Method for back washing electrolysis filler in catalytic iron by air and water

A technology that catalyzes iron and internal electrolysis. It is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of reducing the treatment effect, reducing the dissolution of iron ions, and affecting the stability of long-term operation. , to achieve the effect of simple method and good reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

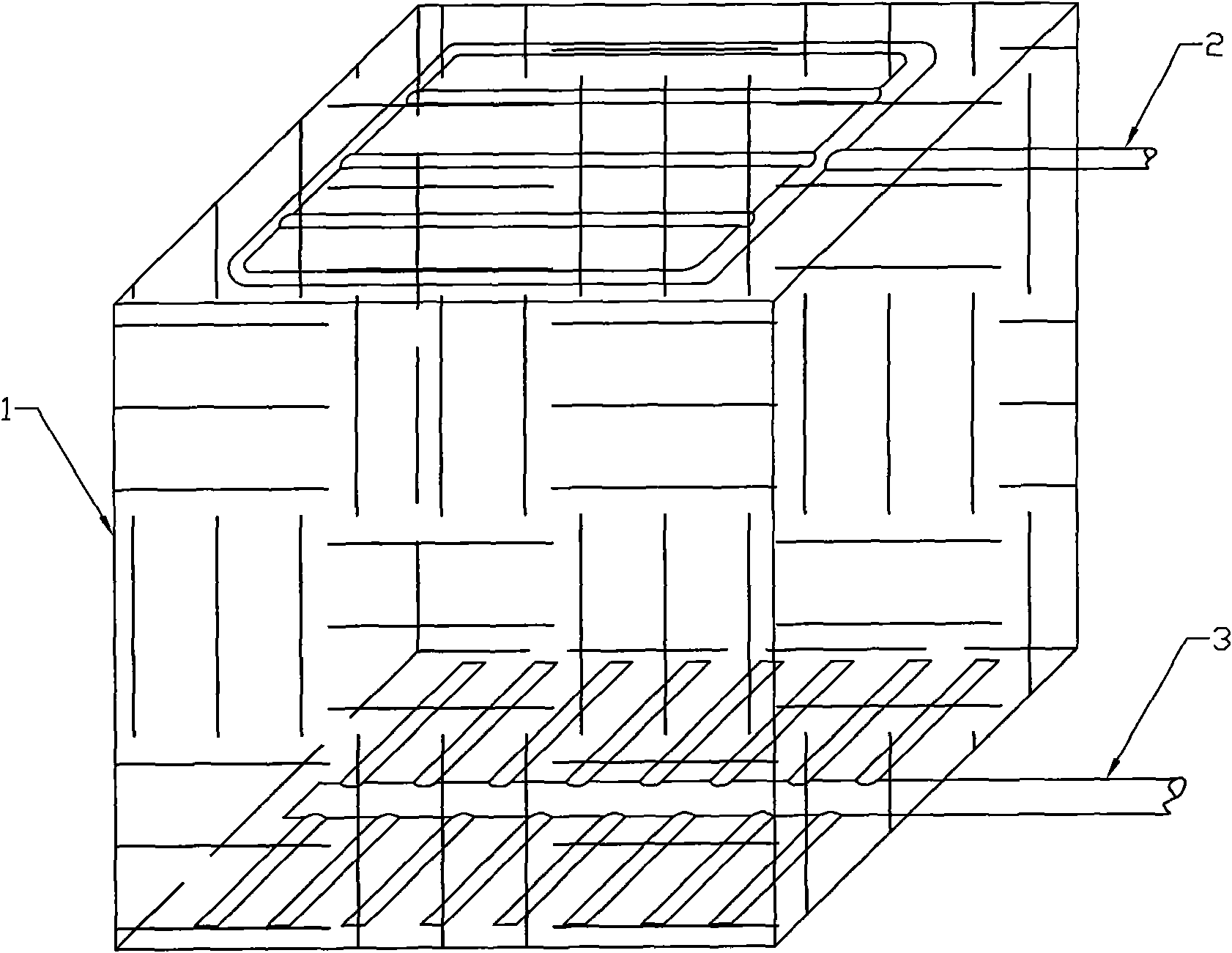

[0013] As shown in the figure, in the device used in the method of the present invention, the catalytic iron inner electrolytic packing 1 installed in the catalytic iron reactor is inserted with a recoil gas pipe 2 connected to a compressed air pipeline and a high-pressure water supply pipeline. Recoil water pipe 3; this system is a downward flow system, so the top surface of the packing is an outer plane facing the direction of water flow, and the recoil water pipe in the shape of a flat grid is 30-50mm away from the top surface of the packing; The shape of the recoil water pipe is arranged at a distance of 30-50mm from the bottom of the filler. If the reactor system is an advection system, the distribution plane of the recoil gas pipe should be set in the vertical direction.

[0014] Example: Pilot-scale catalytic iron and hydrolysis acidification coupling treatment system, the treatment scale is 1.5m 3 / h, the specification of the electrolytic filler in the catalytic iron is 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com