Plastic degrading composition, use of same and plastic and product containing same

A composition and technology for degrading plastics, applied in the field of plastics and plastic products, can solve the problems of reduced mechanical properties of plastics, not easy to degrade, and limited utilization of solar radiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

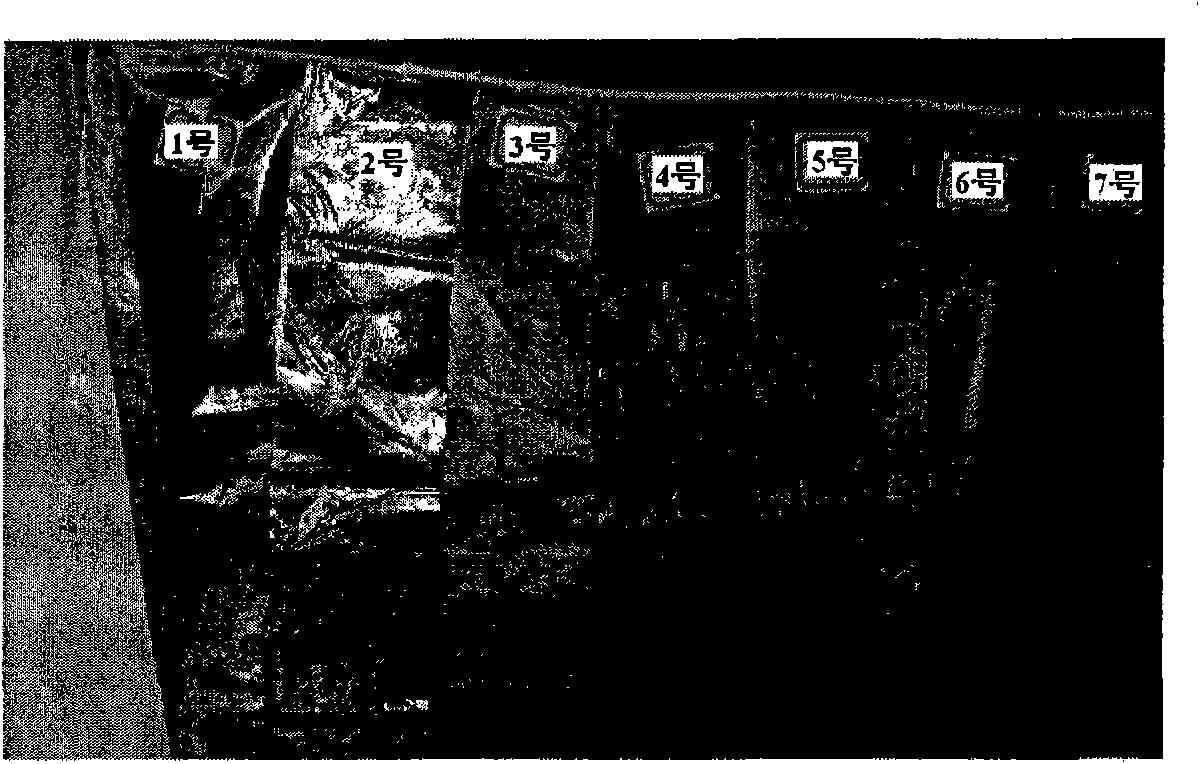

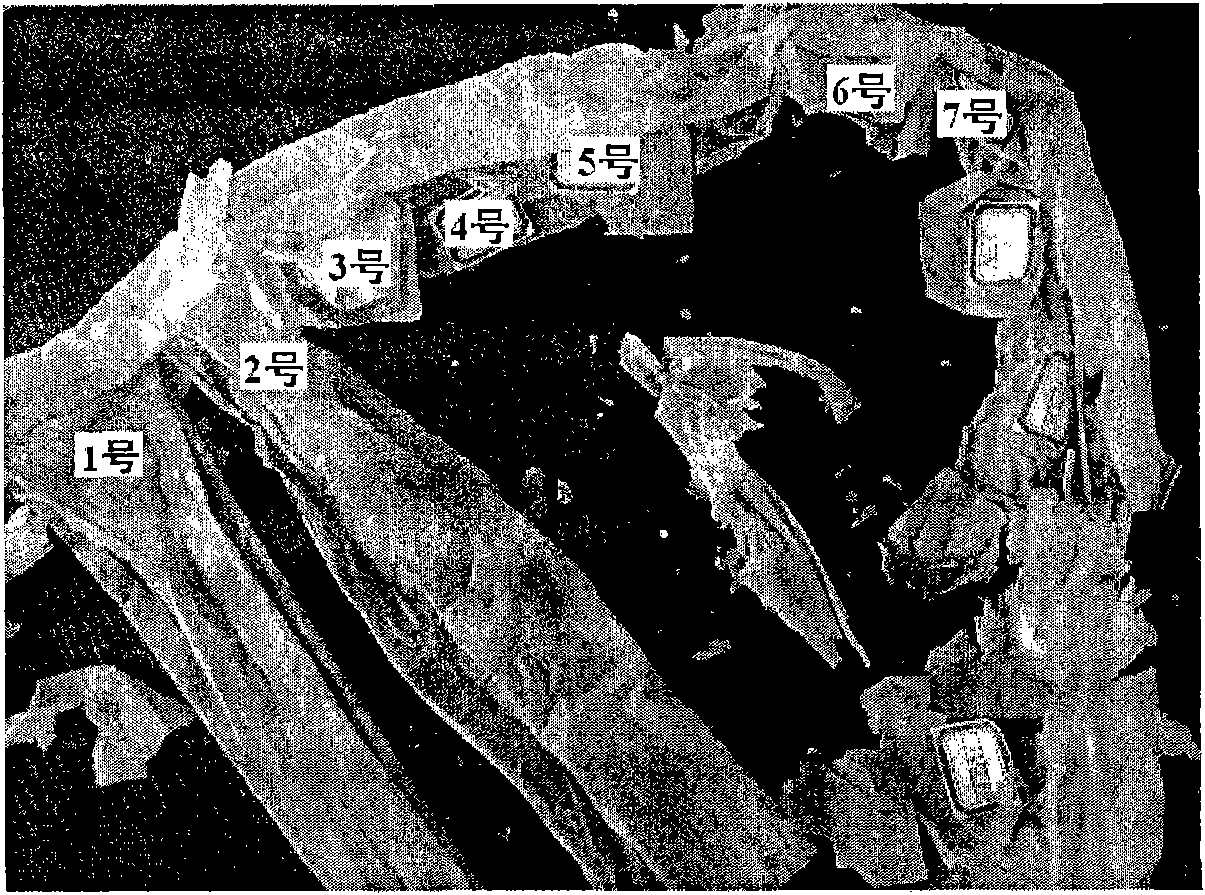

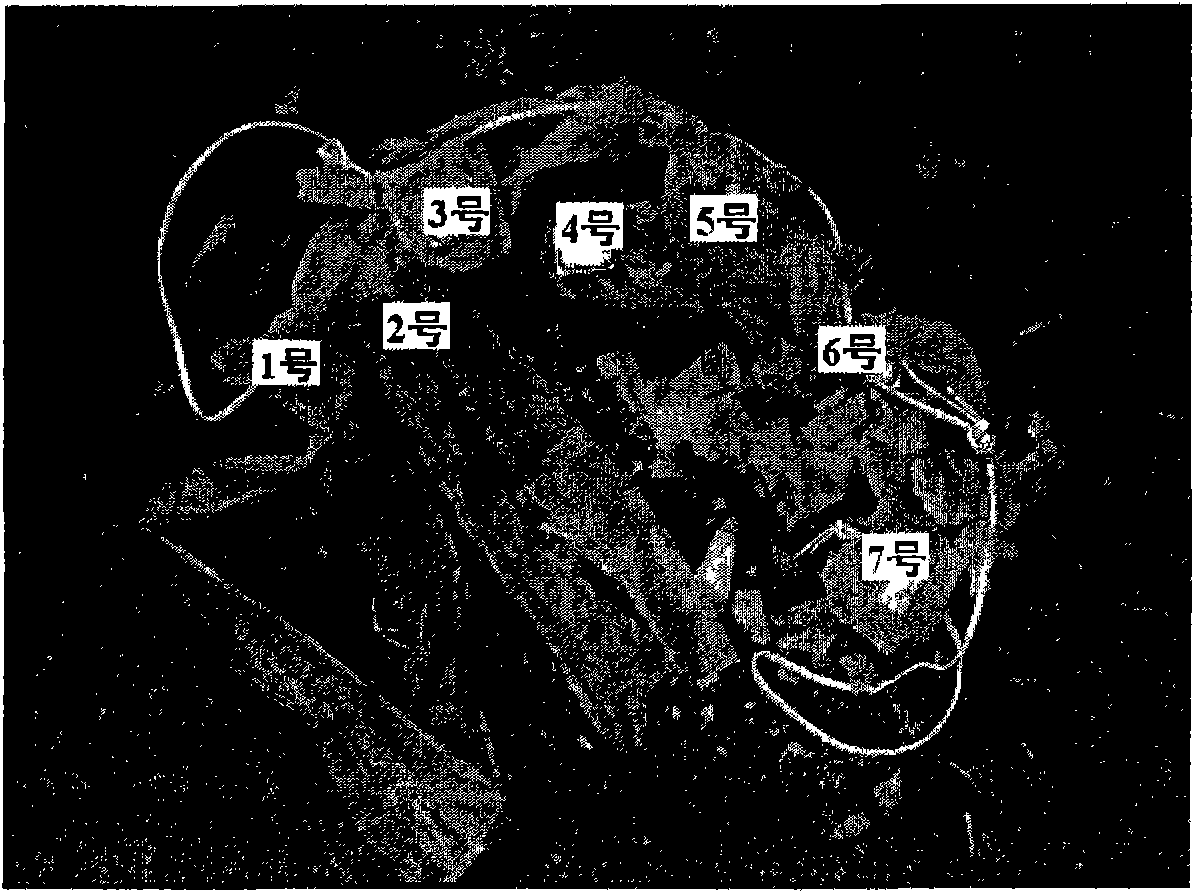

Image

Examples

Embodiment 1

[0042] Example 1 Components and dosage (percentage by weight) of the environmental degradation composition——Da Zhuang No. 1

[0043] Low-density polyethylene resin (Qilu Petrochemical TN26) 90

[0044] Nano-TiO 2 (Hangzhou Wanjing New Material Co., Ltd.) 2

[0045] Cobalt stearate (Jinan Jinletai Chemical Co., Ltd.) 6

[0046] Dibutyl hydroxytoluene (Tianjin Bodi Chemical Company) 2

