Nickel-hydrogen storage battery electrode plate, nickel-hydrogen storage battery and preparation method thereof

A nickel-metal hydride storage battery and electrode plate technology, which is applied to alkaline battery electrodes, nickel storage batteries, alkaline storage batteries, etc., can solve the problems of short cycle life of nickel-hydrogen storage batteries, small battery capacity, and prone to thermal runaway, and achieve quality Reliable, stable discharge voltage, and the effect of avoiding thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

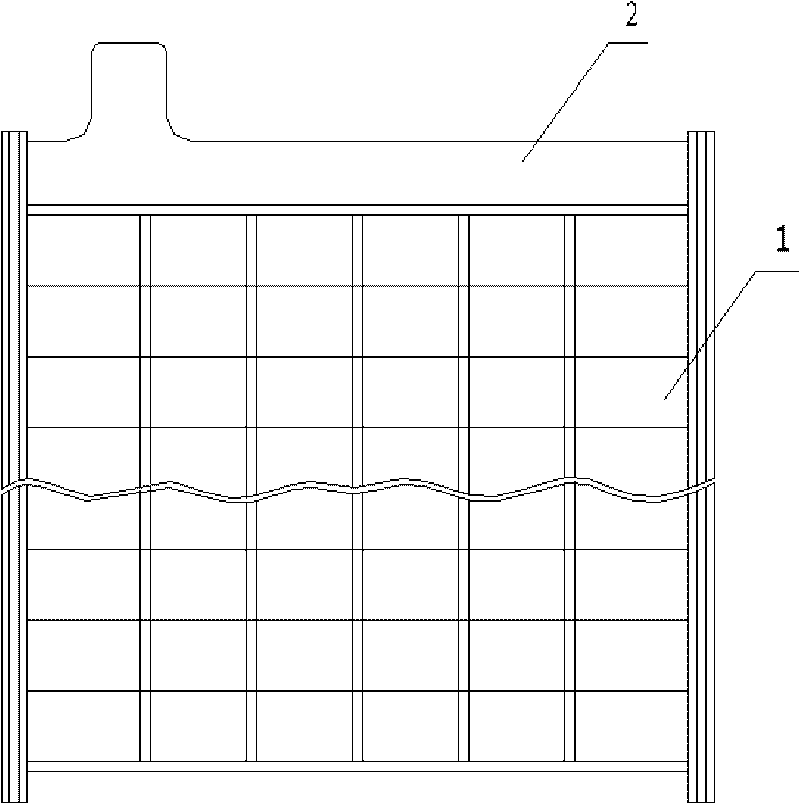

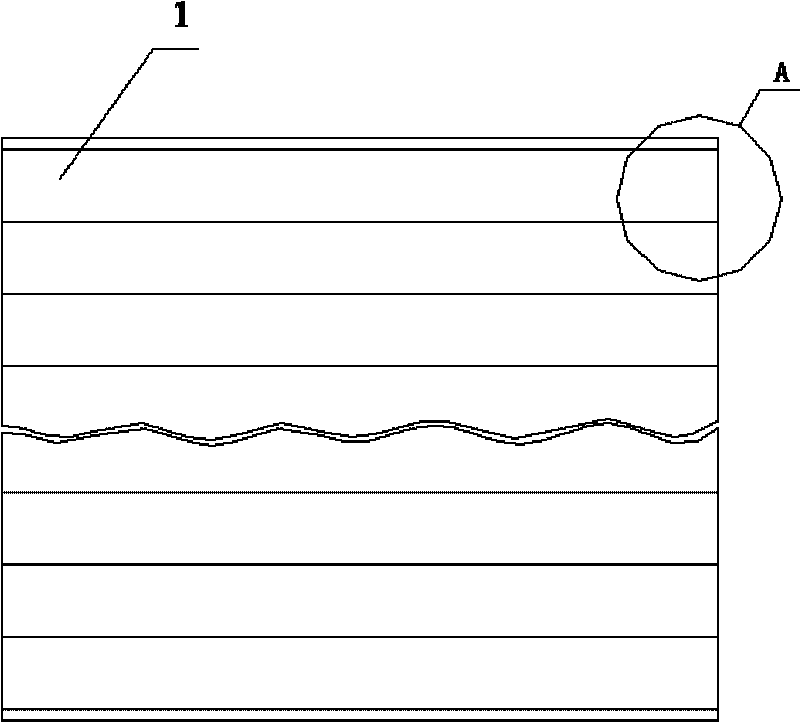

[0024] The preparation method of the nickel-metal hydride storage battery electrode plate of the present invention is: the positive and negative electrode active material that mixes evenly in powder form is wrapped in the perforated steel belt and is made into the pole strip 1, and then the required number of pole strips 1 are placed up and down Interlocked with each other, rolled by the roller of the embossing machine to form a whole large plate blank, cut the large plate blank into the required length of the plate blank by a shearing machine, install it in the plate frame 2, and The positive and negative plates of the nickel-metal hydride storage battery of the present invention are obtained after die stamping.

[0025] The nickel-hydrogen battery of the present invention comprises the above-mentioned nickel-hydrogen battery positive plate 3, negative plate 4, spacer 5, battery container 6, electrolyte, positive current collector 7, negative current collector 8, pole 9, etc.,...

Embodiment 1

[0029] (1) Preparation of the positive plate of the nickel-metal hydride storage battery: Mix nickelous hydroxide, flake graphite powder, and cobaltous oxide with a mixer in a mass ratio of 79.5:17.4:3.1 to make a positive active material, and use a powder coating machine to The positive active material is wrapped in a 0.1mm×25mm perforated steel strip, the weight of the 50mm strip of the control plate is 6.0g, and 14 strips are used for the plate blank, the weight of the control plate blank is 226g~234g, and the size of the plate blank is 138mm×194mm×3.5mm, the plate blank is put into the plate frame and punched to obtain the positive plate. The size of the positive plate is 141mm×231mm×3.7mm, and 10 positive plates are used;

[0030] (2) Preparation of the negative plate of the nickel-metal hydride storage battery: the hydrogen storage alloy powder (LaNi 5 ), flake graphite powder, and cobaltous oxide are mixed evenly with a mixer in a mass ratio of 97: 2: 1 to make the nega...

Embodiment 2

[0037] (1) Preparation of the positive plate of the nickel-metal hydride storage battery: Mix nickelous hydroxide, flake graphite powder, and cobaltous oxide with a mixer in a mass ratio of 80:17.5:2.5 to make the positive active material, and put the The positive active material is wrapped in a 0.1mm×25mm perforated steel strip, the weight of the 50mm strip of the control plate is 6.0g, and 17 strips are used for the plate blank, the weight of the control plate blank is 297g~308g, and the size of the plate blank is 148mm×230mm×3.3mm, the plate blank is put into the plate frame and punched to obtain the positive plate. The size of the positive plate is 151mm×268mm×3.3mm, and 15 positive plates are used;

[0038] (2) Preparation of the negative plate of the nickel-metal hydride storage battery: the hydrogen storage alloy powder (LaNi 5), flake graphite powder, and cobaltous oxide are uniformly mixed with a mixer in a mass ratio of 95: 4: 1 to make the negative active material, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com