Controlled buckling structures in semiconductor interconnects and nanomembranes for stretchable electronics

A technique for interconnecting structures and stretching components, which is applied to the structure of materials and devices, and the field of stretchable components of devices, which can solve problems such as research limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

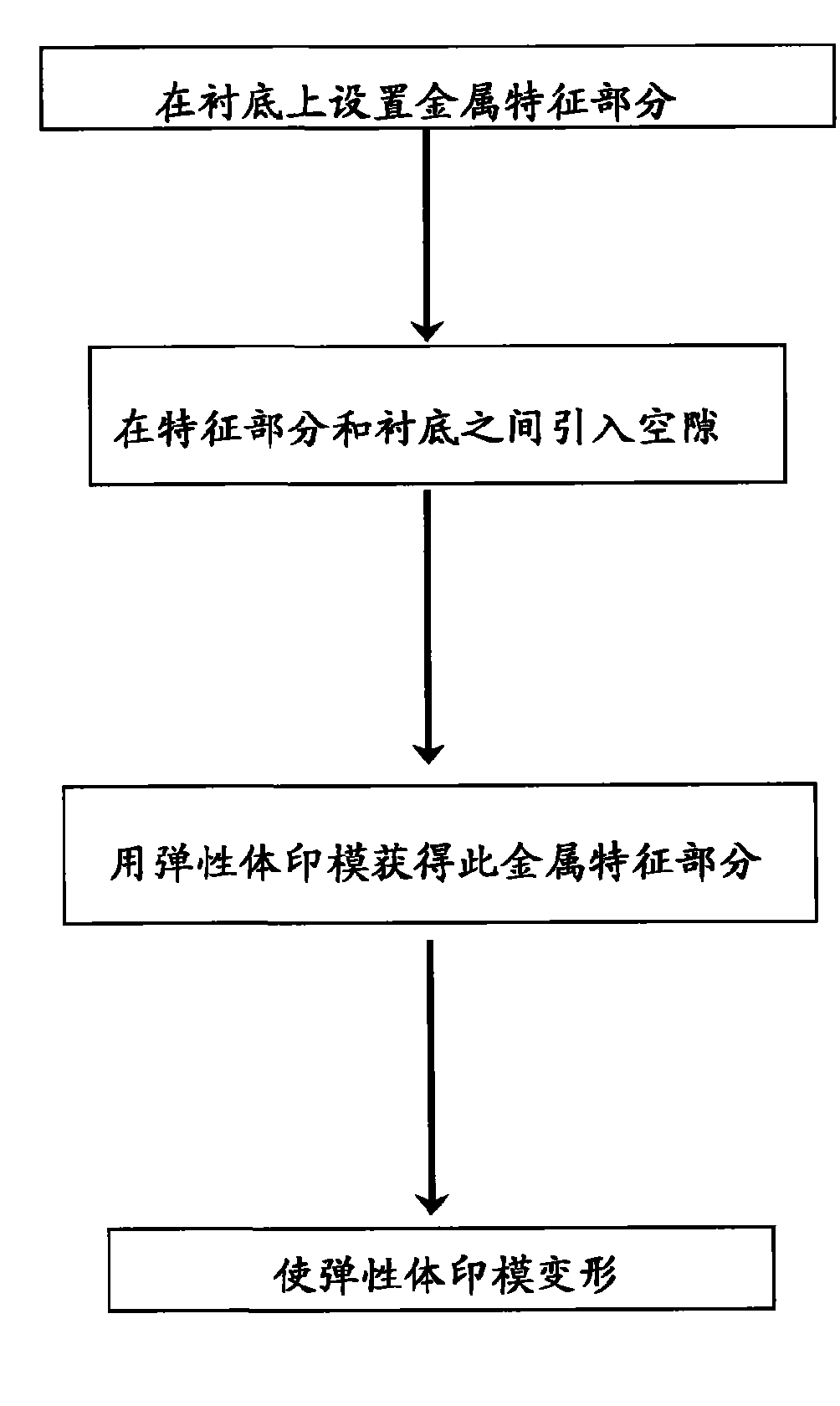

Method used

Image

Examples

Embodiment 1

[0186] Example 1: Controlled warp structure in semiconductor nanobelts and its application in stretchable electronic devices

