Artemisia dalai-lamae Krasch. essential oil and preparation method and application thereof

A technology of volatile oil and Artemisia annua, applied in pharmaceutical formulations, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of large treatment limitations, high disability rate, helplessness, etc., and achieve simple process flow and equipment investment. The effect of small size and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

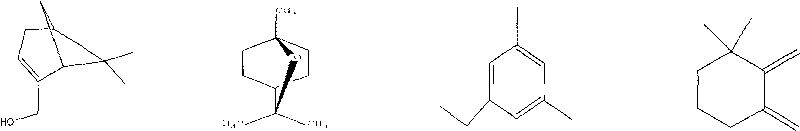

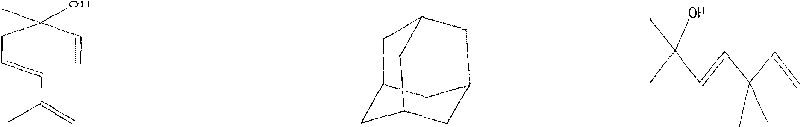

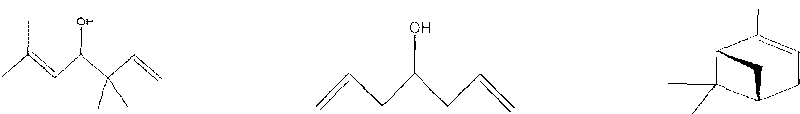

Image

Examples

Embodiment 1

[0042] Embodiment 1 A kind of preparation method of Artemisia sativa volatile oil, comprises the following steps:

[0043] (1) Remove impurities from 500g fresh twigs or fresh leaves of the above-ground part of Artemisia oryzae, cut them into sections of 0.5-3cm, put them into the volatile oil extractor produced by Shanghai Tongxin Biomedical Technology Co., Ltd., and use 4 times its weight Soak in water for 5 hours to fully infiltrate the broken pieces of Artemisia mirabilis.

[0044] (2) Move the volatile oil extractor containing Artemisia annua fragments and its soaking solution in step (1) to the 98-1-B electronic constant temperature electric heating mantle produced by Tianjin Test Instrument Co., Ltd. to carry out steam distillation , the distillation temperature was 80°C, the distillation time was 2h, and the distillate was collected.

[0045] (3) Natural cooling of the distillate, natural layering, discarding the water layer, taking the oil layer, drying with anhydrou...

Embodiment 2

[0046] Embodiment 2 A kind of preparation method of Artemisia sativa volatile oil, comprises the following steps:

[0047] (1) Remove impurities from 1 kg of fresh twigs or fresh leaves of the above-ground part of Artemisia japonica, cut them into sections of 0.5-3 cm, put them into a volatile oil extractor, soak them in water 10 times their weight for 2 hours, and make Artemisia japonica into pieces Fully infiltrate.

[0048] (2) Move the volatile oil extractor containing Artemisia annua fragments and its soaking solution in step (1) to the 98-1-B type electronic constant temperature electric heating mantle to carry out steam distillation, the distillation temperature is 120 ℃, and the distillation time is 6h, collect the distillate.

[0049] (3) Natural cooling of the distillate, natural layering, discarding the water layer, taking the oil layer, drying with anhydrous sodium sulfate in a weight ratio of 1:8, filtering out the solids to obtain the volatile oil of Artemisia m...

Embodiment 3

[0050] Embodiment 3 A kind of preparation method of Artemisia sativa volatile oil, comprises the following steps:

[0051] (1) Remove impurities from 2 kg of fresh twigs or fresh leaves of the above-ground part of Artemisia japonica, cut them into sections of 0.5-3 cm, put them in a volatile oil extractor, soak them in water 7 times their weight for 4 hours, and make Artemisia japonica into pieces Fully infiltrate.

[0052] (2) Move the volatile oil extractor containing Artemisia annua fragments and its soaking solution in step (1) to the 98-1-B type electronic constant temperature electric heating mantle to carry out steam distillation, the distillation temperature is 100 ℃, and the distillation time is 4h, collect the distillate.

[0053] (3) Natural cooling of the distillate, natural layering, discarding the water layer, taking the oil layer, drying with anhydrous sodium sulfate in a weight ratio of 1:5, and filtering out the solids to obtain the volatile oil of Artemisia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com