Transparent extended p-n heterojunction thin film and preparation method thereof

An epitaxial thin film and heterojunction technology, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. The effect of optical transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

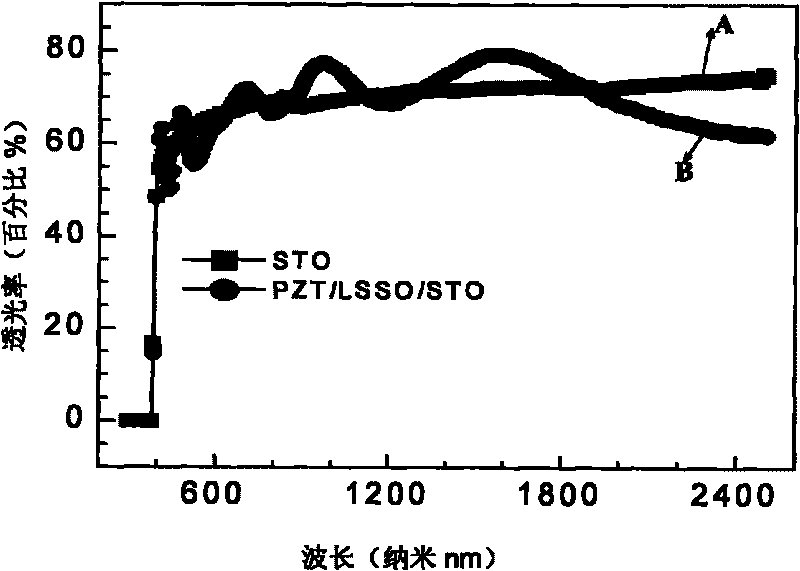

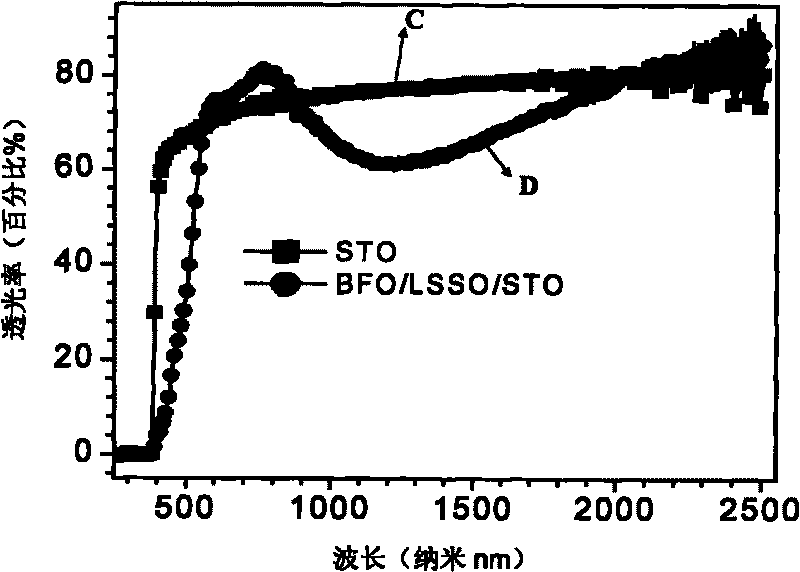

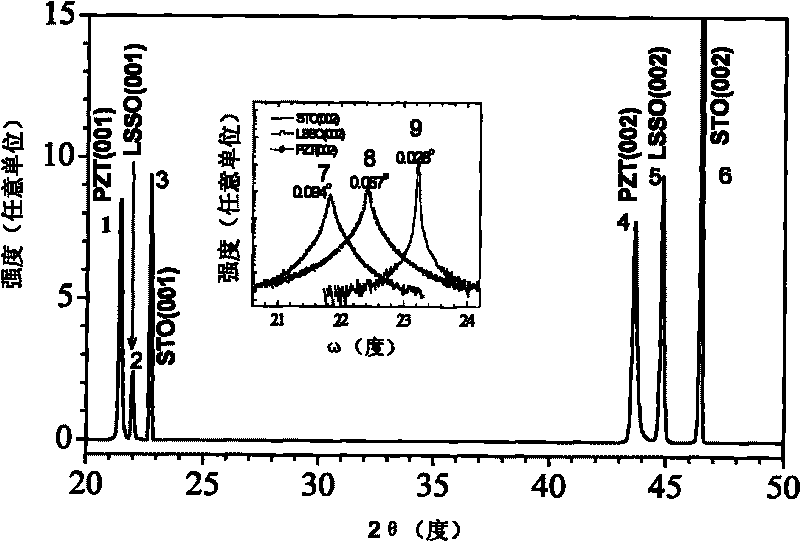

[0044] Example 1. Preparation of p-n heterojunction thin film with PZT / LSSO / STO structure

[0045] 1) The pulsed laser deposition method is used to deposit on the STO single crystal substrate under the conditions of laser energy of 190mJ, laser frequency of 5Hz, deposition temperature of 690°C, and oxygen pressure of 20pa to obtain LSSO epitaxy with a deposition thickness of 100nm film; the La x Sr 1-x SnO 3 In the epitaxial film, x=0.03.

[0046] Among them, the LSSO target material required for the preparation of LSSO epitaxial film is prepared according to the following method: strontium titanate SrCO 3 (purity ≥ 99%) powder, lanthanum oxide La 2 o 3 (purity ≥ 99.99%, lanthanum oxide is prone to deliquescence in the air, in order to ensure accurate quality, it should be dried in a high-temperature furnace above 500°C for 2 hours before use) powder and tin oxide SnO 2 (purity ≥ 99.8%) powder according to La 0.03 Sr 0.97 SnO 3 The chemical molar ratio is configured, ...

Embodiment 2

[0058] Example 2, Preparation of p-n heterojunction thin film with PZT / LSSO / STO structure

[0059] 1) The pulsed laser deposition method is used to deposit on the STO single crystal substrate under the conditions of laser energy of 170mJ, laser frequency of 8Hz, deposition temperature of 650°C, and oxygen pressure of 15pa to obtain LSSO epitaxy with a deposition thickness of 100nm film; the La x Sr 1-x SnO 3 In the epitaxial film, x=0.05.

