Novel carbon paste electrode and preparation method thereof

A carbon paste electrode and a new technology, applied in the field of electrochemical analysis, can solve problems such as poor performance of carbon paste electrode, and achieve the effects of improved electrochemical performance, improved mechanical performance, and improved long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

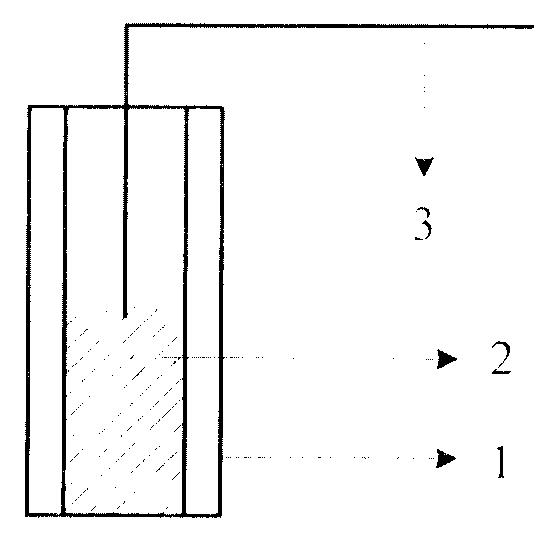

[0019] A new type of carbon paste electrode, which includes a glass tube 1 as an electrode sleeve, a lead wire 3, and a carbon paste 2 filled in the glass tube; the carbon paste 2 is formed by mixing graphite powder and triphenylamine, graphite The mass ratio of powder and triphenylamine is 7:3, the inner diameter of the glass tube is 1.8 mm, and the lead wire is copper wire. The electrode sleeve can also be a hollow tube made of polymer material.

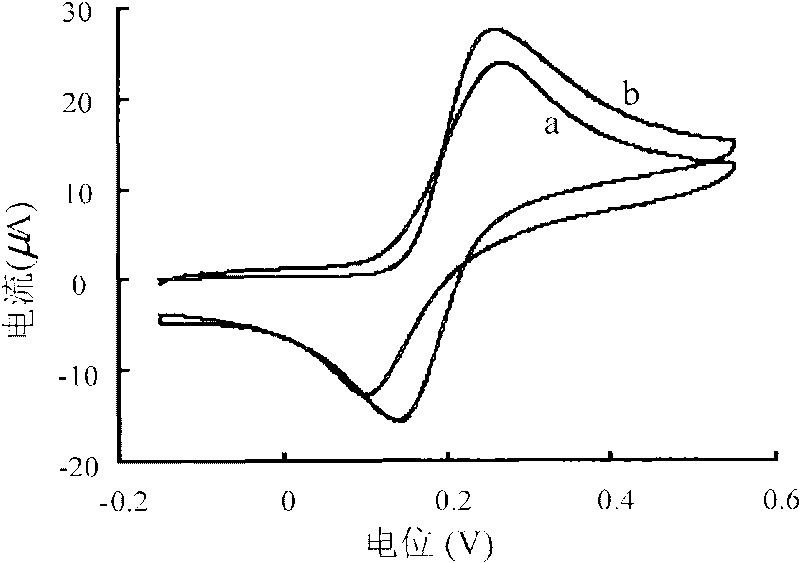

[0020] The preparation method of the carbon paste electrode based on this ratio is as follows: Weigh 0.70g of graphite powder and 0.30g of triphenylamine and mix thoroughly, stuff it into the glass tube 1 and compact it, then heat it in an oven for 3 minutes, and the temperature is controlled at 125 ℃~130℃, after the conductive carbon material and triphenylamine are bonded together, take it out and cool it at room temperature for half an hour. As a comparison, a carbon paste electrode of the same composition was prepared without t...

Embodiment 2

[0028] In this embodiment, the carbon paste is prepared by thoroughly mixing 0.60 g of graphite powder and 0.40 g of triphenylamine, and the remaining is the same as the new carbon paste electrode described in Example 1, and the preparation method is also the same.

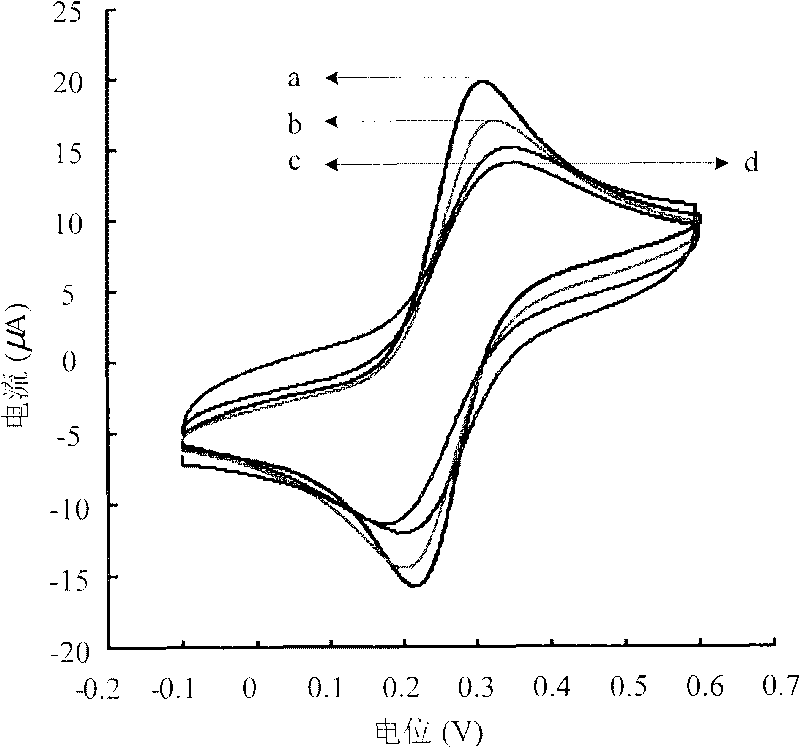

[0029] refer to Figure 6 For line b, the carbon paste electrode was placed in 1mM potassium ferricyanide and 0.1M potassium chloride solution, and the cyclic voltammetry scan was performed in the potential range of -0.1V-+0.6V. Obvious redox peaks can be obtained, and the peak potential difference is very small.

example 3

[0031] In this embodiment, the carbon paste is prepared by fully mixing 0.50 g of graphite powder and 0.50 g of triphenylamine, and the remaining is the same as the new carbon paste electrode described in Example 1, and the preparation method is also the same.

[0032] refer to Figure 6 For line c, the prepared carbon paste electrode was placed in 1mM potassium ferricyanide and 0.1M potassium chloride solution, and the cyclic voltammetry scan was performed in the potential range of -0.1V-+0.6V. Obvious redox peaks can be obtained, and the peak potential difference is very small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com