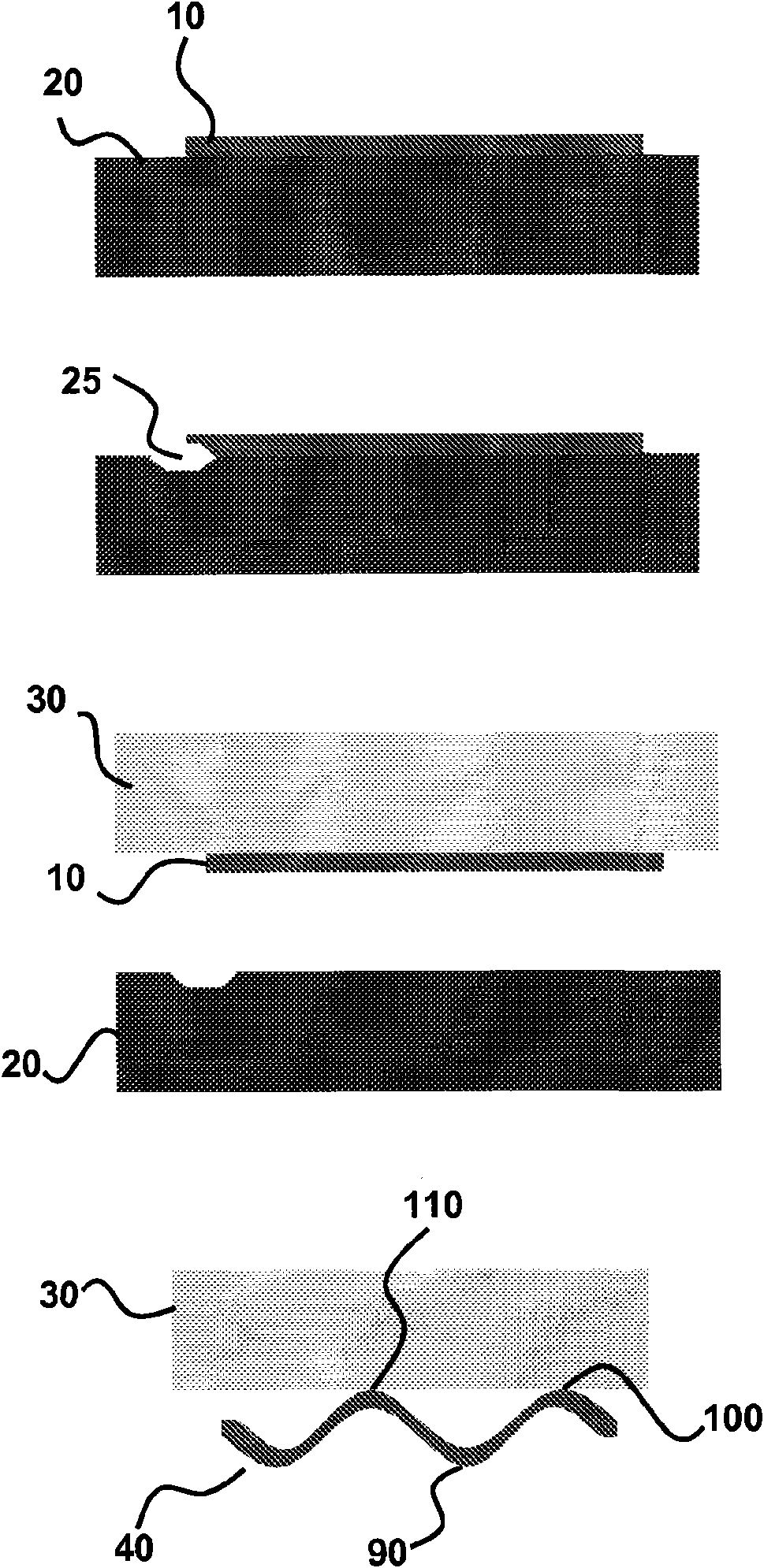

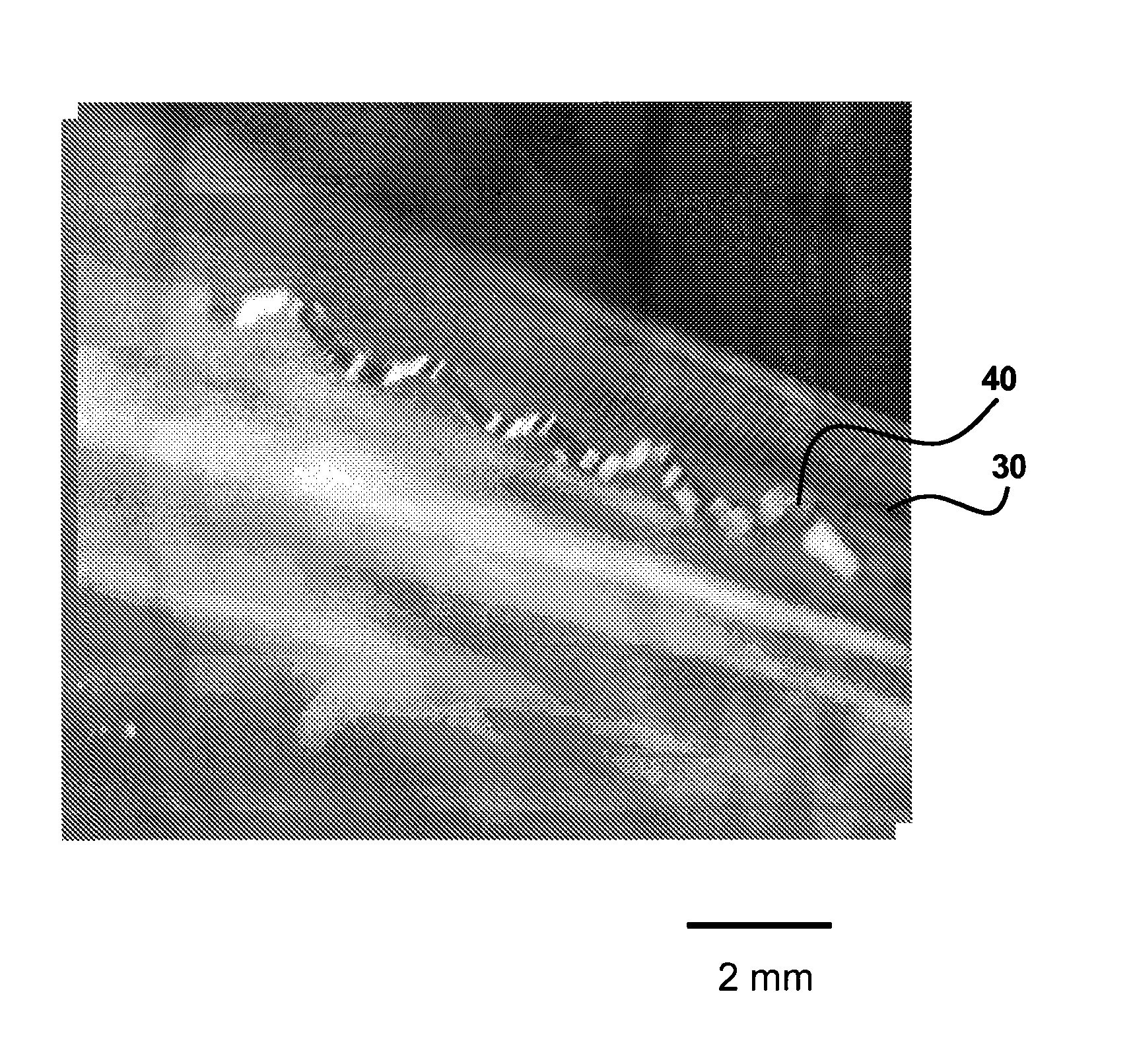

[0187] Important for almost all applications of these materials is the control over the composition, shape, spatial location and / or geometry of the semiconductor nanostructures. While methods exist for defining the material composition, diameter, length, and position of nanowires and nanoribbons, there are relatively few new ways to control their two- and three-dimensional (2D and 3D) structures. Presented here is a mechanistic strategy for creating certain types of 3D shapes that are otherwise difficult to generate in nanoribbons. This embodiment introduces the combined use of lithographically patterned surface chemistry methods to provide spatial control over the adhesive sites and elastic deformation of the support substrate, resulting in well-controlled localized displacement. Precisely designed warp geometries are created in this way in GaAs and ...

Embodiment 2

[0216] Example 2: transfer printing

[0217] Our technical approach uses certain concepts implemented in planar stamp-based printing methods as described previously. While these basic techniques provide an optimistic entry point, many fundamental new capabilities must be introduced to meet the challenges of HARDI (Hemispherical Array Detector Imaging) systems, as described below.

