Temperature-sensitive platinum catalyst and preparation method thereof

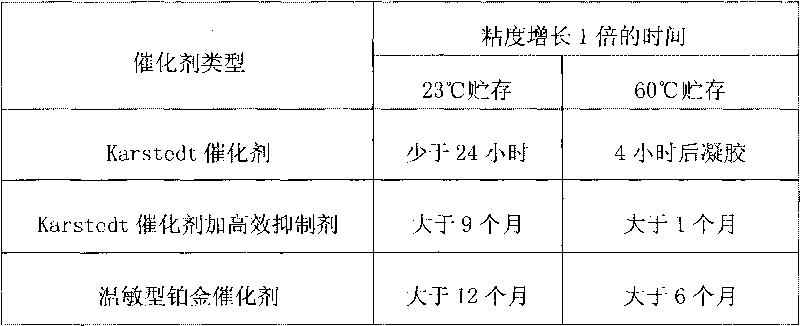

A platinum catalyst, temperature-sensitive technology, used in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Short life and other problems, to achieve the effect of long storage stability, excellent storage stability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] First, 10g of nano-titanium oxide with an average particle diameter of 40nm (its specific surface area is 100m 2 / g) is dispersed in 100g of ethanol under stirring, then 10g of platinum complexes with a platinum content of 5% are added, stirred at 60-70°C for 2h, lowered to room temperature and continued to stir for 24h, after the stirring is completed, at 60-70°C ℃ and vacuum, and then heat-treated at 150℃ for 12 hours to obtain a platinum catalyst carrier; disperse 10g of platinum catalyst carrier into 500g of pure water under stirring, and then add 90g of For polymethylphenylsiloxane, heat up to 90-100°C. After the polymethylphenylsiloxane is completely melted, continue to keep warm and stir for 30 minutes, and then cool to room temperature under stirring. At this time, the temperature-sensitive resin is released from the solution Precipitated, wrapped on the surface of the platinum catalyst carrier, separated by a centrifuge, washed the temperature-sensitive platinu...

example 2

[0028] Prepare the platinum catalyst carrier according to Example 1. The temperature-sensitive resin is precipitated from the solution. After washing with warm water and centrifuging with a centrifuge, add 2000g of methylphenylvinyl silicone oil, and then evacuate under vacuum at 50°C for 4.5h to obtain the Temperature-sensitive platinum catalyst colloid wrapped in epoxy resin with a platinum content of about 200ppm.

example 3

[0030] First, 5g of nano-silicon oxide with an average particle diameter of 10nm (its specific surface area is 400m 2 / g) is dispersed in 100g of acetone under stirring, then add 5g of platinum complex with a platinum content of 5%, stir at 50-60°C for 4h, drop to room temperature and continue stirring for 24h, after the stirring is completed, at 50-70 ℃ and under vacuum to remove the solvent, heat treatment at 120 ℃ for 12h after removing the solvent, to obtain a platinum catalyst carrier;

[0031] Disperse 5g of platinum catalyst carrier into 500g of pure water under stirring, then add 90g of polyacrylamide resin with a softening point of 80-90°C, raise the temperature to 90-100°C, and continue to keep warm and stir after the polyacrylamide resin is completely melted 30min, and then rapidly cooled to room temperature under stirring, at this time, the temperature-sensitive resin was precipitated from the solution, wrapped on the surface of the platinum catalyst carrier, separ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com