Granulating coated slow release product of cysteamine hydrochloride and preparation method thereof

A technology for making cysteamine hydrochloride and cysteamine hydrochloride, which is applied in the field of cysteamine hydrochloride granulation-coated sustained-release products and its preparation, to increase stability, not easily oxidize, and enhance slow-release suitable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

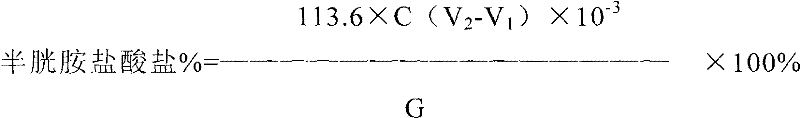

Method used

Image

Examples

Embodiment 1

[0050] 1. Formula:

[0051] Cysteamine hydrochloride 50 kg;

[0052] 50 kg cornstarch

[0053] Vitamin C 1.5 kg;

[0054] 40 kg of glucose powder;

[0055] Stearic acid 10 kg;

[0056] 4.0 kg of 85wt% phosphoric acid;

[0057] All the above-mentioned raw materials can be purchased in the raw material market.

[0058] Second, the operation process steps are as follows:

[0059] (1) Melting of cysteamine hydrochloride: put cysteamine hydrochloride and vitamin C in a plastic container, heat in a boiling water bath until completely dissolved, and heat to 80°C.

[0060] (2) Add glucose powder and melt: when the temperature of the molten liquid reaches 80°C, add food-grade glucose powder, heat and stir until completely dissolved, and heat to 90°C.

[0061] (3) Maillard reaction: when the temperature of the molten liquid reaches 90°C, heat and stir in a boiling water bath to carry out the Maillard reaction, and the reaction time is 85 minutes.

[0062] (4) Cooling, adding 85w...

Embodiment 2

[0073] 1. Formula:

[0074] Cysteamine hydrochloride 52 kg;

[0075] 50 kg cornstarch

[0076] Vitamin C 1.25 kg;

[0077] Glucose 42 kg;

[0078] Stearic acid 8 kg;

[0079] 85wt% phosphoric acid 4.25 kg;

[0080] All the above-mentioned raw materials can be purchased in the raw material market.

[0081] Second, the operation process steps are as follows:

[0082] (1) Melting of cysteamine hydrochloride: put cysteamine hydrochloride and vitamin C in a plastic container, heat in a boiling water bath until completely dissolved, and heat to 85°C.

[0083] (2) Add glucose powder and melt: when the temperature of the molten liquid reaches 85°C, add food-grade glucose powder, heat and stir until completely dissolved, and heat to 95°C.

[0084] (3) Maillard reaction: when the temperature of the molten liquid reaches 95° C., heat and stir in a boiling water bath to carry out Maillard reaction, and the reaction time is 100 minutes.

[0085] (4) Cooling, add 85wt% phosphoric ac...

Embodiment 3

[0095] 1. Formula:

[0096] Cysteamine hydrochloride 54 kg;

[0097] 52kg cornstarch

[0098] Vitamin C 1.5 kg;

[0099] Glucose 45 kg;

[0100] Stearic acid 10 kg;

[0101] 5.5 kg of 85wt% phosphoric acid;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com