Method for extracting chlorogenic acid

An extraction method, chlorogenic acid technology, applied in the field of chlorogenic acid extraction and purification technology, can solve the problems of unfavorable chlorogenic acid preservation, complicated post-processing, and difficulty in meeting optimal conditions, so as to shorten the production cycle and ensure extraction effect, the effect of saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

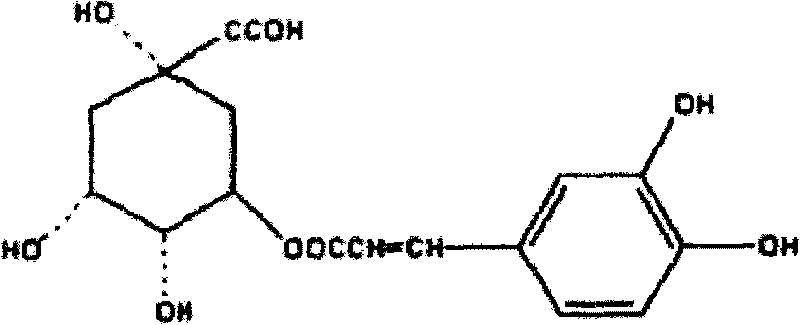

Image

Examples

Embodiment 1

[0029] Get 10kg of fresh leaves of eucommia ulmoides (3.8% chlorogenic acid content), pressurize to 80MPa in the press, adjust the pH to 4 with sulfuric acid, pass through the NKA-II macroporous resin column with a column volume of 5L, and use 20L deionized water respectively Wash away impurities with 10L 18% ethanol, then elute chlorogenic acid with 20L 50% ethanol, collect the eluate, and finally remove macromolecular impurities through a hollow fiber ultrafiltration membrane with a molecular weight cut-off of 2000, and then use DK4040 type The nanofiltration membrane is concentrated, and the concentrated solution is spray-dried to finally obtain 352 g of chlorogenic acid finished product with a content of 90.5%.

Embodiment 2

[0031] Get 15kg of fresh leaves of Eucommia ulmoides (3.9% chlorogenic acid content), pressurize to 90MPa in the press, adjust the pH to 3.5 with phosphoric acid, pass through the NKA-9 macroporous resin column with a column volume of 5L, and use 25L deionized water and 10L of 20% ethanol was used to wash away impurities, and then 23L of 50% ethanol was used to elute chlorogenic acid, and the eluate was collected. Finally, the eluate was first passed through a hollow fiber ultrafiltration membrane with a molecular weight cut-off of 2000 to remove macromolecular impurities, and then the DL4040 nanometer filter was used to remove impurities. The filter membrane was concentrated, and the concentrated solution was spray-dried to finally obtain 545 g of finished chlorogenic acid with a content of 94.2%.

Embodiment 3

[0033] Get 20kg of fresh leaves of eucommia ulmoides (3.8% chlorogenic acid content), pressurize to 100MPa in an extruder, adjust the pH to 3 with hydrochloric acid, pass through the HZ-806 macroporous resin column with a column volume of 5L, and use 30L deionized water and 10L of 10% ethanol was used to wash away impurities, and then 25L of 50% ethanol was used to elute chlorogenic acid, and the eluate was collected. Finally, the eluate was first passed through a hollow fiber ultrafiltration membrane with a molecular weight cut-off of 2000 to remove macromolecular impurities, and then used JY-NF300 Concentrate with a type nanofiltration membrane, and the concentrated solution is spray-dried to finally obtain 673g of chlorogenic acid finished product with a content of 96.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com