Microfluidic chip for integrated solid phase micro extraction and detection method

A microfluidic chip and extraction technology are applied in sample analysis and detection. The design of microfluidic chip and its application in the field of analysis and detection can solve the problems of the chip can no longer be used, the commercial fiber is expensive, and there are not many types of coatings. , to achieve the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

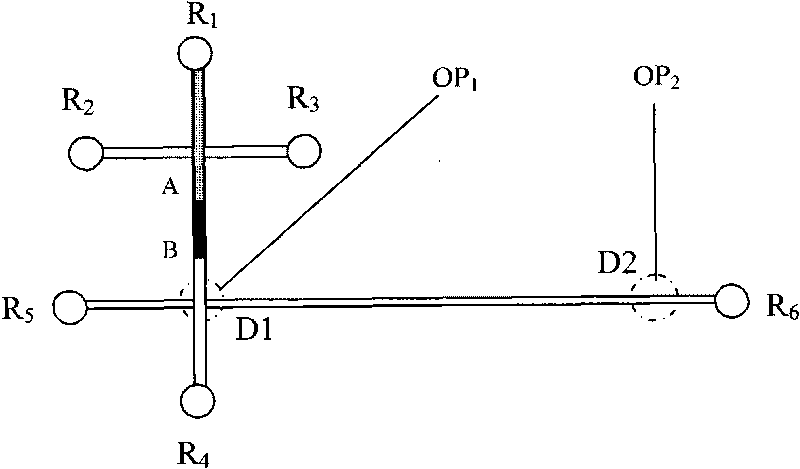

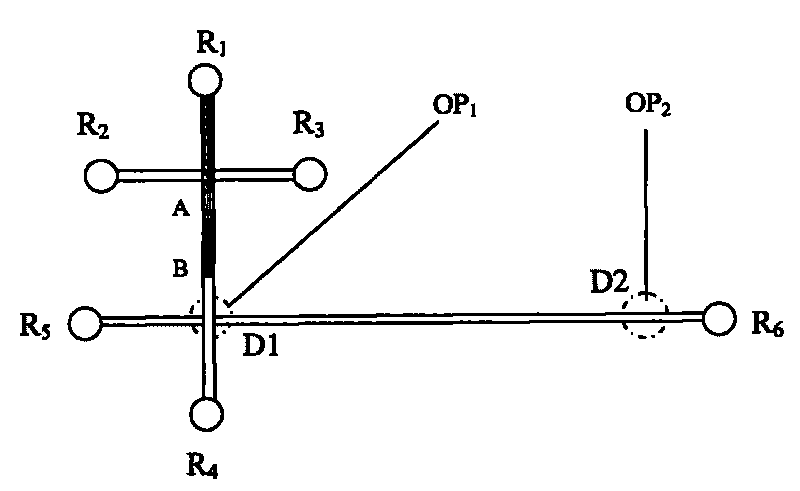

[0018] A characteristic of the present invention is that the porous microsphere coated with the organic polymer adsorption layer is introduced into the extraction channel of the microfluidic chip as the stationary phase of the solid phase microextraction. The advantage of this method is that, according to the type and nature of the target analyte, the adsorption material that can better absorb the target analyte can be selected and coated on the inorganic microbeads, which improves the flexibility and selectivity of chip solid phase microextraction. Moreover, when the extraction efficiency of the stationary phase deteriorates, the stationary phase can be easily replaced without discarding the entire chip, which increases the versatility of the chip. In addition, the preparation of the stationary phase is simple. It only needs to fill the solid-phase microextraction channel with the microspheres coated with the adsorption layer, without complicated in-channel coating or in-situ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com