Method for deeply processing waste water from paper making

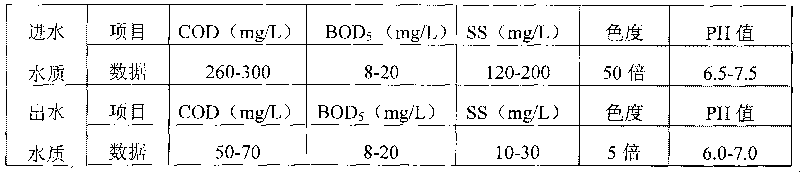

A technology for papermaking wastewater and advanced treatment, which is applied in processing wastewater treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc. requirements, etc., to achieve the effect of good chromaticity removal, low investment and high pollutant removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

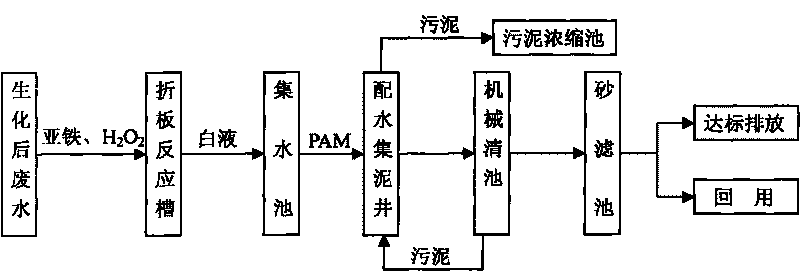

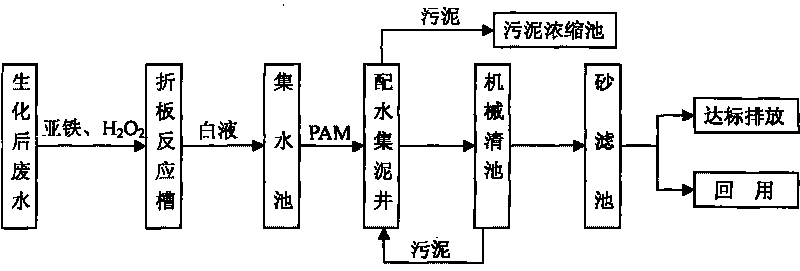

Method used

Image

Examples

Embodiment 1

[0020] (1) The papermaking wastewater after secondary biochemical treatment, on the pipeline flowing to the sump, first add ferrous chloride with a concentration of 25% by weight, adjust the pH value to 3, and then add a concentration of 5% by weight % hydrogen peroxide, the volume ratio of the ferrous chloride solution and the hydrogen peroxide solution is 1.2: 1, the sewage mixed with the above two medicaments and the secondary biochemical wastewater enters the folding plate reaction tank, and reacts in the folding plate The residence time in the tank is 1 minute, and after the sewage flows out of the folding plate reaction tank, add the white liquor to adjust the pH value of the sewage to 7;

[0021] (2) The reaction of hydrogen peroxide and ferrous chloride releases a large amount of carbon dioxide, which is shown as a large number of small air bubbles in the water. A mixer is set in the sump for stirring. Make the small bubbles in the water overflow the water surface, pre...

Embodiment 2

[0027] (1) Papermaking wastewater after secondary biochemistry is introduced into the sump through pipelines, and on the pipeline flowing to the sump, it is first added a medicament ferrous sulfate solution with a concentration of 20% by weight to adjust the pH value to 2.5, and then add 100% by weight Concentration is 4.5% agent hydrogen peroxide solution, the volume ratio of described ferrous sulfate solution and hydrogen peroxide solution is 1.2:1, the sewage after the above two kinds of agents are mixed with secondary biochemical papermaking wastewater enters the folding plate reaction Tank, the residence time in the folding plate reaction tank is 1.5 minutes, after the sewage flows out of the folding plate reaction tank, add the white liquor of the medicine, and adjust the pH value of the sewage to 6;

[0028] (2) The sewage mixed with the three kinds of medicaments in step (1) enters the sump, and the sump has a mixer for stirring, and the medicament and the sewage furthe...

Embodiment 3

[0034] (1) papermaking waste water after secondary biochemistry, introduce sump through pipeline, on the pipeline that flows to sump, add weight percent concentration earlier and be 30% medicament ferrous chloride salt solution and adjust pH value to be 3.5, then add weight Percentage concentration is 5.5% medicament hydrogen peroxide solution, the volume ratio of described ferrous chloride solution and hydrogen peroxide solution is 1.2: 1, the sewage after above-mentioned two kinds of medicaments are mixed with secondary biochemical papermaking waste water enters folding Plate reaction tank, the residence time in the folded plate reaction tank is 2 minutes, after the sewage flows out of the folded plate reaction tank, white liquor is added to adjust the pH value of the sewage to 8;

[0035] (2) The sewage mixed with the three kinds of medicaments in step (1) enters the sump, and the sump has a mixer for stirring, and the medicament and the sewage further fully react in the sum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com