Special flour for food with high bulkiness and low oil content as well as manufacture method and application

A special powder and oil content technology, applied in food preparation, application, food science and other directions, can solve problems such as fluffy and low oil content, and achieve good results, increase fluffy, and reduce oil absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

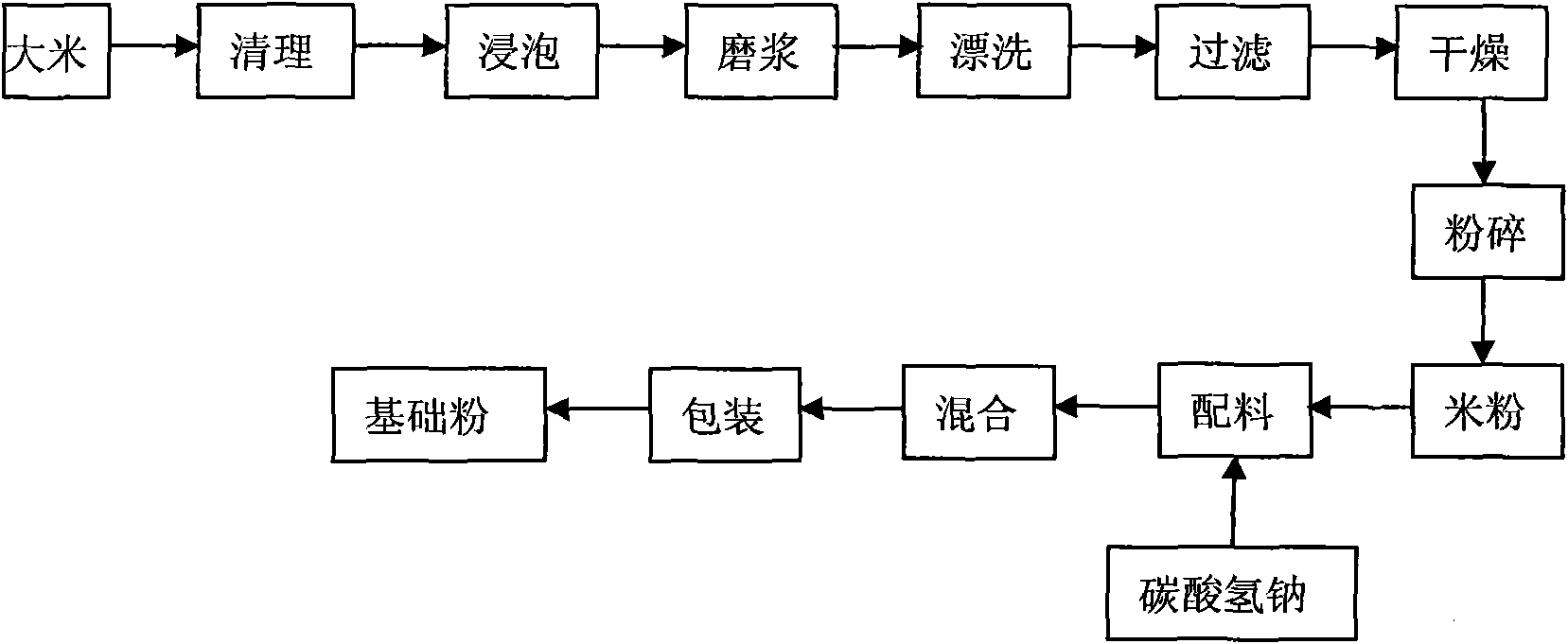

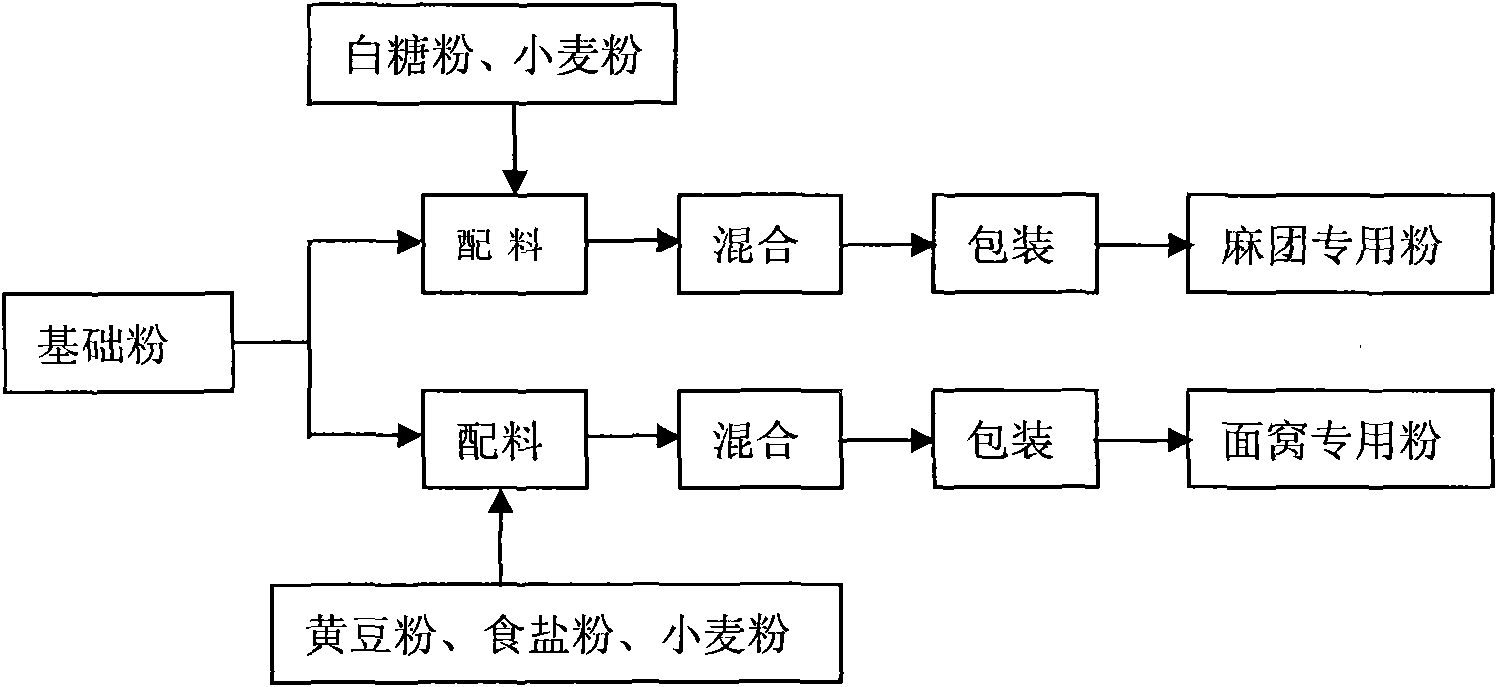

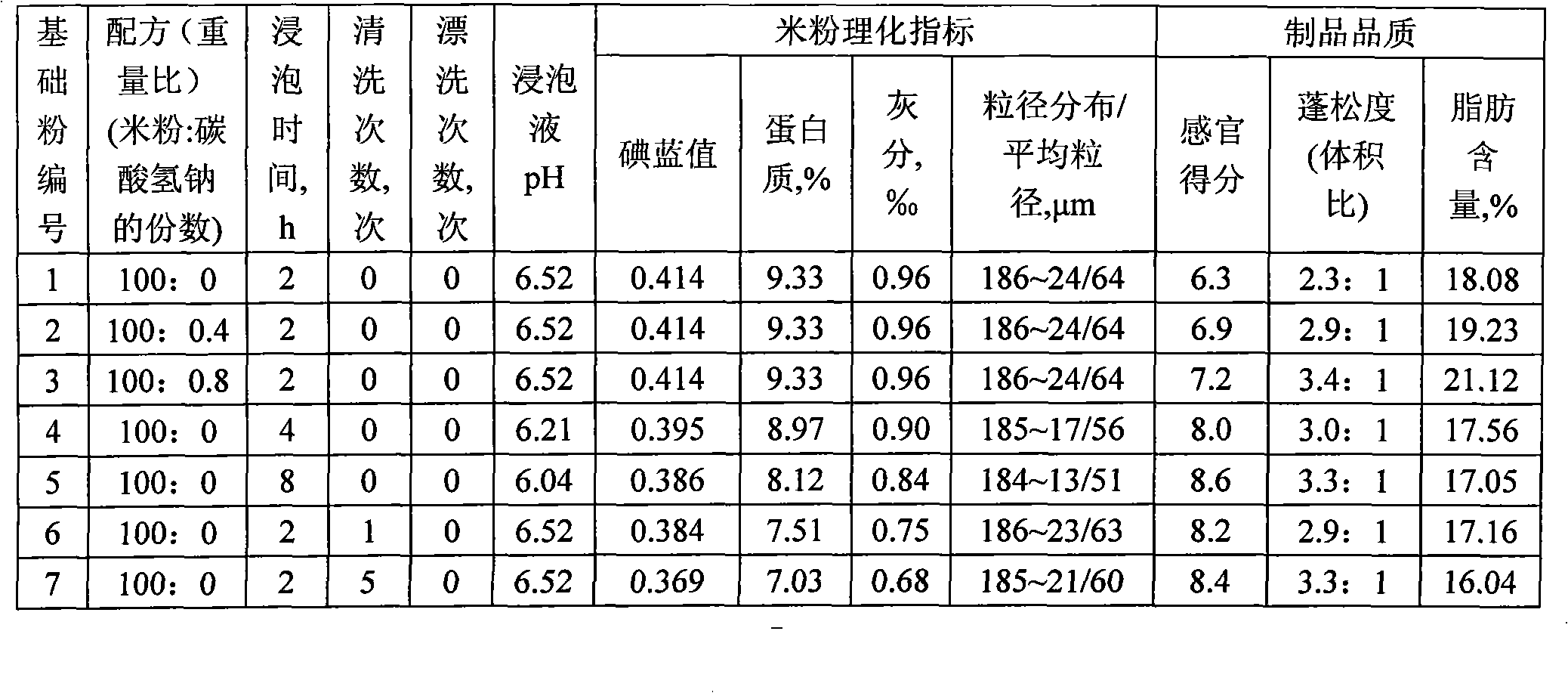

[0032] Embodiment 1: the preparation method of the food-specific flour (special flour for sesame balls) of fried food

[0033] A special food flour (special flour for sesame balls) suitable for making high-fluffy, low-oil-content fried rice products, the proportioning by weight is as follows:

