Sludge drying incineration processing system utilizing system residual heat

A technology of sludge drying and sludge incineration, applied in dehydration/drying/concentrated sludge treatment, incinerators, combustion methods, etc., can solve problems such as prone to reaction, easy to corrode equipment, and reduced system economy, and achieve Improve energy utilization efficiency, improve system economy, and reduce heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

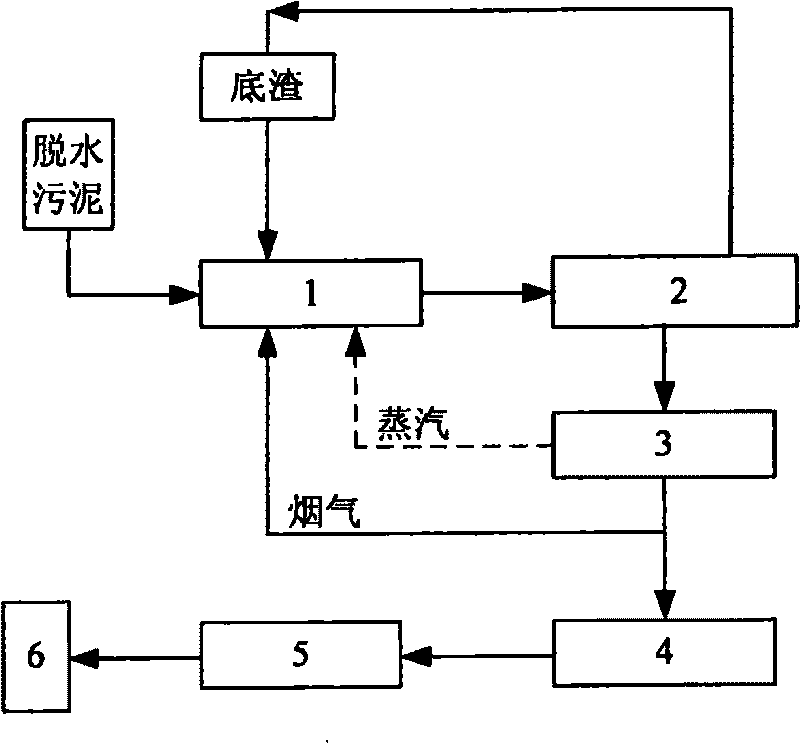

[0030] Example 1: The sludge semi-drying device adopts a fluidized bed dryer

[0031]The semi-drying process is carried out in the bubbling fluidized bed. The flue gas enters the bed from the bottom of the bed through the hood, and the sludge, bottom slag and fly ash are sent in from different feeding ports. On the one hand, the hot flue gas makes the bed The sludge is fluidized to prevent the sludge from sticking; on the other hand, it also fully exchanges heat with the sludge to evaporate the water in it, and the evaporated water is mixed with the flue gas, which is also conducive to reducing the dust content in the flue gas. Reduce load on e.g. baghouses. At the same time, the use of this system also helps to prevent the odor from overflowing during the drying process and reduce pollution. The odor and flue gas enter the tail flue gas treatment system together and are discharged after treatment. When the waste heat of the bottom slag and flue gas is not enough to provide t...

Embodiment 2

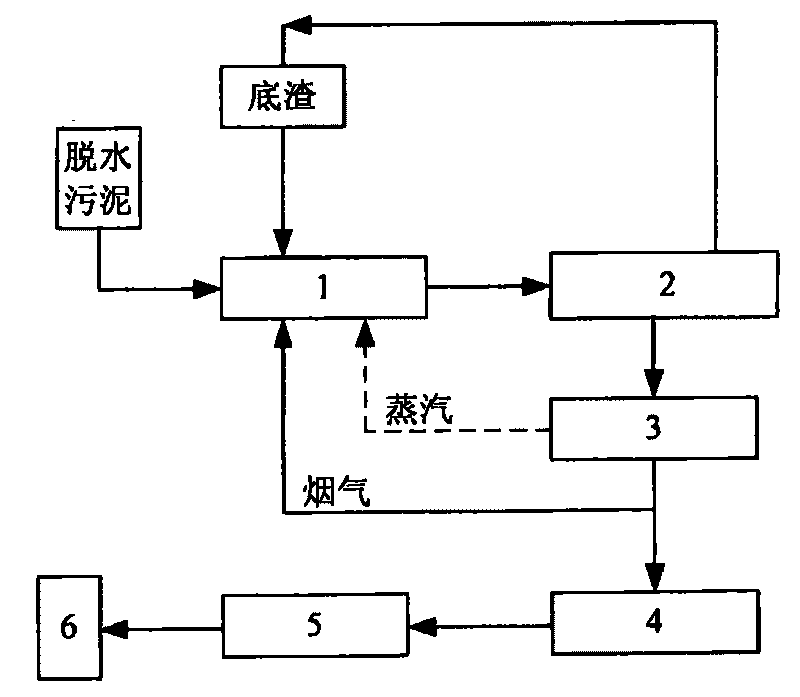

[0032] Example 2: The sludge semi-drying device adopts a drum structure

[0033] Bottom slag and sludge enter together from the top of the drum, and the two are slowly mixed in the drum to fully exchange heat and semi-dry the sludge. At the same time, the above-mentioned flue gas is introduced from the bottom of the drum, and the flue gas flows upstream, collects from the outlet on the top of the drum, and then enters the bag filter, which can effectively use the waste heat, thereby greatly improving the energy utilization efficiency of the system. Heat exchange tubes are arranged in the drum, and the number of arrangement depends on the actual situation. When the waste heat of the bottom slag and flue gas is not enough to provide the heat required for the semi-drying of the sludge, the steam from the waste heat boiler can be passed through the exchange tube set in the drum. Heat pipes dry the sludge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com