Preparation method of polylactic acid/chitosan/carbon fiber porous supports

A porous scaffold and carbon fiber technology, applied in medical science, prosthesis, etc., achieves high academic value and use value, is conducive to adhesion, and has the effect of large internal surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

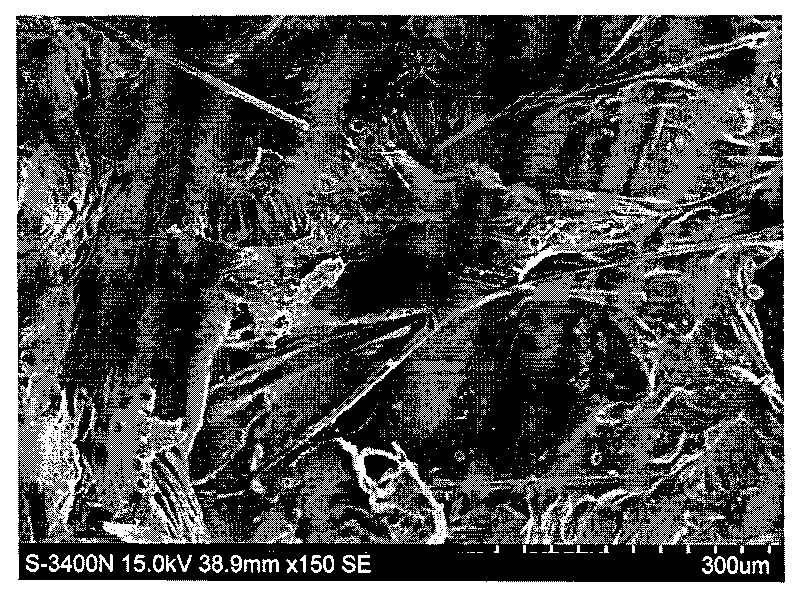

Image

Examples

Embodiment 1

[0024] 1) Weigh 6.0001g of methylcellulose and add it to a flask filled with 400ml of deionized water, add about 1.2000g of carbon fiber, stir and disperse on a magnetic stirrer for 60min, filter the carbon fiber on a 200-mesh sieve and dry it for later use; weigh Dissolve 4.4001g of chitosan in 20mL of deionized water and set aside; weigh 7.9996g of polylactic acid and dissolve in 40mL of tetrahydrofuran for use.

[0025]2) Weigh 0.0100g of carbon fiber into 40mL of polylactic acid solution, and ultrasonically mix in an ultrasonic oscillator for 1.5h; add 5mL of chitosan solution, stir gently with a magnetic stirring speed of 100r / min for 0.5h, and then oscillate with ultrasonic waves for 4h ,; Pour the uniformly mixed ternary mixture into the bracket mold, put it into the freeze dryer and freeze it quickly to -55±2°C, freeze it at this temperature for 6 hours, and then keep the freezing temperature under vacuum at 15.6KPa to vacuumize 3h, and finally 5°C low-temperature dryi...

Embodiment 2

[0027] 1) Weigh 2.9981g of methylcellulose and add it to a flask filled with 200ml of deionized water, add about 0.4500g of carbon fiber, stir and disperse on a magnetic stirrer for 40min, filter the carbon fiber on a 200-mesh sieve and dry it for later use; weigh Dissolve 1.9998g chitosan in 10mL deionized water and set aside; weigh 6.0002g polylactic acid and dissolve it in 30mL carbon trichloride and set aside.

[0028] 2) Weigh 0.0080g carbon fiber and put it into 30mL polylactic acid solution, and ultrasonically mix it in an ultrasonic oscillator for 2h; add 3mL chitosan solution, mix and stir gently with a magnetic stirring speed of 150r / min for 1h, and then oscillate with ultrasonic wave for 3.5h, ; Pour the well-mixed ternary mixture into the bracket mold, put it into the freeze dryer and freeze it quickly to -58±2°C, freeze it at this temperature for 7.5 hours, and then keep the freezing temperature under vacuum at 17.0KPa to vacuumize After 2.5 hours, dry at 5°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com