Hydrotalcite-like compound-based magnesium-zirconium-aluminum composite oxide catalyst and use thereof

A composite oxide and catalyst technology, applied in physical/chemical process catalysts, hydroxyl compound preparation, chemical/physical processes, etc., can solve the problems of increasing catalyst energy consumption, uneven grain dispersion, catalyst activity limitation, etc. The effect of mild conditions, uniform distribution and improved activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Preparation of hydrotalcite-like magnesium-zirconium-aluminum composite oxide (Mg / Zr / Al-LDO) catalyst

[0026] The preparation of the precursor magnesium-zirconium-aluminum hydrotalcite (Mg / Zr / Al-LDH): by co-precipitation method, adding 38.46g Mg(NO 3 ) 2 ·6H 2 O, 1.94g Zr(NO 3 ) 4 ·5H 2 O and 28.13gAl(NO 3 ) 3 9H 2 O to 100g of deionized water, fully stirred to dissolve. Add 250 mL of Na to a 500 mL three-neck flask 2 CO 3 solution, the magnesium-zirconium-aluminum mixed solution was added dropwise thereto, and at the same time, the pH value was adjusted to 10.0 with NaOH solution. After the dropwise addition, put the white turbid liquid into a crystallization kettle for crystallization for 18 hours, then wash and filter, and dry the white solid at 100°C to obtain magnesium-zirconium-aluminum hydrotalcite Mg 2 / Zr 0.06 / Al 1 -LDH.

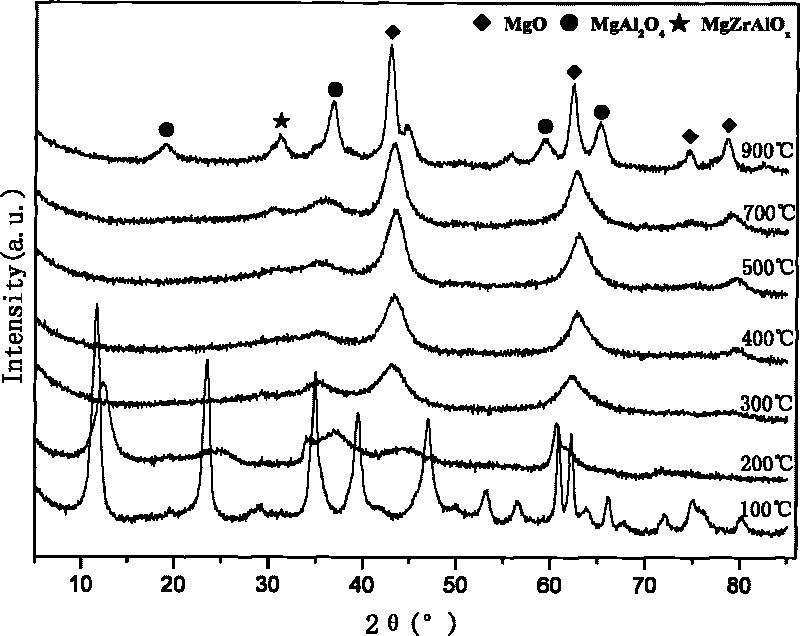

[0027] The above-mentioned magnesium-zirconium-aluminum hydrotalcite (Mg 2 / Zr 0.06 / Al 1 -LDH) was calcine...

Embodiment 2

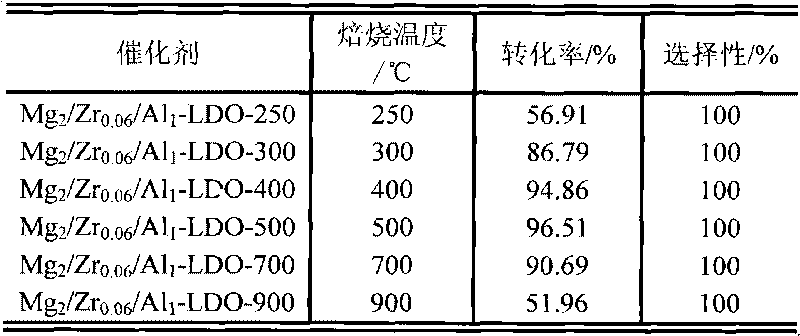

[0028] Embodiment 2: the preparation of the Mg / Zr / Al-LDO catalyst of different calcining temperature

[0029] According to the method of Example 1, the catalyst precursor magnesium-zirconium-aluminum hydrotalcite Mg / Zr / Al-LDH was obtained, and different calcination temperatures (250°C, 300°C, 400°C, 700°C) were obtained by changing the calcination temperature of the catalyst precursor. , 900°C) Mg / Zr / Al-LDO catalyst, the calcination time is 8h. Gained catalyst is recorded as: Mg 2 / Zr 0.06 / Al 1 -LDO-300, Mg 2 / Zr 0.06 / Al 1 -LDO-400, Mg 2 / Zr 0.06 / Al 1 -LDO-700, Mg 2 / Zr 0.06 / Al 1 -LDO-900.

Embodiment 3

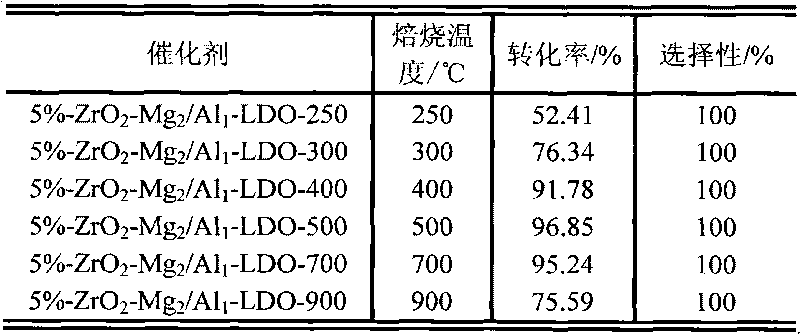

[0030] Embodiment 3: supported zirconium oxide (ZrO 2 - Preparation of Mg / Al-LDO) catalyst

[0031] The preparation of carrier magnesium-aluminum composite oxide (Mg / Al-LDO): by co-precipitation method, adding 38.46g Mg(NO 3 ) 2 ·6H 2 O and 28.13g Al(NO 3 ) 3 9H 2 O to 100g of deionized water, fully stirred to dissolve. Add 250 mL of Na to a 500 mL three-neck flask 2 CO 3 solution, the magnesium-aluminum mixed solution was added dropwise therein, and at the same time, the pH value was adjusted to 10.0 with NaOH solution. After the dropwise addition, the white turbid liquid was put into a crystallization tank for crystallization for 12 hours, washed and filtered, and the white solid was dried at 100°C to obtain magnesium aluminum hydrotalcite (Mg 2 / Al 1 -LDH). The magnesium aluminum hydrotalcite (Mg 2 / Al 1 -LDH), the magnesium-aluminum composite metal oxide (Mg 2 / Al 1 -LDO).

[0032] Then add 1.47g Zr(NO 3 ) 4 ·5H 2 O was dissolved in 100 g of deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com