Granulating coated slow release product of cysteamine hydrochloride and preparation method thereof

A technology for producing cysteamine hydrochloride and cysteamine hydrochloride is applied in the field of cysteamine hydrochloride granulation-coated sustained-release products and its preparation, which can solve the problem of low proportion of sustained-release materials and coating, Palatability and stability issues, affecting product use effects and other issues, to achieve the effect of enhancing the effect of relaxation, stabilizing technical support, and increasing palatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

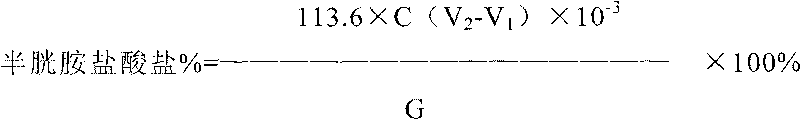

Method used

Image

Examples

Embodiment 1

[0048] 1. Formula:

[0049] Cysteamine hydrochloride 50 kg;

[0050] 50kg cornstarch

[0051] Vitamin C 1.5 kg;

[0052] 40 kg of glucose powder;

[0053] Stearic acid 10 kg;

[0054] 4.0 kg of 85wt% phosphoric acid;

[0055] All the above-mentioned raw materials can be purchased in the raw material market.

[0056] Second, the operation process steps are as follows:

[0057] (1) Melting of cysteamine hydrochloride: put cysteamine hydrochloride and vitamin C in a plastic container, heat in a boiling water bath until completely dissolved, and heat to 80°C.

[0058] (2) Add glucose powder and melt: when the temperature of the molten liquid reaches 80°C, add food-grade glucose powder, heat and stir until completely dissolved, and heat to 90°C.

[0059] (3) Maillard reaction: when the temperature of the molten liquid reaches 90°C, heat and stir in a boiling water bath to carry out the Maillard reaction, and the reaction time is 85 minutes.

[0060] (4) Cooling, adding 85wt...

Embodiment 2

[0071] 1. Formula:

[0072] Cysteamine hydrochloride 52 kg;

[0073] 50kg cornstarch

[0074] Vitamin C 1.25 kg;

[0075] Glucose 42 kg;

[0076] Stearic acid 8 kg;

[0077] 85wt% phosphoric acid 4.25 kg;

[0078] All the above-mentioned raw materials can be purchased in the raw material market.

[0079] Second, the operation process steps are as follows:

[0080] (1) Melting of cysteamine hydrochloride: put cysteamine hydrochloride and vitamin C in a plastic container, heat in a boiling water bath until completely dissolved, and heat to 85°C.

[0081] (2) Add glucose powder and melt: when the temperature of the molten liquid reaches 85°C, add food-grade glucose powder, heat and stir until completely dissolved, and heat to 95°C.

[0082] (3) Maillard reaction: when the temperature of the molten liquid reaches 95° C., heat and stir in a boiling water bath to carry out Maillard reaction, and the reaction time is 100 minutes.

[0083] (4) Cooling, add 85wt% phosphoric aci...

Embodiment 3

[0093] 1. Formula:

[0094] Cysteamine hydrochloride 54 kg;

[0095] 52kg cornstarch

[0096] Vitamin C 1.5 kg;

[0097] Glucose 45 kg;

[0098] Stearic acid 10 kg;

[0099] 5.5 kg of 85wt% phosphoric acid;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com