[0218] Figure 32 and 33 A general strategy related to transfer to curved surfaces is shown. The first set of steps ( Figure 32 ) involves the fabrication and manipulation of a thin, spherically curved elastomeric stamp designed to lift interconnected Si CMOS "microchips" off the flat surface of a wafer and then convert that geometry into a hemisphere. Elastomers such as polydimethylsiloxane (PDMS) are obtained by casting and curing liquid prepolymers against high-quality optical elements (i.e., matched convex and concave lenses) selected according to the required radius of curvature to form a ...

Embodiment 3

[0229] Example 3: Biaxially Stretchable "Waved" Silicon Nanofilms

[0230] This example introduces a biaxially stretchable form of single crystal silicon consisting of a two-dimensional warped or "wavy" silicon nanofilm on an elastomeric support. The fabrication process for these structures has been described and various aspects of their geometry in various directions and response to uniaxial and biaxial strain have been revealed. Analytical models of the mechanisms of these systems provide a framework for quantitatively understanding their behavior. These types of materials offer a route to high-performance electronics with fully two-dimensional stretchability.

[0231]Electronic devices exhibiting mechanical bendability are of interest for applications in information displays, X-ray imaging, optoelectronic devices, and other systems. Reversible stretchability is a different but technically challenging mechanical property that will allow devices to achieve functions that ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com