Hydrotreating method of high-acid and high-calcium crude oil

A technology for hydrogenation of residual oil and crude oil, applied in refining to remove heteroatoms, etc., can solve problems such as low metal content, achieve low hydrogen consumption, reduce hydrogen costs, and ensure long-term safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

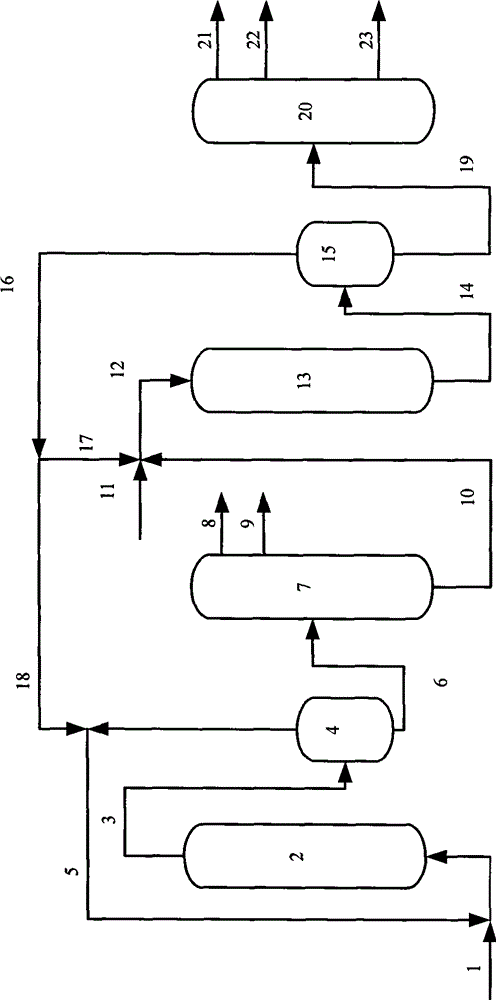

Method used

Image

Examples

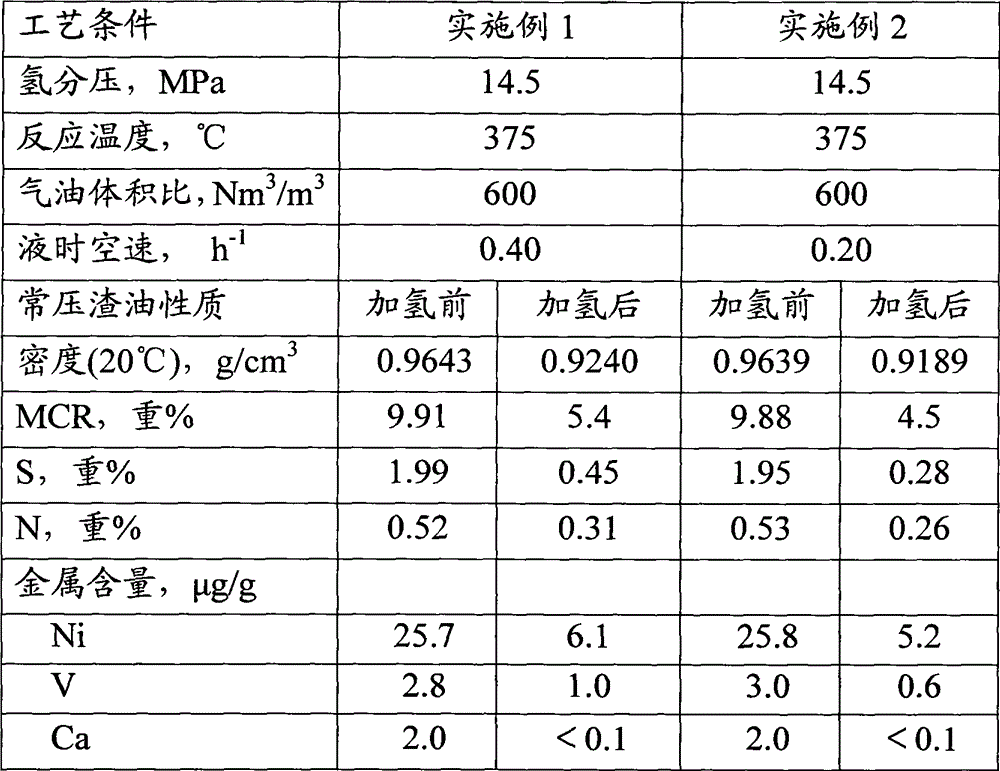

Embodiment 1

[0038] High-acid high-calcium crude oil and hydrogen are contacted with upflow hydrotreating catalyst RUF-1 in the crude oil hydrogenation reaction zone to carry out hydrotreating reaction, and the reaction products are cooled and separated to obtain hydrogen-rich gas and liquid products. The hydrogen-rich gas is recycled back to the upflow reactor, and the main properties of the obtained hydrogenated crude oil are shown in Table 3. The hydrogenated crude oil enters the atmospheric tower and is fractionated to obtain naphtha, diesel oil and atmospheric residue. The properties of the atmospheric residue are shown in Table 4. The atmospheric residue then enters the residue hydrogenation reaction zone and contacts with RG-10A, RG-10B, RDM-2 and RMS-1 in sequence. The properties of the hydrogenated oil are also listed in Table 4.

[0039] It can be seen from 3 that at a hydrogen partial pressure of 3.0MPa, a reaction temperature of 350°C, and a hydrogen-oil volume ratio of 200Nm ...

Embodiment 2

[0043] High-acid high-calcium crude oil and hydrogen are contacted with upflow hydrotreating catalyst RUF-1 in the crude oil hydrogenation reaction zone to carry out hydrotreating reaction, and the reaction products are cooled and separated to obtain hydrogen-rich gas and liquid products. The hydrogen-rich gas is recycled back to the upflow reactor, and the main properties of the obtained hydrogenated crude oil are shown in Table 3. The hydrogenated crude oil enters the atmospheric tower and is fractionated to obtain naphtha, diesel oil and atmospheric residue. The properties of the atmospheric residue are shown in Table 4. The atmospheric residue then enters the residue hydrogenation reaction zone and contacts with RG-10A, RG-10B, RDM-2 and RMS-1 in sequence. The properties of the hydrogenated oil are also listed in Table 4.

[0044] It can be seen from 3 that at a hydrogen partial pressure of 5.0MPa, a reaction temperature of 350°C, and a hydrogen-oil volume ratio of 200Nm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com