[0047] Weigh various raw materials according to the above formula, and place them in a high-speed mixer and stir for 1-3 minutes. The above-mentioned mixed material was mixed with a twin-screw granulator (YD-40A / 400-22-44 / DZ, Shantou Yingdong Electric Co., Ltd., Guangdong Province, with a length-to-diameter ratio of 25:1, and the temperature of each extrusion section was 50-250°C, the rotation speed of the extruder is 25-450 rpm) to extrude and granulate.

Embodiment 2

[0048] Example 2 Components and dosage (percentage by weight) of the environmental degradation composition——Da Zhuang No. 2

[0049] LDPE resin 88

[0050] Nano-TiO 2 1

[0051] Cobalt decanoate (Tianjin Bodi Chemical Company) 8

[0052] Citric acid (Jinan Jinletai Chemical Co., Ltd.) 3

[0053] According to the above formula, various raw materials were weighed, and placed in a high-speed mixer (YD-GH-100A / DZ, Shantou Yingdong Electric Co., Ltd., Guangdong Province) to stir for 1-3 minutes. The above-mentioned mixed material is extruded with a twin-screw granulator (length-to-diameter ratio 25:1, the temperature of each extrusion section is 50-250°C, and the rotation speed of the extruder is 25-450 rpm). grain.

Embodiment 3

[0054] Example 3 Disposable degradable plastic shopping bag, food bag will contain the particle of the composition of embodiment 1, join in the high-density polyethylene (Qilu Petrochemical 6098) in the ratio of 2.0 (weight percent), and the latter consumption is 98 (weight percent) ).

[0055] After uniform mixing, put the mixture into the hopper of the extrusion film blowing machine (Shenzhen Weitai Machinery Equipment Co., Ltd. SJM-45D, extruder screw diameter 45mm, aspect ratio 25:1), and then extrusion blow molding Form a cylindrical film (thickness of the film can be 0.01-0.5mm). Then, through printing, punching, heat sealing, etc., various specifications of degradable plastic shopping bags, food bags and other packaging bags are made. Its mechanical properties are similar to or improved to ordinary shopping bags and food bags of the same thickness. It meets the technical requirements of disposable plastic shopping bags and food bags. Its hygienic properties also ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com