Method for preparing acetal by using glyoxal

A technology of glyoxal and acetal, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as energy loss and equipment cost increase, failure to meet energy saving and emission reduction, and complex reaction operations, etc., to achieve The effect of improving efficiency, increasing yield and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

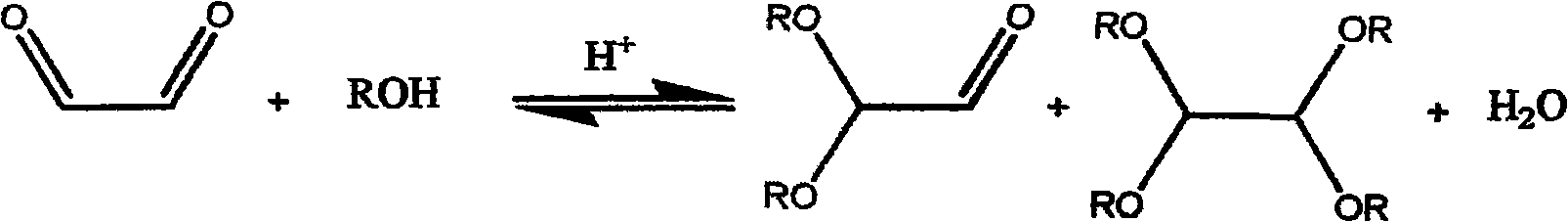

Image

Examples

Embodiment 1

[0020] Under the reduced pressure condition of 0.05-0.09MPa, 58g of 40 mass% glyoxal aqueous solution was concentrated, and the concentration temperature was 60-80°C, and the obtained 33.1g of 70 mass% glyoxal aqueous solution, 256g of methanol, 48g of methyl formate and 5.0g of 98 mass % sulfuric acid together and heated to reflux for 24 hours at a reflux temperature of 80°C. Wherein the raw material composition is methanol: methyl formate: glyoxal (molar ratio)=20:2:1. The product was analyzed by gas chromatography, and the crude yields of monoacetal and diacetal based on the glyoxal used were 55.93% and 24.86%.

Embodiment 2

[0022] Under the reduced pressure condition of 0.05~0.09MPa, 58g of 40 mass% glyoxal aqueous solution was concentrated, and the concentration temperature was 60~80°C, and the obtained 33.1g of 70 mass% glyoxal aqueous solution, 256g of formic acid, 240g of methyl formate and 5.0g of 98 mass % sulfuric acid together and heated to reflux for 20 hours at a reflux temperature of 90°C. Wherein the raw material composition is methanol:methyl formate:glyoxal (molar ratio)=20:10:1. The product was analyzed by gas chromatography, and the crude yields of monoacetal and diacetal based on the glyoxal used were 60.78% and 28.75%.

Embodiment 3

[0026] Under the condition of reduced pressure of 0.05-0.09MPa, 58g of 40 mass% glyoxal aqueous solution was concentrated, and the concentration temperature was 60-80°C. The obtained 33.1g of 70 mass% glyoxal aqueous solution, 192g of methanol, 48g of methyl formate and 10.9 g of methanesulfonate The acid was heated to reflux together for 24 hours, and the reflux temperature was 80°C. Wherein the raw material composition is methanol:methyl formate:glyoxal (molar ratio)=15:2:1. The product was analyzed by gas chromatography, and the crude yields of monoacetal and diacetal based on the glyoxal used were 45.55% and 25.76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com