Method for preparing synthesis gas from coke oven gas

A technology for coke oven gas and synthesis gas, which is applied in chemical instruments and methods, bulk chemical production, inorganic chemistry, etc., can solve the problem of unsuitable methanol production and F-T synthesis, increase equipment investment and operating costs, and syngas H/C Advanced problems, to achieve the effect of less impurities, comprehensive utilization, and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

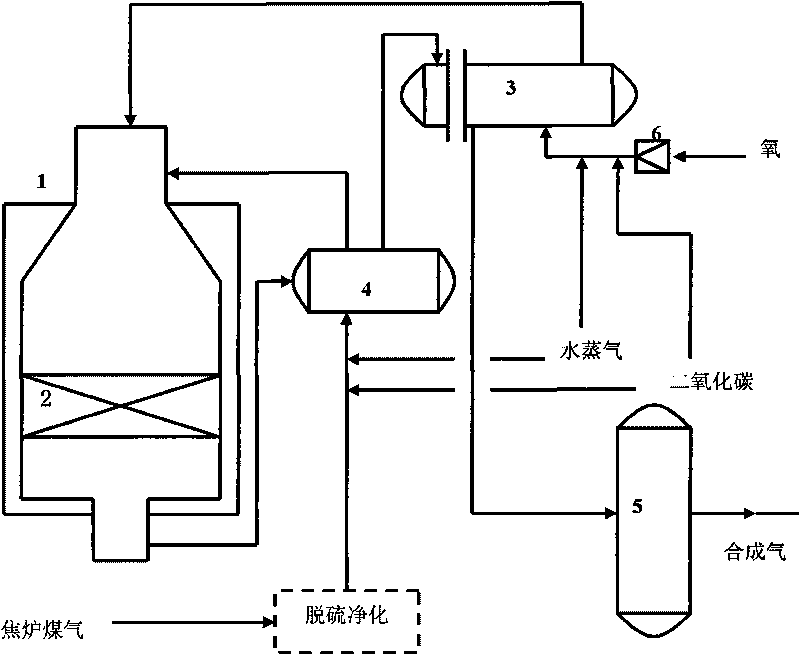

[0026] Firstly, the coke oven gas produced by high-temperature dry distillation of coal as raw material gas is desulfurized and purified, and the sulfur content after treatment is less than 5ppm.

[0027] Secondly, at normal temperature and under a pressure of 1-4MPa, mix some carbon dioxide and water vapor with a purity of 93% and coke oven gas after desulfurization and purification, and send it to the waste heat boiler 4 to preheat to 400-700°C; at the same time, the Some carbon dioxide and water vapor with a purity of 93% and oxygen with a purity of 92% are mixed and sent to the preheater 3 to be preheated to 400-700°C.

[0028] The amounts of oxygen, carbon dioxide and water vapor used per mole of desulfurized and purified coke oven gas are: oxygen ≤ 0.28 mol; carbon dioxide ≤ 0.3 mol; water vapor ≤ 0.3 mol.

[0029] Then, the preheated raw gas is heated at 2500~5000h -1 Under the condition of space velocity, they are fed into the reactor 1 and reacted while mixing. At 10...

Embodiment 2

[0046] Firstly, the coke oven gas produced by high-temperature dry distillation of coal as raw material gas is desulfurized and purified, and the sulfur content after treatment is less than 5ppm.

[0047] Secondly, at normal temperature and under a pressure of 1-4MPa, mix some carbon dioxide and water vapor with a purity of 99% and coke oven gas after desulfurization and purification, and send it to the waste heat boiler 4 to preheat to 400-700°C; at the same time, the Part of the carbon dioxide and water vapor with a purity of 99% and oxygen with a purity of 98% are mixed and sent to the preheater 3 to be preheated to 400-700°C.

[0048] The amounts of oxygen, carbon dioxide and water vapor used per mole of desulfurized and purified coke oven gas are: oxygen ≤ 0.28 mol; carbon dioxide ≤ 0.3 mol; water vapor ≤ 0.3 mol.

[0049] Then, the preheated raw gas is heated at 2500~5000h -1 Under the condition of space velocity, they are fed into the reactor 1 and reacted while mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com