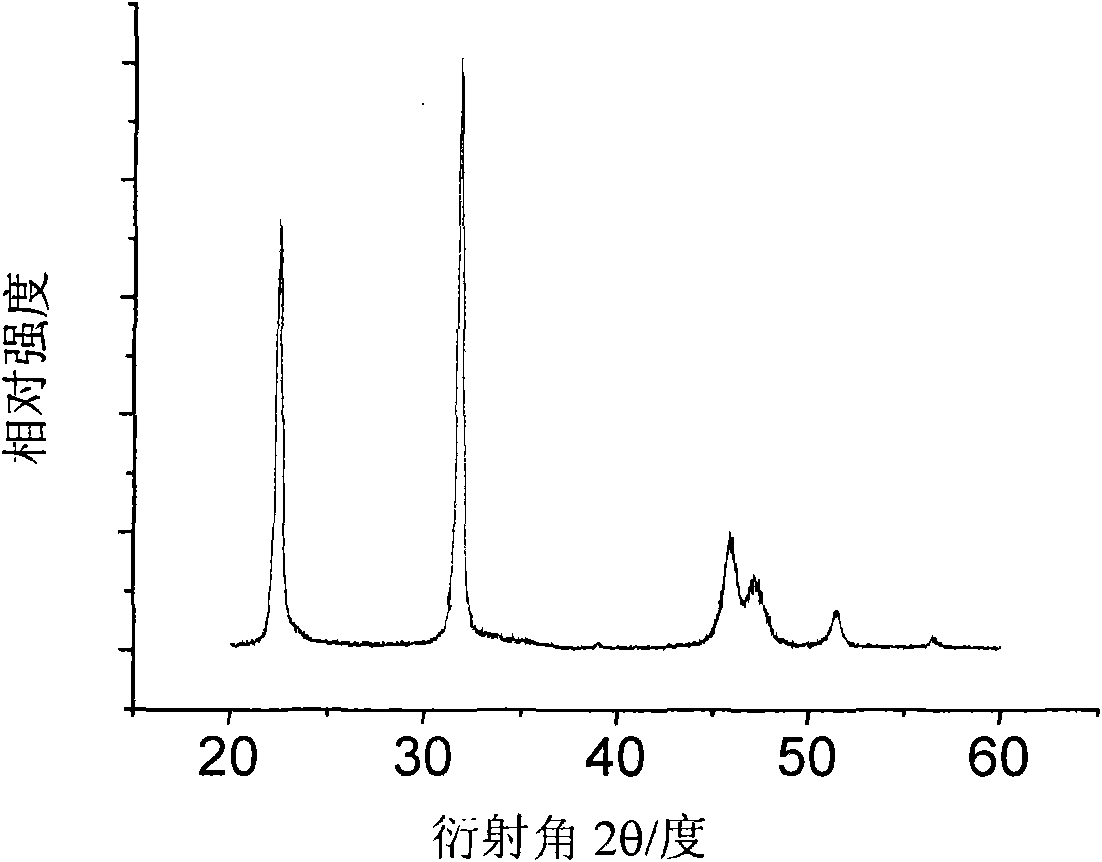

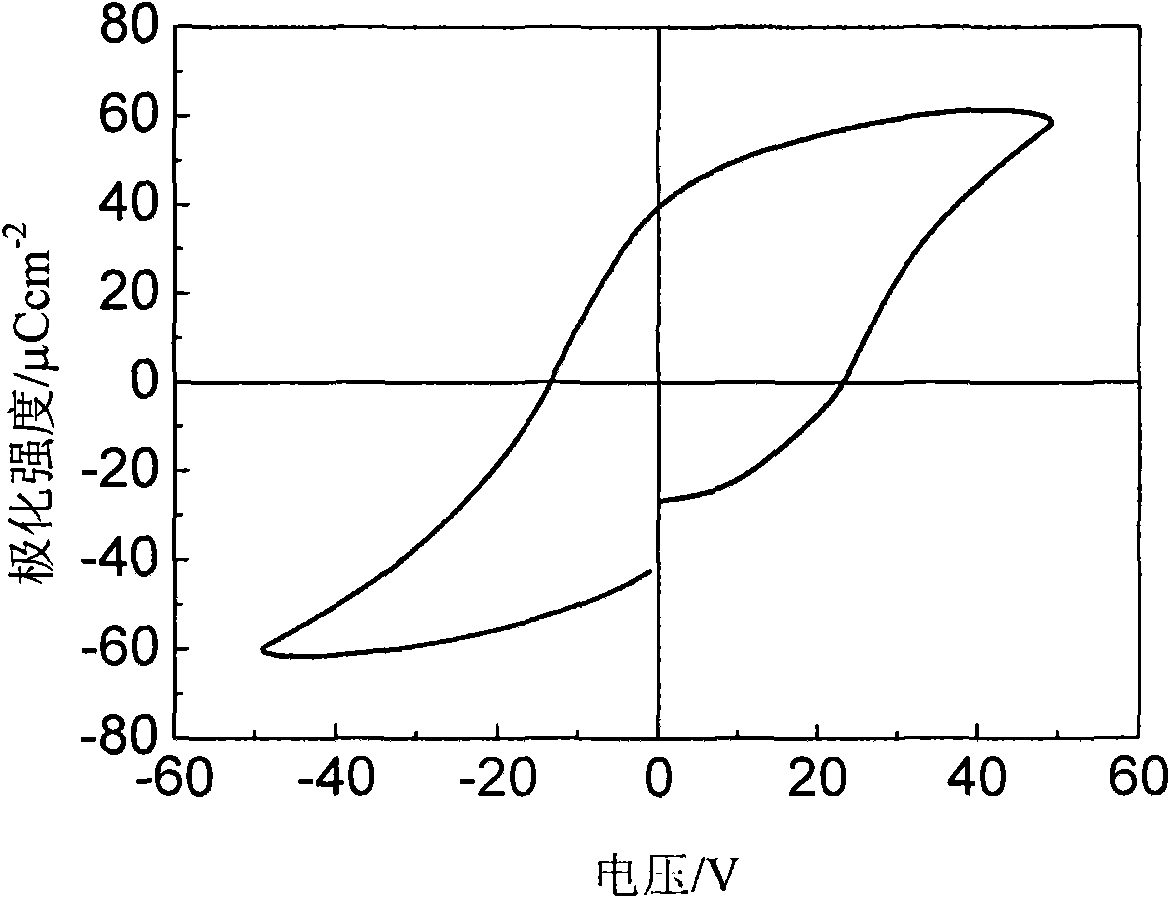

Method for preparing bismuth ferric film material

A thin film material, bismuth ferrite technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems of complex process, high production cost, and high requirements for oxide epitaxial layer equipment, and achieves the preparation method. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] a), substrate cleaning and installation

[0020] Using a (100)-oriented single crystal silicon substrate covered with LaNiO grown by chemical solution method 3 Conductive layer, the thickness of the conductive layer is about 100nm. After the substrate is washed with deionized water and absolute ethanol in sequence, it is dried with high-purity nitrogen gas and fixed on the sample tray. Vacuum the system to a vacuum of 10 -4 Pa.

[0021] b), film material preparation

[0022] Heat the substrate (sample) to keep its temperature at 650°C; feed oxygen into the system to keep the oxygen pressure in the system at 1Pa; adjust the distance between the target surface and the sample surface to 5 cm, set the target tray and The sample tray rotates in the opposite direction at a speed of 1.5 rpm; the laser ablates the target for deposition, and the target is a commercially customized bismuth ferrite target with a diameter of 5 cm and a thickness of 1 cm. Wherein the molar conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com