Monodisperse mesoporous silica nano-particle with controllable appearance and synthesis method thereof

A technology of mesoporous silica and nanoparticles, which is applied in the direction of silica, silicon oxide, nanotechnology, etc., can solve the difficulties of synthesizing mesoporous silica, and the synthesis of mesoporous silica has not been reported. Achieve excellent adsorption and separation performance, wide application, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

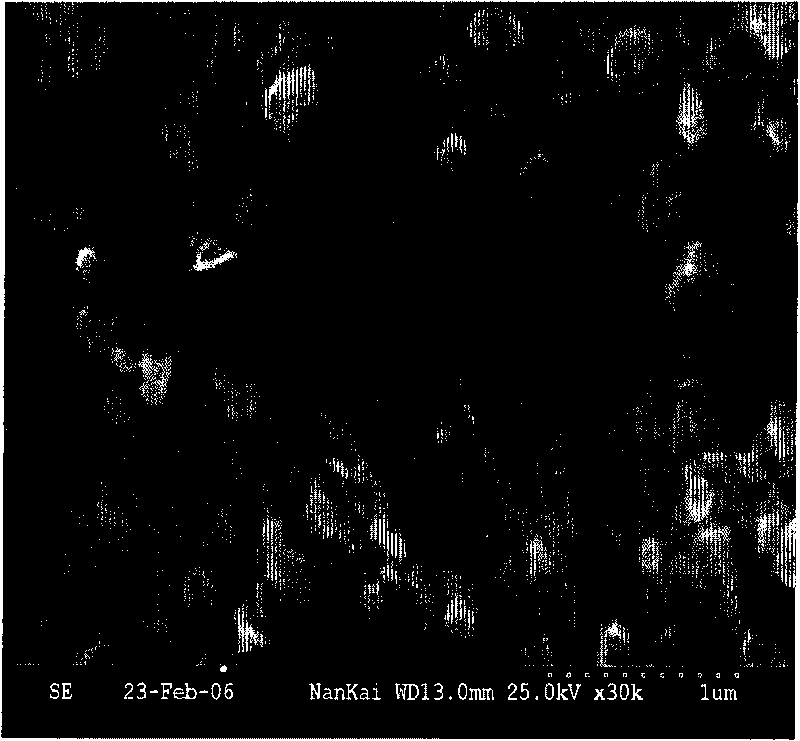

Embodiment 1

[0047] At room temperature, 5.68g of sodium silicate (Na 2 SiO 3 9H 2 O) Dissolve in 25ml deionized water. In another reaction flask, 3.494g of cetyltrimethylammonium bromide was dissolved in 35ml of deionized water, and 16ml of 2.4M hydrochloric acid was added. Under rapid stirring, quickly add the above sodium silicate solution into the mixed solution containing surfactant and acid (the molar ratio of silicon source to surfactant is 1:0.48), at this time the solution is neutral, and a large amount of precipitates are formed immediately . Stirring was continued for 2 hours. Add 6ml of concentrated ammonia water (28% by mass fraction), and stir for another 2.5 hours. The solid product was collected by filtration and washed with deionized water. After drying, it was calcined at 550° C. for 6 hours to obtain the final product.

