Method for improving sweetness of stevia sugar

A technology of stevioside and sweetness, which is applied in the field of food additives and sweeteners, and can solve the problems of small sample size and difficult industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Preparation of bacterial solution:

[0036] Bacillus megaterium J2 (Bacillus megaterium J2) CCTCC NO: M209201 was cultured in a conventional broth liquid medium at 37° C. and 220 rpm for 48 hours to obtain the bacterial liquid.

[0037] Preparation of bacterial powder:

[0038] It includes fermentation culture of bacteria, separation of fermentation liquid, emulsification of bacteria slime and vacuum freeze drying of emulsion. That is, Bacillus megaterium J2 (Bacillus megaterium J2) CCTCC NO: M209201 was cultured in the above liquid based on the bacteria liquid obtained after 48 hours of culture, centrifuged at 8000rpm and 5min to collect the bacteria to obtain the sludge, and the sludge was vacuum-frozen under the condition of a vacuum of 1-5pa After drying for 30 hours, the bacteria powder is obtained.

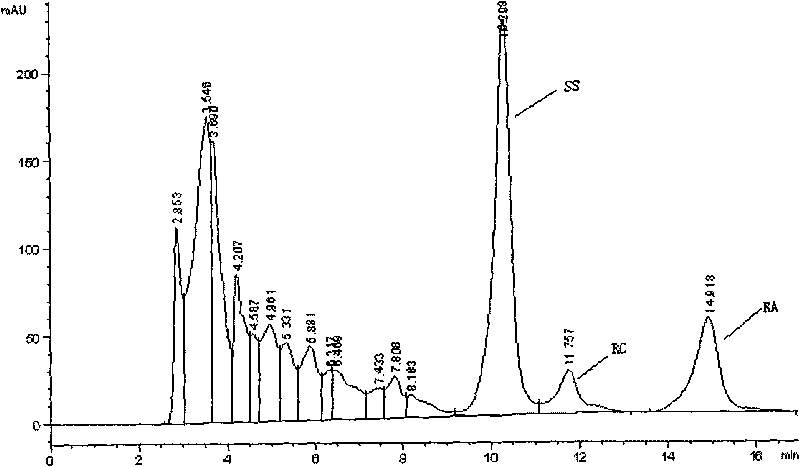

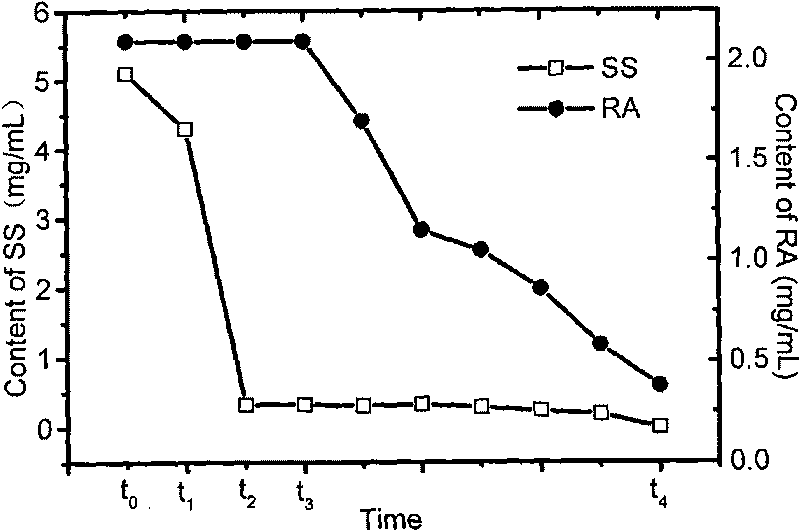

[0039] Degradation characteristics of SS and RA by degrading bacteria:

[0040] Bacillus megaterium J2 (Bacillus megaterium J2) CCTCC NO: M209201 is cultivated for...

Embodiment 1

[0047] 0.5% (W / W), pH 5.0 stevioside solution (RA purity is about 85%), sterilized and cooled, then added 5% (W / W) Bacillus megaterium J2CCTCC NO: M209201 bacterial solution, cultured at 37°C for 72h, after After conversion, SS was mostly degraded, and RA content remained unchanged. After the transformation, the cells were removed by centrifugation at 5000rpm, and the supernatant was removed by flocculation and sedimentation, adsorbed and separated by macroporous resin, and the purified liquid was crystallized to obtain RA with a purity of about 98%.

Embodiment 2

[0049] 0.01% (W / W), pH 4.5 stevioside solution (RA purity is about 75%), add 2% (W / W) bacteria powder of Bacillus megaterium J2CCTCC NO: M209201, after culturing at 37°C for 36 hours, according to the conventional RA with a purity of about 90% was obtained by separation and purification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com