Purifying method of N-methylpyrrolidone

A technology for methylpyrrolidone and purification methods, applied in chemical instruments and methods, separation methods, organic chemistry, etc., can solve the problems of low yield, unstable yield, easy moisture absorption, etc., and achieve simple process route and low manufacturing cost Low, consistent quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

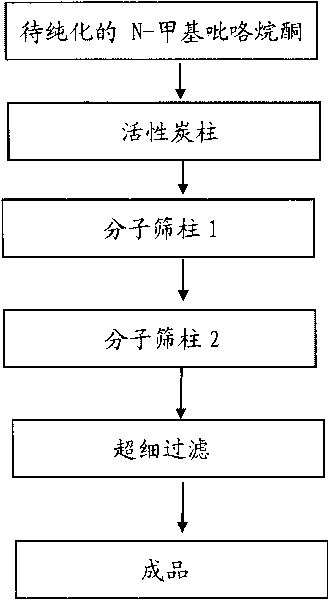

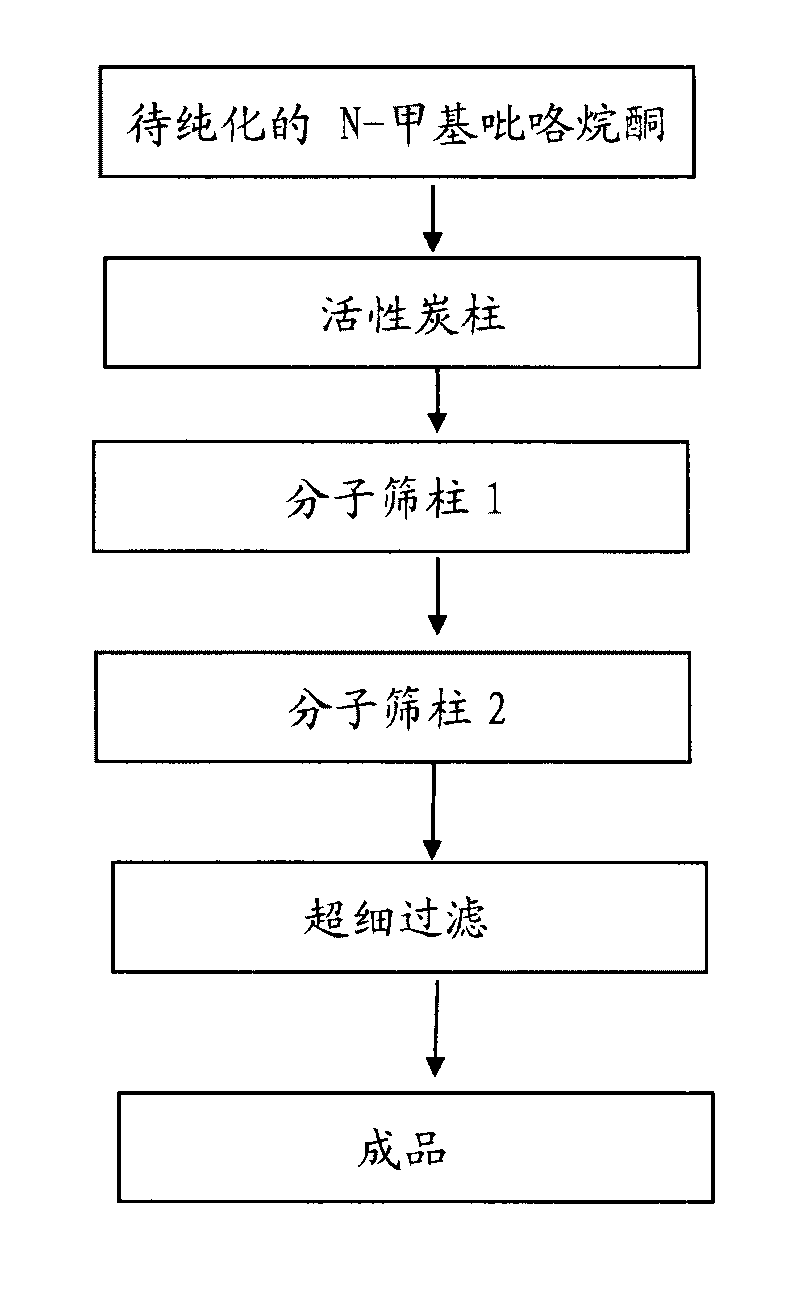

Image

Examples

Embodiment 1

[0015] The N-methylpyrrolidone to be purified is passed through a specification of Activated carbon column, activated carbon particles are strip-shaped particles, adsorbing methylamine to make the content below 0.005%; and then passing the specification as Two series-connected molecular sieve columns of model 3A absorb moisture to reduce the moisture to less than 0.01%; finally, the solid particles are removed by ultra-fine filtration, and enter the finished product bottle in a dry environment, and the yield of the finished product is 95%. Wherein, the flow rate of N-methylpyrrolidone in the purification process is 0.4 liters / hour.

Embodiment 2

[0017] The N-methylpyrrolidone to be purified is passed through a specification of Activated carbon column, activated carbon particles are Spherical or strips, absorbing methylamine to make the content below 0.005%; then the specification is Two series-connected molecular sieve columns of model 4A absorb water to reduce the water to less than 0.01%; finally, the solid particles are removed by ultra-fine filtration, and enter the finished product bottle in a dry environment. The yield of the finished product is 96%. Wherein, the flow rate of N-methylpyrrolidone during the purification process is 0.5 liter / hour.

Embodiment 3

[0019] The N-methylpyrrolidone to be purified is passed through a specification of Activated carbon column, the diameter of activated carbon particles is 2mm, absorbing methylamine to make the content below 0.005%; and then the specification is Two series-connected molecular sieve columns of model 5A absorb moisture to reduce the moisture to less than 0.01%; finally, the solid particles are removed by ultra-fine filtration, and enter the finished product bottle in a dry environment, and the yield of the finished product is 97%. Wherein, the flow rate of N-methylpyrrolidone in the purification process is 0.6 liters / hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com