Precision injection molding polyamide composite and preparation method thereof

A composite material, injection molding technology, applied in the field of precision injection molding, can solve the problems of poor toughness, increased shrinkage, easy water break, etc., to achieve the effect of improving the bending elastic modulus, improving the thermal deformation temperature, and accelerating the crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 A precision injection molding grade polyamide composite material, containing components and the weight percentage of each component is: PA6 or PA66 49.4%; E-type glass fiber 50%; nucleating agent 0.2%; flow agent 0.2%; The oxygen agent is 0.2%, wherein the nucleating agent is calcium salt of carboxylate with long carbon chain as the main component; the flow agent is an optimized mixture of copolymer and montanic acid derivative; the antioxidant is inorganic phosphate.

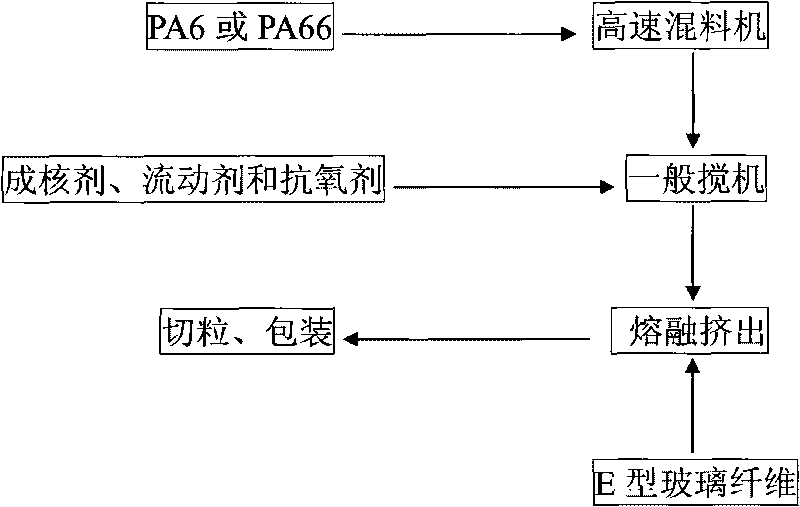

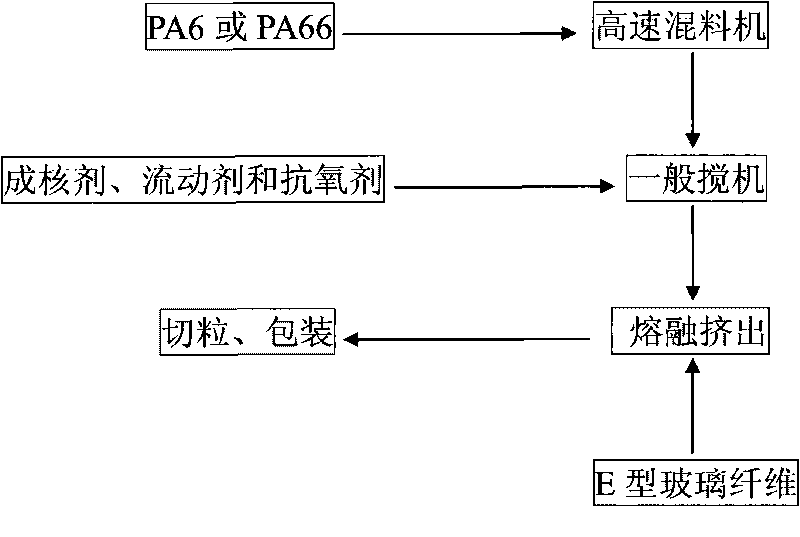

[0038] The preparation method of the above-mentioned precision injection molding grade polyamide composite material is as follows:

[0039] (1) Take PA6 or PA66, put it into a high-speed mixer and mix well;

[0040] (2) Get nucleating agent, flow agent and antioxidant and step (1) gained nylon material and put into general mixer and stir;

[0041] (3) Put the mixture obtained in step (2) into the screw machine, add E-type glass fiber at the same time, mix it, and melt it at a temperature of 25...

Embodiment 2

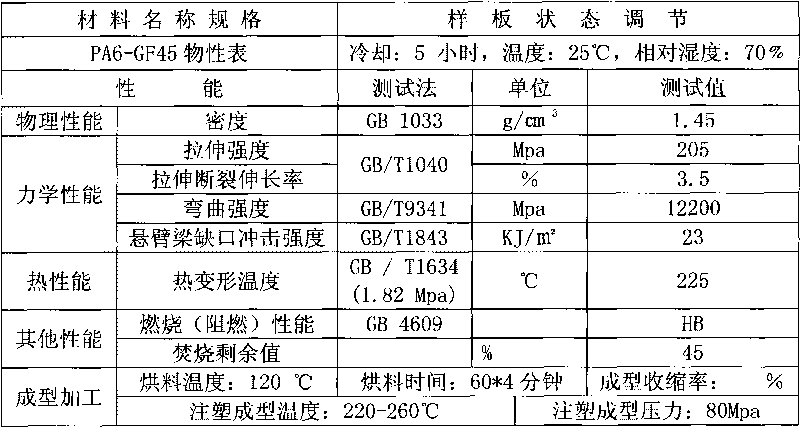

[0043] Example 2 A precision injection molding grade polyamide composite material, containing components and the weight percentage of each component is: PA6 or PA66 54.4%; E-type glass fiber 45%; nucleating agent Licomont CaV102 0.2%; flow agent BRUGGOLEN P12 0.2%; antioxidant BRUGGOLEN H10 0.2%.

[0044] Its preparation method is with embodiment 1

Embodiment 3

[0045] Example 3 A precision injection molding polyamide composite material, containing components and the weight percentage of each component: PA6 or PA66 52%; E-type glass fiber 47.4%; nucleating agent CaV102 0.2%; flow agent BRUGGOLENP12 0.2%; Antioxidant BRUGGOLEN H10 0.2%.

[0046] Its preparation method is with embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com