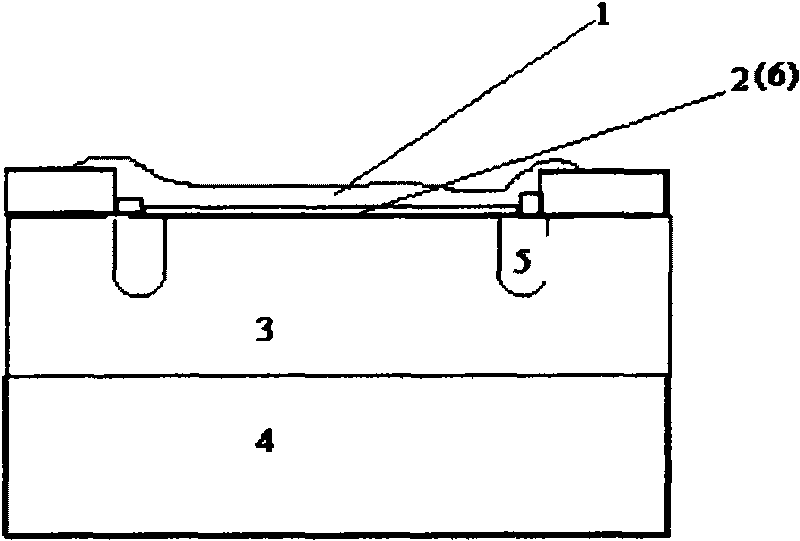

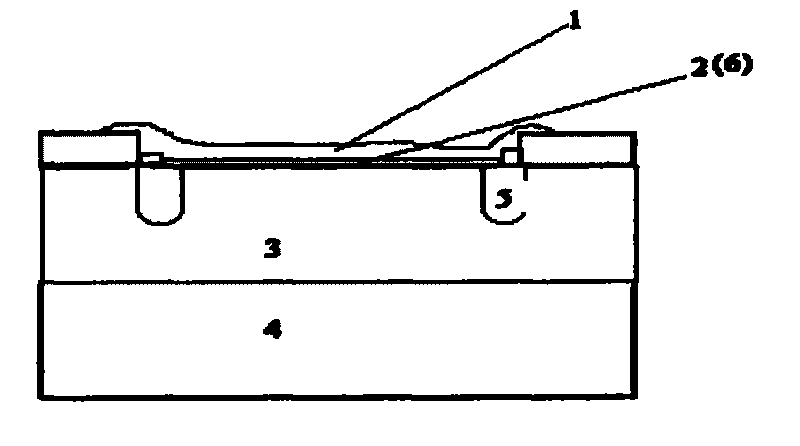

Schottky barrier diode and preparation method thereof

A Schottky potential and diode technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of increasing production management complexity, complex process, and high equipment requirements, improving electrical efficiency and reducing potential barriers. Highly effective, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A thin oxide layer is grown between the silicon epitaxial wafer and the metal, the thickness of the oxide layer is Then sputter or evaporate the metal, and clean the thin oxide layer with a mixed solution of ammonia, hydrogen peroxide and water at a ratio of 1:2:8 at 75°C for 30 minutes, and the alloy forms a silicide as a barrier layer.

[0033] The obtained diode barrier height is 0.629, and the oxide layer thickness is The forward voltage drop is 0.541V.

Embodiment 2

[0035] A thin oxide layer is grown between the silicon epitaxial wafer and the metal, the thickness of the oxide layer is Then sputter or evaporate the metal, and clean the thin oxide layer with a mixed solution of ammonia, hydrogen peroxide and water at a ratio of 1:2:8 at 75°C for 20 minutes, and the alloy forms a silicide as a barrier layer.

[0036] The obtained diode barrier height is 0.624v, and the oxide layer thickness is The forward voltage drop is 0.543V.

Embodiment 3

[0038] A thin oxide layer is grown between the silicon epitaxial wafer and the metal, the thickness of the oxide layer is Then sputter or evaporate the metal, and clean the thin oxide layer with a mixed solution of ammonia, hydrogen peroxide and water at a ratio of 1:2:8 at 75°C for 10 minutes, and the alloy forms a silicide as a barrier layer.

[0039] The barrier height of the obtained diode is 0.655v, and the thickness of the oxide layer is The forward voltage drop is 0.580V. The oxide layer grown in this way is easy to operate, low in cost, and can remove surface particles to improve the yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com