Super high molecular weight ethylene-alpha-olefin copolymer powder

An olefin copolymer, ultra-high molecular weight technology, applied in transportation and packaging, thin material processing, etc., can solve the problems of reduced mechanical strength, insufficient transparency, increased extracts, etc., and achieve the effect of excellent powder properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0126] Preparation of solid catalyst component (A)

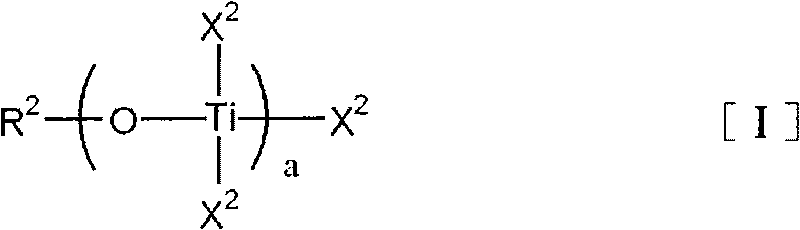

[0127] The solid catalyst component (A) can be obtained by using a titanium compound (ii) represented by the general formula [I] in the presence of an organosilicon compound (i) having a Si-O bond, using an organomagnesium compound (iii) The reduction is carried out, and the obtained solid component (a) is brought into contact with the halide (b) and the phthalic acid derivative (c). The above contact treatment is usually carried out under an atmosphere of inert gas such as nitrogen or argon.

[0128] Specific methods of the contact treatment to obtain the solid catalyst component (A) include the following methods and the like.

[0129] ・The method of putting (b) and (c) in (a) (arbitrary order of putting) and performing contact processing

[0130] ・The method of putting (a) and (c) in (b) (arbitrary order of putting) and performing contact processing

[0131] ・The method of putting (a) and (b) (arbitrary order of putting...

