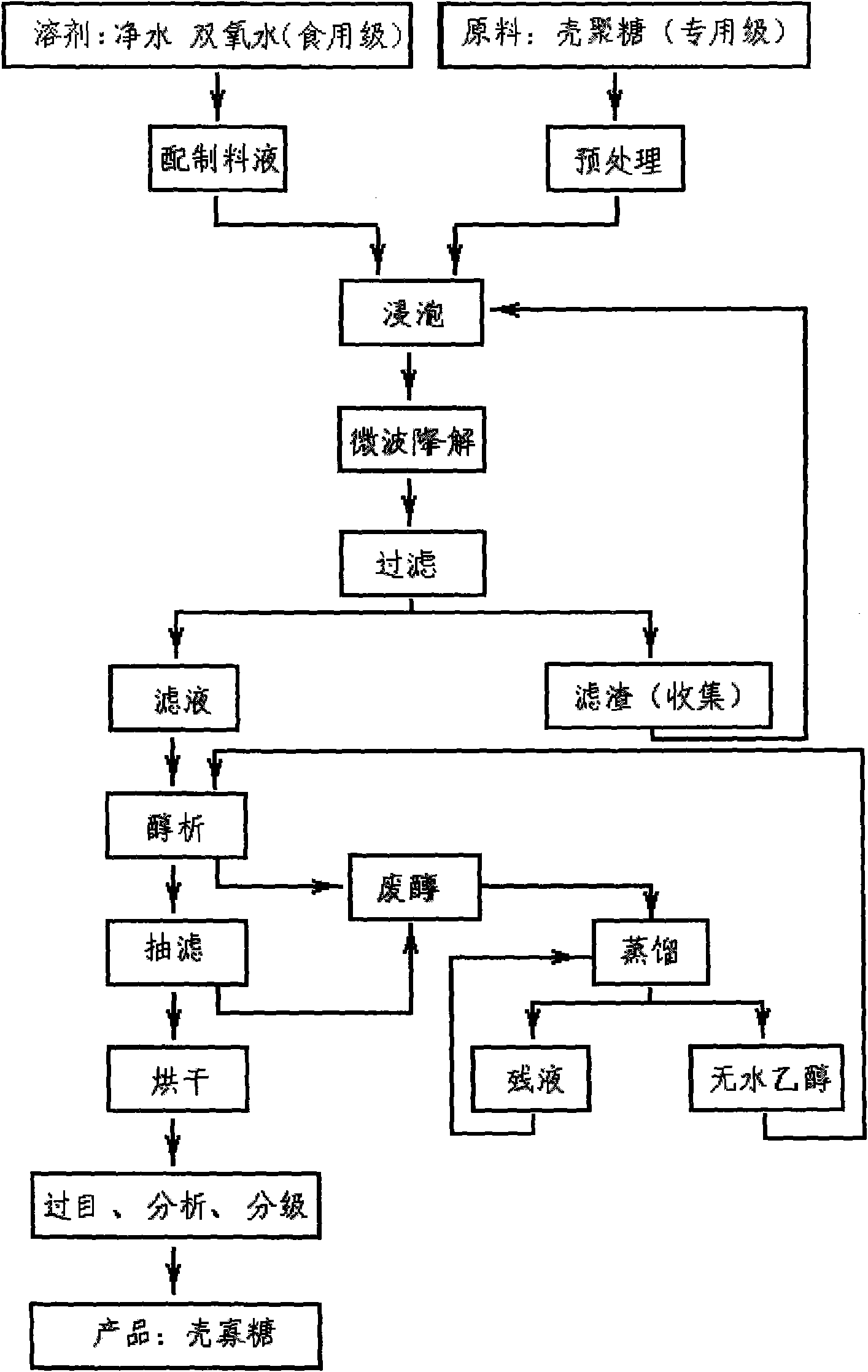

[0010] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

[0011] In the accompanying drawings, based on the method of the present invention, chitosan is prepared into water-soluble chitosan oligosaccharides, the technological process is as follows: using special-grade chitosan as raw material, after rinsing and drying process physical treatment, it is put in advance by net water (H 2 O)80-90% and food grade hydrogen peroxide (H 2 o 2 ) 10-20% by weight in the feed solution prepared by soaking for 1-2 hours; then in the microwave radiation reactor for 5-6 hours of microwave frequency radiation at a temperature lower than 80 ° C environment, most of the shell The polysaccharide can be degraded into low molecular weight, oligochitosan and a small part of undegraded chitosan residue dissolved in the feed liquid, and the undegraded chitosan residue and degraded chitosan residue are obtained after filtrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com