Continuous production process for polyurethane thermal insulation boards

A technology of thermal insulation board and production process, applied in thermal insulation, manufacturing tools, manipulators, etc., can solve the problems of low degree of automation, small production volume, and difficult quality control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

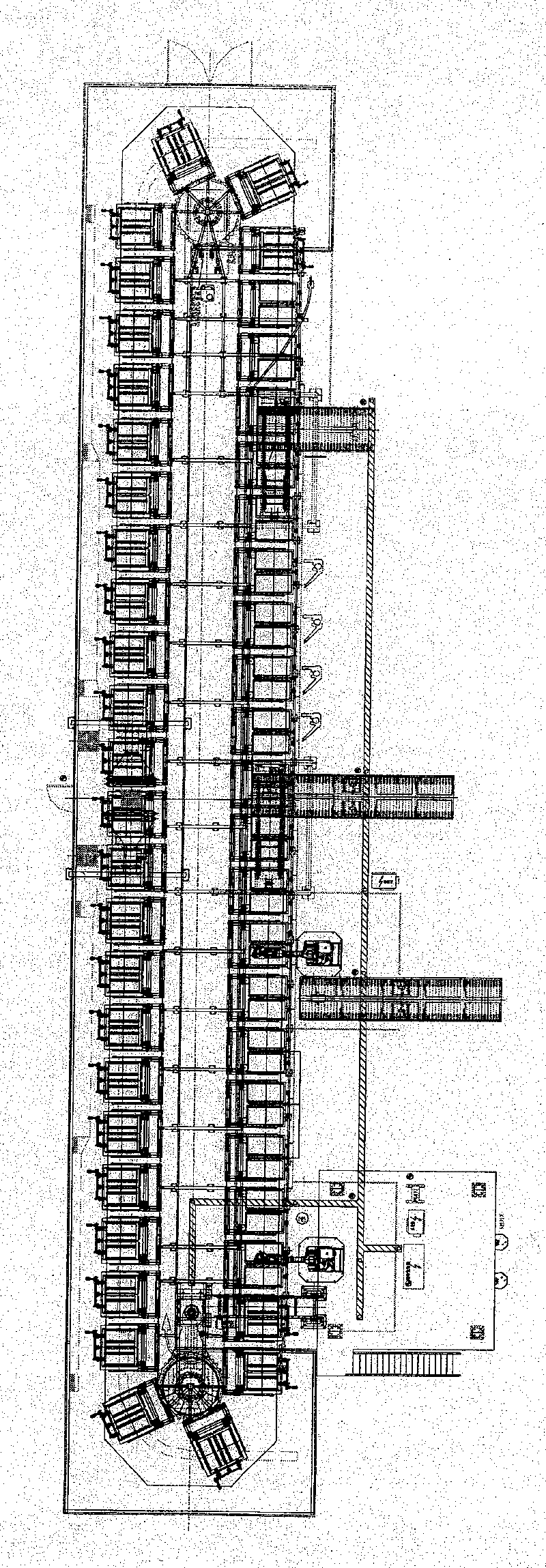

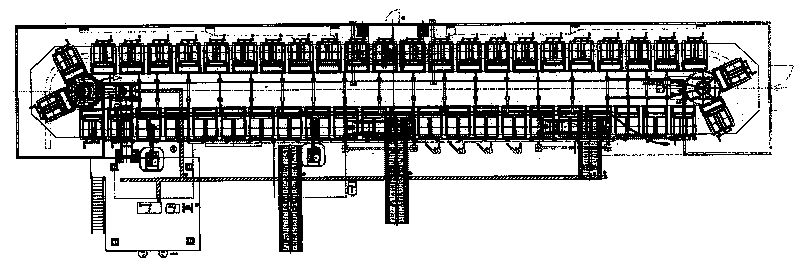

[0005] The present invention is described in further detail now in conjunction with accompanying drawing. refer to figure 1 , the present invention adopts the energy-saving insulation board production line with an annual output of 2.5 million m2, adopts multi-station (40-50) horizontal ground ring structure layout, and drives the whole mold conveying line along the chain driven by the geared motor with brake through the sprocket box. Circular movement, the mold base adopts mechanical opening and closing and airbag mold locking, and its structure meets the foaming of composite boards whose upper and lower layers are cement fiber boards and the core material is polyurethane rigid foam. The size of the mold base can ensure that one mold can foam two boards at the same time (board length×board width=1200mm×600mm). There is also a product curing heating oven on the line body to ensure the product curing temperature. Two robots are equipped on the production line, one of which is O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com