Control system for viscosity of compound fertilizer slurry

A technology for controlling system and slurry viscosity, applied in the direction of control/adjustment system, viscosity control, non-electric variable control, etc. It can solve the problems that large particles are difficult to dissolve, waste, and cannot completely absorb fertilizers, etc., and achieve high utilization rate and easy The effect of absorption and nutrient uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

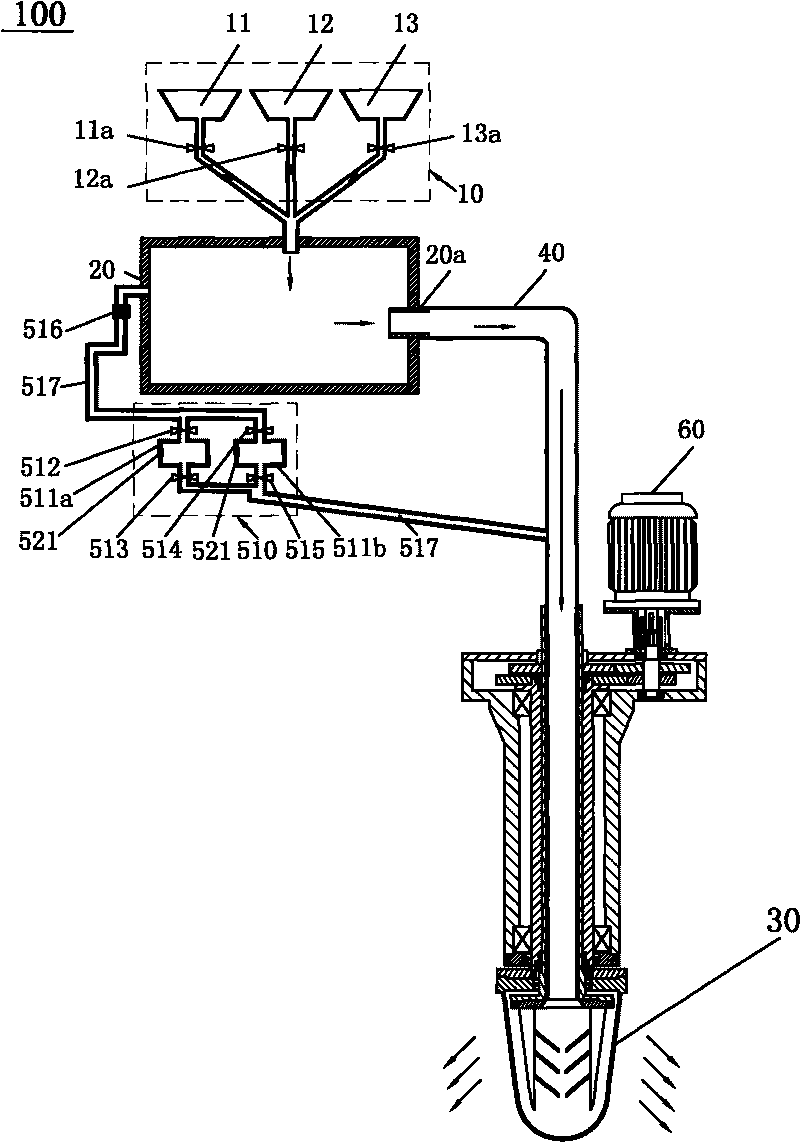

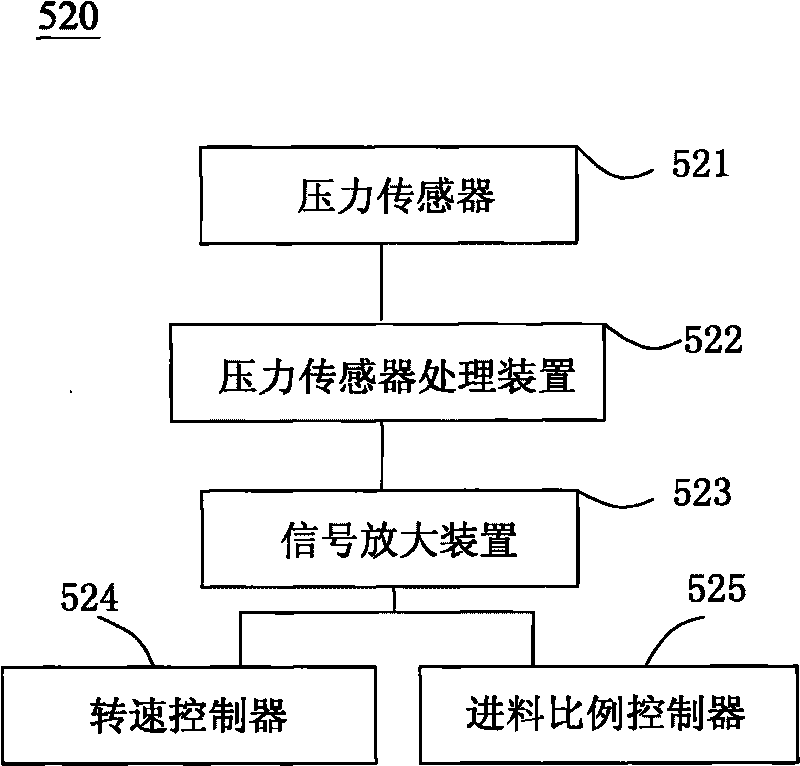

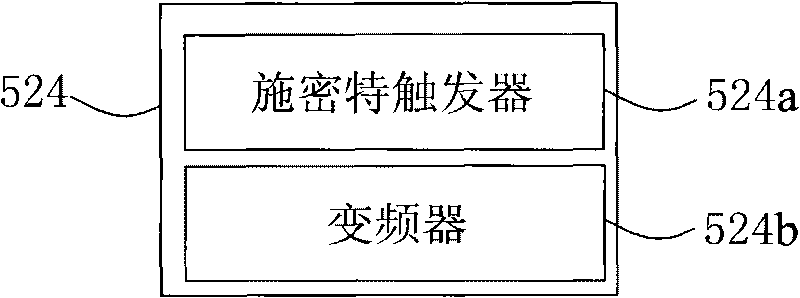

[0025] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a kind of control system of compound fertilizer slurry viscosity, the control system of described compound fertilizer slurry viscosity utilizes the rotational speed controller and feed rate controller to control the slurry viscosity of compound fertilizer simultaneously, thereby makes The particle size of the produced compound fertilizer is uniform and easy to absorb, so that the utilization rate of the compound fertilizer is high, the nutrient is uniform, and the fertilization effect and sales volume are greatly improved.

[0026] refer to Figure 1-3 , the control system 100 of the viscosity of the compound fertilizer slurry comprises a feed mechanism 10, a mixing tank 20, a rotary nozzle 30, a slurry conduit 40, a control system 50 and a rotary nozzle motor 60, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com