[0060] Among them, the LSSO target material required for the preparation of LSSO epitaxial film is prepared according to the following method: strontium titanate SrCO 3 (purity ≥ 99%) powder, lanthanum oxide La 2 o 3 (purity ≥ 99.99%, lanthanum oxide is prone to deliquescence in the air, in order to ensure accurate quality, it should be dried in a high-temperature furnace above 500°C for 2 hours before use) powder and tin oxide SnO 2 (purity ≥ 99.8%) powder according to La 0.05 Sr 0.95 SnO 3 The chemical molar ratio is configured, ...

Embodiment 3

[0072] Example 3. Preparation of p-n heterojunction thin film with PZT / LSSO / STO structure

[0073] 1) The pulsed laser deposition method is used to deposit on the STO single crystal substrate under the conditions of laser energy of 210mJ, laser frequency of 10Hz, deposition temperature of 750°C, and oxygen pressure of 30pa to obtain LSSO epitaxy with a deposition thickness of 150nm. film; the La x Sr 1-x SnO 3 In the epitaxial film, x=0.07.

[0074] Among them, the LSSO target material required for the preparation of LSSO epitaxial film is prepared according to the following method: strontium titanate SrCO 3 (purity ≥ 99%) powder, lanthanum oxide La 2 o 3 (purity ≥ 99.99%, lanthanum oxide is prone to deliquescence in the air, in order to ensure accurate quality, it should be dried in a high-temperature furnace above 500°C for 2 hours before use) powder and tin oxide SnO 2 (purity ≥ 99.8%) powder according to La 0.07 Sr 0.93 SnO 3The chemical molar ratio is configured,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com