Laser processing method and laser processing apparatus

A laser processing method and laser processing technology, applied in cleaning methods and utensils, laser welding equipment, metal processing equipment, etc., can solve problems such as unfavorable manufacturing speed and quality reduction, and achieve the goal of facilitating manufacturing speed, shortening time, and facilitating high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

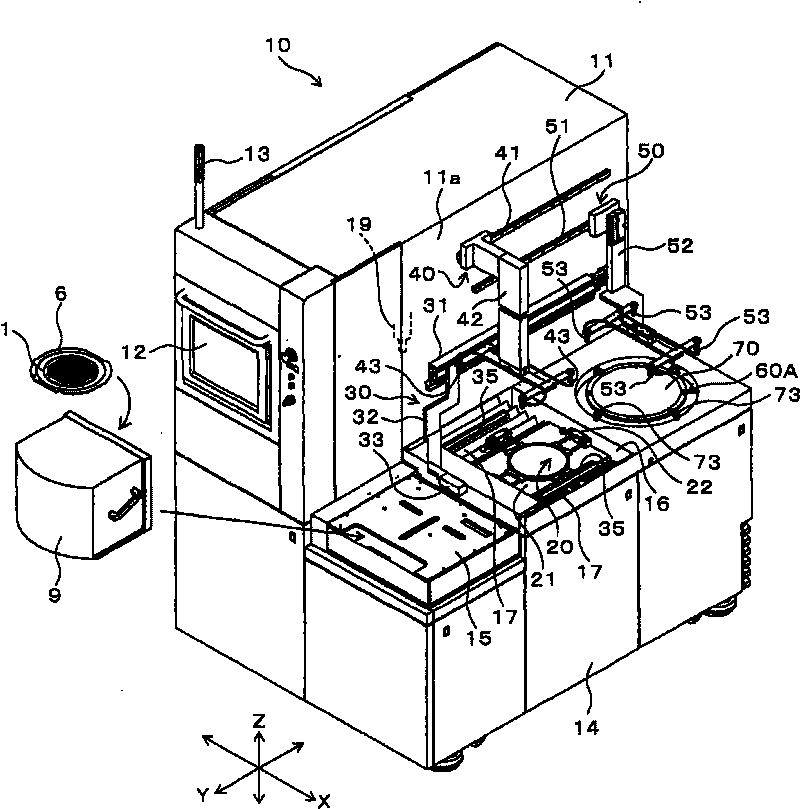

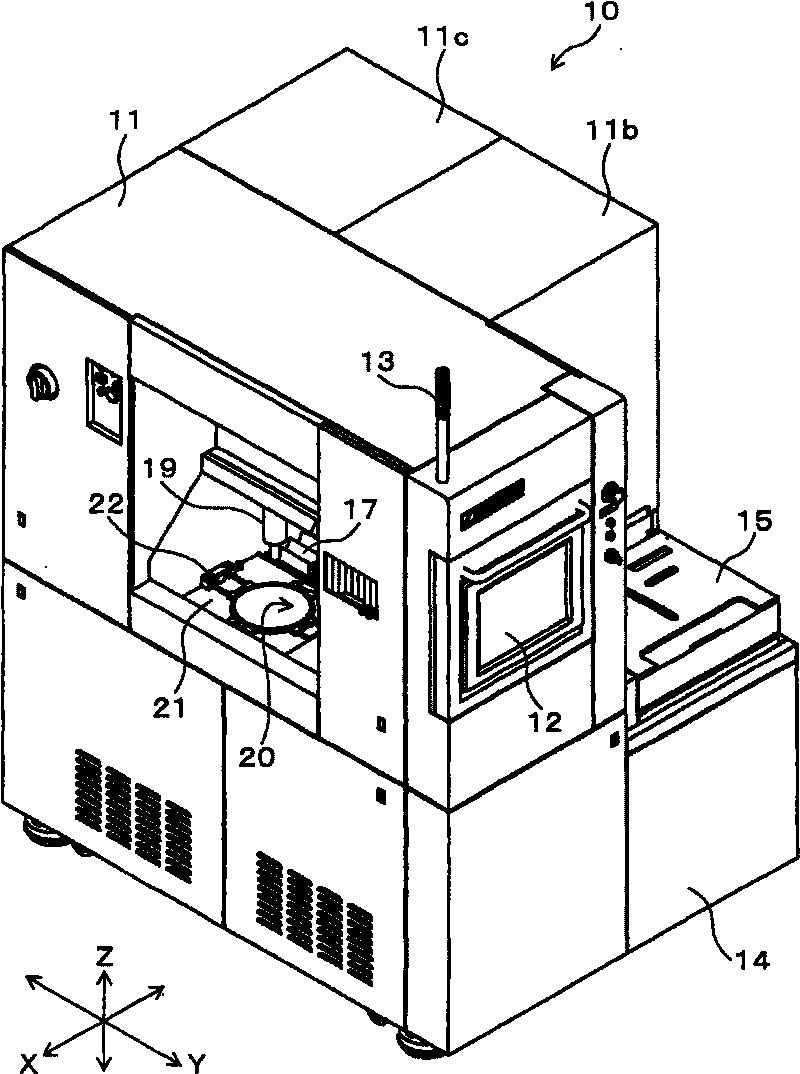

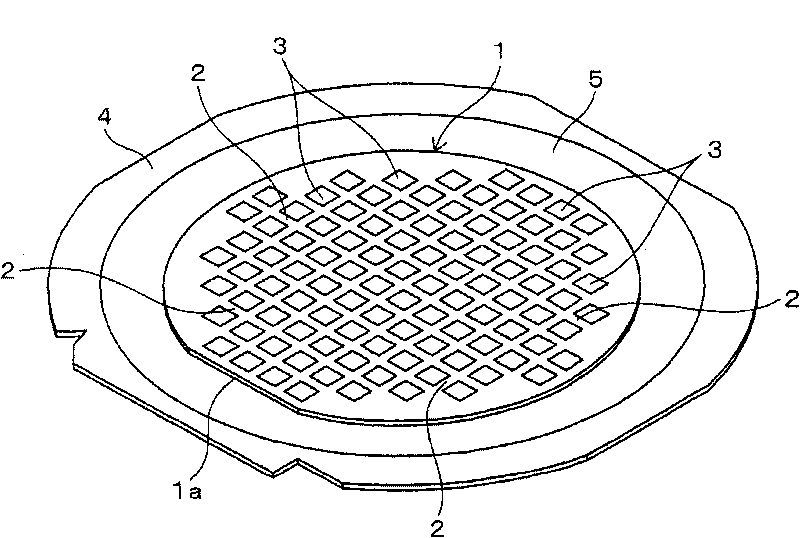

[0028] figure 1 It shows the whole of the laser processing apparatus 10 of one embodiment, figure 2 Indicates the back side. The device 10 is based on image 3 The shown semiconductor wafer (hereinafter, simply referred to as wafer) 1 is a laser cutting device that cuts the wafer 1 by automatic control as a workpiece.

[0029] (1) chip

[0030] use image 3First, the wafer 1 will be described. This wafer 1 is a disk-shaped wafer made of a single crystal material such as silicon. On a part of the outer peripheral portion of the wafer 1, an orientation flat portion (orientation flat) 1a is formed as a mark indicating the orientation of the crystal. . On the surface (processing surface) of the wafer 1, a large number of rectangular chips 3 are divided by dividing lines 2 formed in a grid pattern. On the surface of each chip 3, circuits such as ICs and LSIs (not s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com