[0034] Basic flour: rice flour: 100 parts, sodium bicarbonate: 0 parts,

[0035] The additional ingredients are white sugar powder: 25 parts and wheat flour: 25 parts;

[0036] Prepare as follows:

[0037] 1) Preparation of base powder: Clean commercially available rice, wash it with tap water for 1-2 times, soak it at room temperature at 20-35°C for 2-8 hours, wash it with tap water for 1-5 times, refine it, and use 1-3 volumes of rice Rinse with tap water twice as much and stir for 1 to 3 minutes, settle for 0.5 to 2 hours, remove the supernatant, repeat 1 to 3 times, filter with 200 to 600 mesh filter cloth, and dry at 40 to 60°C until the water content is 10 to 15%. , pulverized ...

Embodiment 2

[0039] The preparation method of the food-specific flour (special flour for sesame balls) of embodiment 2 fried food

[0040] The proportioning in parts by weight is as follows:

[0041] Basic flour: rice flour: 100 parts, sodium bicarbonate: 0.4 parts,

[0042] The additional ingredients are white sugar powder: 25 parts, wheat flour: 0 parts, according to the processing steps of Example 1 to obtain the special powder for sesame balls.

Embodiment 3

[0043] The preparation method of the food-specific flour (special flour for sesame balls) of embodiment 3 fried food

[0044] The proportioning in parts by weight is as follows:

[0045] Basic flour: rice flour: 100 parts, sodium bicarbonate: 0.8 parts,

[0046] Additional ingredients are white sugar powder: 25 parts, wheat flour: 10 parts, according to the processing steps of Example 1 to obtain the special powder for sesame balls.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com