Method for producing microorganism culture media nitrogen source from waste organisms

A microbial culture medium and organic matter technology, applied in fungi, bacteria and other directions, can solve the problems of low calorific value of biological organic matter, limited application prospects, accumulation of antibiotics, etc., and achieve the effects of stable physical and chemical properties, wide source of raw materials, and simple process route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

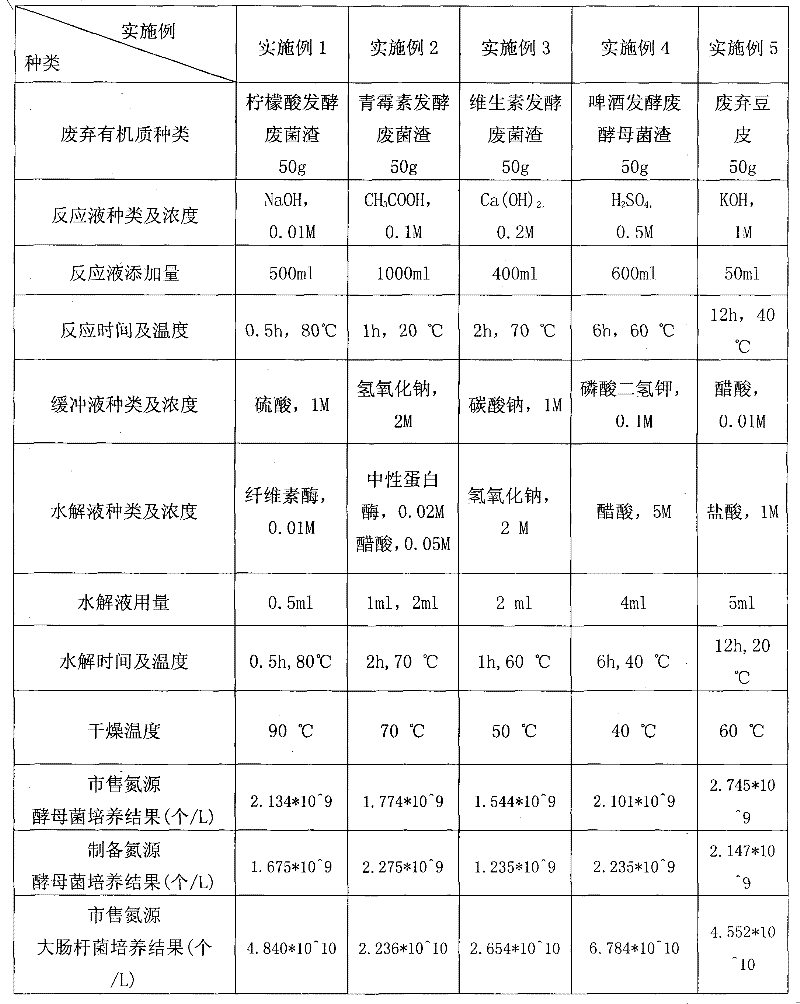

[0024] Add 500ml of 0.01M NaOH to 50g of wet citric acid waste mycelia, heat the reaction at 80°C for 0.5h, filter, remove the precipitate, add 0.1ml of 1MH to the protein-rich phase 2 SO 4 Buffer, adjust the pH to 4, add 0.5ml, 0.01M cellulase, and hydrolyze at 80°C for 0.5 hours, and the highest absorbance is detected, that is, the reaction is complete. The reaction solution obtained above is hydrolyzed, then decolorized and concentrated, dried in an oven at 90°C, and crushed into powder after drying, which is the product.

[0025] After the product is processed, it is used for microbial culture, and the culture results are as follows:

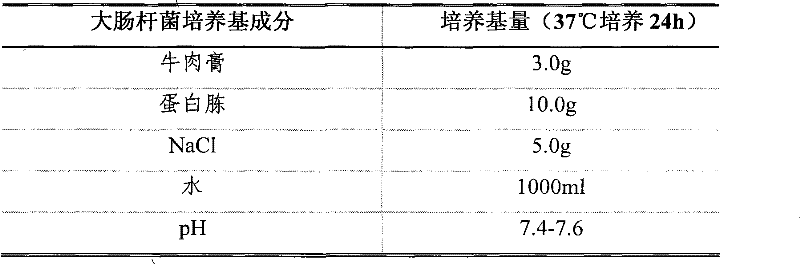

[0026] The product was used for the cultivation of Escherichia coli, and the bacterial liquid culture medium (Table 1) was used to replace the beef extract in Table 1 as a nitrogen source, and it was cultivated at 37°C for 24 hours, and a good cultivation effect was obtained.

[0027] The product was used for the cultivation of Escherichia...

Embodiment 2

[0032] The operating methods of embodiment 2, embodiment 3 and embodiment 4 are the same as embodiment 1, and the operating parameters are shown in table 1.

Embodiment 5

[0034] Add 50ml of 1M KOH to 50g of waste bean curd, heat and react at 40°C for 12h, filter, remove the precipitate, add a certain amount of 0.01M acetic acid to the protein-rich phase for buffering, adjust the pH to 10, and then add 5ml, 1M Hydrochloric acid is hydrolyzed at a temperature of 20°C for 12 hours, and the highest absorbance is detected through detection, that is, the reaction is complete. The reaction solution obtained above is hydrolyzed, then decolorized and concentrated, dried in an oven at 60°C, and crushed into powder after drying, which is the product.

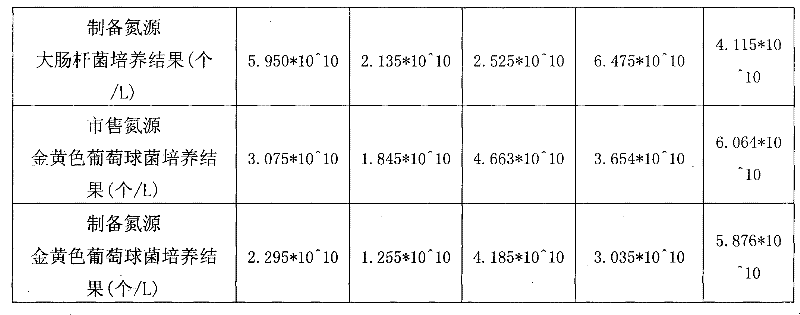

[0035]After the product is processed, it is used for microbial culture, and the culture results are as follows:

[0036] The product was used for the cultivation of Escherichia coli, using the bacterial liquid culture medium (Table 2) instead of the beef extract in Table 2 as the nitrogen source, and culturing at 37°C for 24 hours, and a good cultivation effect was obtained.

[0037] The product was used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com