Dry-type compound aqueous paper/plastic laminating emulsion adhesive and preparation method thereof

A dry compounding and laminating adhesive technology is applied in the field of dry compounding water-based paper-plastic laminating adhesive and its preparation, which can solve the problems of poor ink wettability, easy yellowing and peeling, poor water resistance, and poor frost resistance. , to achieve the effect of improving the final peel strength, enhancing stability and small strength difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The first embodiment provides a dry composite water-based paper-plastic laminating glue, which is composed of the following raw materials by weight percentage:

[0035] Vinyl acetate-ethylene copolymer 5~20%

[0036] Acrylic monomer 25~40%

[0037] Emulsifier accounts for 1-3% of the total weight of acrylic acid monomer

[0038] Polymerization initiator accounts for 0.4-0.8% of the total weight of acrylic acid monomers

[0039] Post-elimination initiator accounts for 0.2-0.6% of the total weight of acrylic acid monomers

[0040] Buffering agent accounts for 0.1-1% of the total weight of acrylic acid monomers

[0041] Wetting agent 1~3%

[0042] Defoamer 1~3%

[0043] Preservatives 0.1~1%

[0044] Ammonia 1~3%

[0045] The rest is deionized water;

[0046] The above-mentioned acrylic monomer adopts any one of acrylic acid (AA) or methacrylic acid (MAA) and 1 to 2 kinds of acrylate soft monomers; among them, acrylic acid (AA) or methacrylic acid (MAA) accounts for...

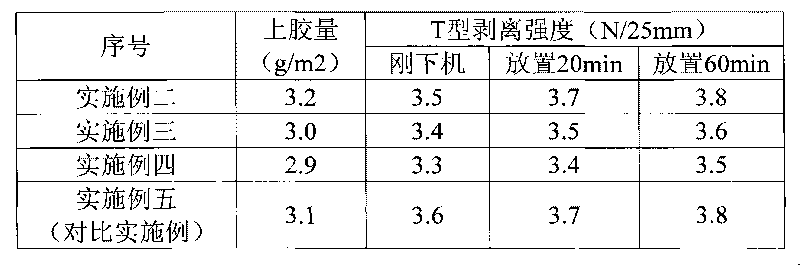

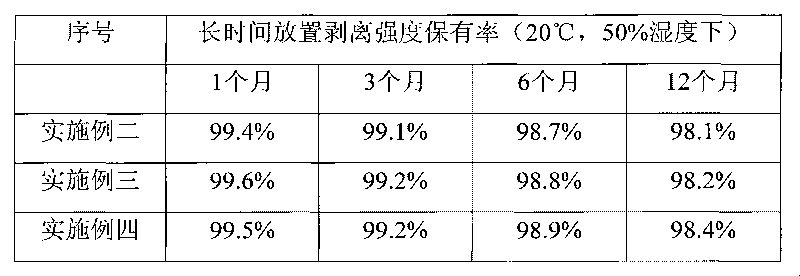

Embodiment 2

[0061] The second embodiment provides a dry composite water-based paper-plastic laminating adhesive. The formula (parts by weight) of each component of the laminating adhesive is as follows:

[0062] Part A:

[0063] Deionized water 210

[0064] CO-436 (Rhodia company product) 0.72

[0065] NP-10 (DOW company product) 0.45

[0066] Acrylic (AA) 95

[0067] Ethyl Acrylate (EA) 48

[0068] Butyl Acrylate (BA) 218

[0069] Sodium bicarbonate solution (dissolved into 5wt% solution with deionized water) 50

[0070] Part B:

[0071] Deionized water 180

[0072] CO-436 (Rhodia company product) 0.08

[0073] NP-10 (DOW company product) 0.05

[0074] VAE emulsion (BJ-705, product of Beijing Organic Chemical Factory) 190

[0075] Part C

[0076] Ammonium persulfate solution (dissolved into 4wt% solution with deionized water) 55

[0077] Part D

[0078] tert-butyl hydroperoxide (diluted with 4 times the weight of deionized water) 2

[0079] Hanging white block (dissolved wi...

Embodiment 3

[0091] The second embodiment provides a dry composite water-based paper-plastic laminating adhesive. The formula (parts by weight) of each component of the laminating adhesive is as follows:

[0092] Part A:

[0093] Deionized water 200

[0094] CO-436 (Rhodia company product) 0.64

[0095] NP-10 (DOW company product) 0.56

[0096] Methacrylic acid (MAA) 76

[0097] Ethyl Acrylate (EA) 62

[0098] Isooctyl Acrylate (EHA) 186

[0099] Ammonium bicarbonate solution (dissolved into a 5wt% solution with deionized water) 48

[0100] Part B:

[0101] Deionized water 240

[0102] CO-436 (Rhodia company product) 0.16

[0103] NP-10 (DOW company product) 0.14

[0104] VAE emulsion (BJ-707, product of Beijing Organic Chemical Factory) 160

[0105] Part C

[0106] Ammonium persulfate solution (dissolved into 4wt% solution with deionized water) 52

[0107] Part D

[0108] tert-butyl hydroperoxide (diluted with 4 times the weight of deionized water) 2

[0109] Hanging white b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com