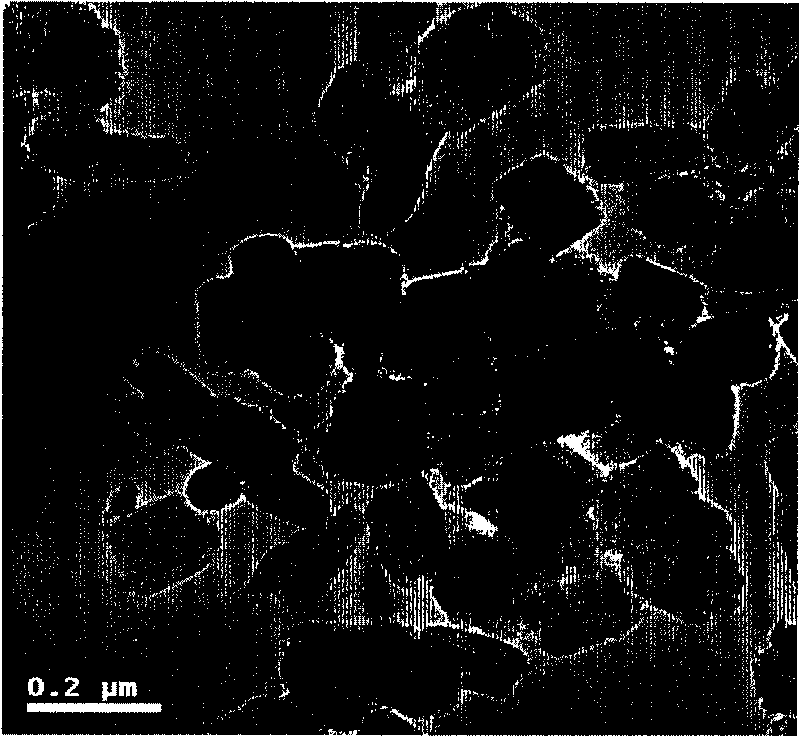

Embodiment 2

[0049] At room temperature, 5.68g of sodium silicate (Na 2 SiO 3 9H 2 O) Dissolve in 25ml deionized water. In another reaction flask, 1.747g of cetyltrimethylammonium bromide was dissolved in 35ml of deionized water, and 16ml of 2.4M hydrochloric acid was added. Under rapid stirring, the above-mentioned sodium silicate solution was quickly added to the mixed solution containing surfactant and acid (the molar ratio of silicon source to surfactant was 1:0.24), and a large amount of precipitation was formed immediately. Stirring was continued for 2 hours. Add 6ml of concentrated ammonia water (28% by mass fraction), and stir for another 2.5 hours. The solid product was collected by filtration and washed with deionized water. After drying, it was calcined at 550° C. for 6 hours to obtain the final product.

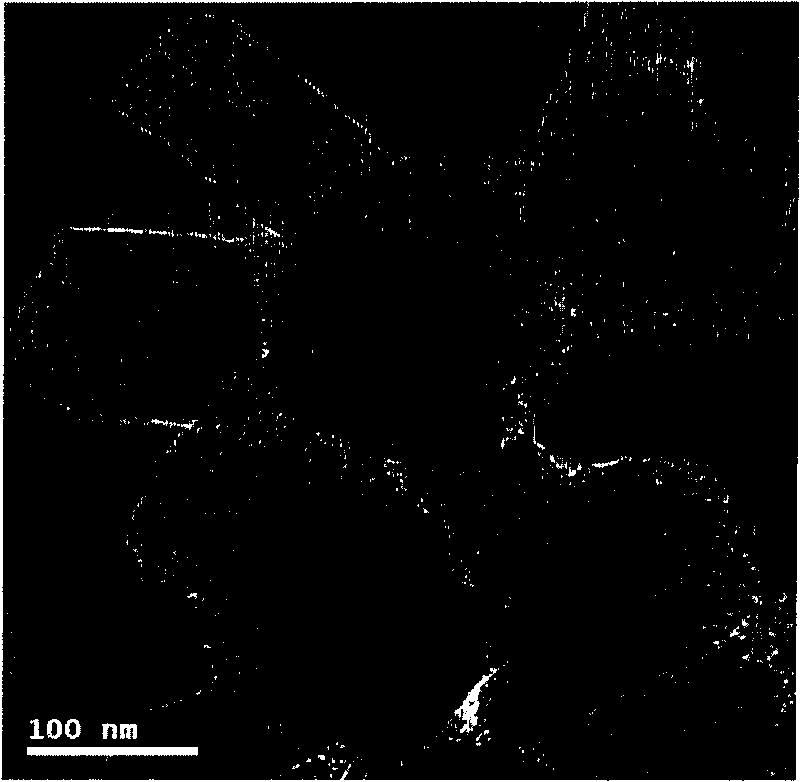

Embodiment 3

[0051] At room temperature, 5.68g of sodium silicate (Na 2 SiO 3 9H 2 O) Dissolve in 25ml deionized water. In another reaction flask, 3.070 g of cetyltrimethylammonium chloride was dissolved in 35 ml of deionized water, and 16 ml of 2.4M hydrochloric acid was added. Under rapid stirring, the above-mentioned sodium silicate solution was quickly added to the mixed solution containing surfactant and acid (the molar ratio of silicon source to surfactant was 1:0.48), and a large amount of precipitation was formed immediately. Stirring was continued for 2 hours. Add 6ml of concentrated ammonia water (28% by mass fraction), and stir for another 2.5 hours. The solid product was collected by filtration and washed with deionized water. After drying, it was calcined at 550° C. for 6 hours to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com