Embodiment 1

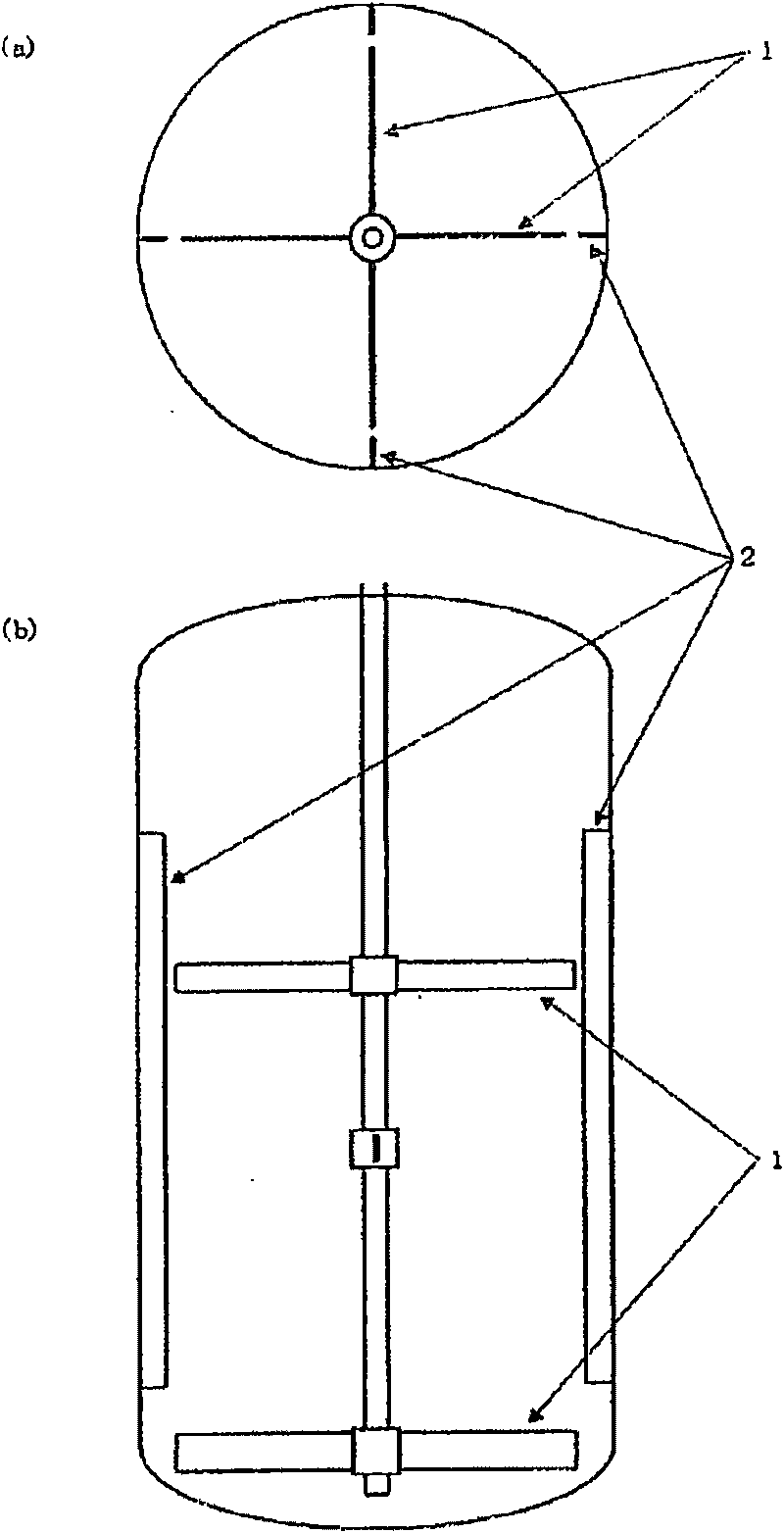

[0207] (1) Synthesis of solid catalyst component precursor

[0208] exist figure 1 Shown possesses the 500ml cylindrical reactor of stirrer, baffle (the stirrer that has 3 pairs of diameter 0.053m, the stirrer of wide 0.010m and the reactor with the diameter 0.07m of 4 wide 0.007m baffles, The power number is 3.02) filled with nitrogen gas, 270 ml of hexane, 8.1 ml of tetrabutoxytitanium and 79.9 ml of tetraethoxysilane were added and stirred. Next, while keeping the temperature of the reactor at 5° C., 182 ml of a dibutyl ether solution of butylmagnesium chloride (concentration: 2.1 mol / liter) was added dropwise to the above stirred mixture over 4 hours. The stirring rotation speed at this time was 700 rpm. After completion of the dropping, the mixture was stirred at 20° C. for 1 hour, filtered, and the obtained solid was repeatedly washed three times with 280 ml of toluene, and then added toluene to make the total volume 250 ml for slurrying. A part of the slurry was coll...

Embodiment 2

[0218] (1) Synthesis of solid catalyst component precursor

[0219] Equipped with the same 500ml cylindrical reactor of stirrer and baffle as in Example 1 (1), nitrogen is filled, and 270ml of hexane, 16.8ml of tetrabutoxytitanium, and 75.5ml of tetraethoxysilane are dropped into it. and 6.0 ml of diisobutyl phthalate, and stirred. Next, while keeping the temperature of the reactor at 45° C., 182 ml of a dibutyl ether solution of butylmagnesium chloride (concentration: 2.1 mol / liter) was added dropwise to the above stirred mixture over 4 hours. The stirring rotation speed at this time was 1000 rpm. After completion of the dropping, the mixture was stirred at 45°C for 1 hour, filtered, and the obtained solid was repeatedly washed three times with 280 ml of toluene, and then added toluene to make the total volume 250 ml for slurrying. A part of the slurry was collected, the solvent was removed and dried to obtain a solid catalyst component precursor.

[0220] This solid catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com