Ti3AlC2/Al2O3 compound material and preparation method thereof

A composite material and composite powder technology, applied in the field of material science, can solve the problems of inability to carry out large-scale industrial production, influence of material performance, high synthesis temperature, etc., and achieve the effect of low cost, uniform and dense structure, and low firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of Ti 3 AlC 2 / Al 2 o 3 Composite material, its raw material weight composition is: 250 purpose Ti powder accounts for 66.25% of total weight, 200 purpose Al powder accounts for 15.91%, 1200 purpose C powder accounts for 11.70% and 325 purpose TiO 2 Accounted for 6.14%.

[0020] The preparation method of the present embodiment comprises the following steps:

[0021] 1. 66.25% of the total weight of 325 mesh Ti powder, 15.91% of 200 mesh Al powder, 11.70% of 1200 mesh C powder, 6.14% of 325 mesh TiO 2 mix well;

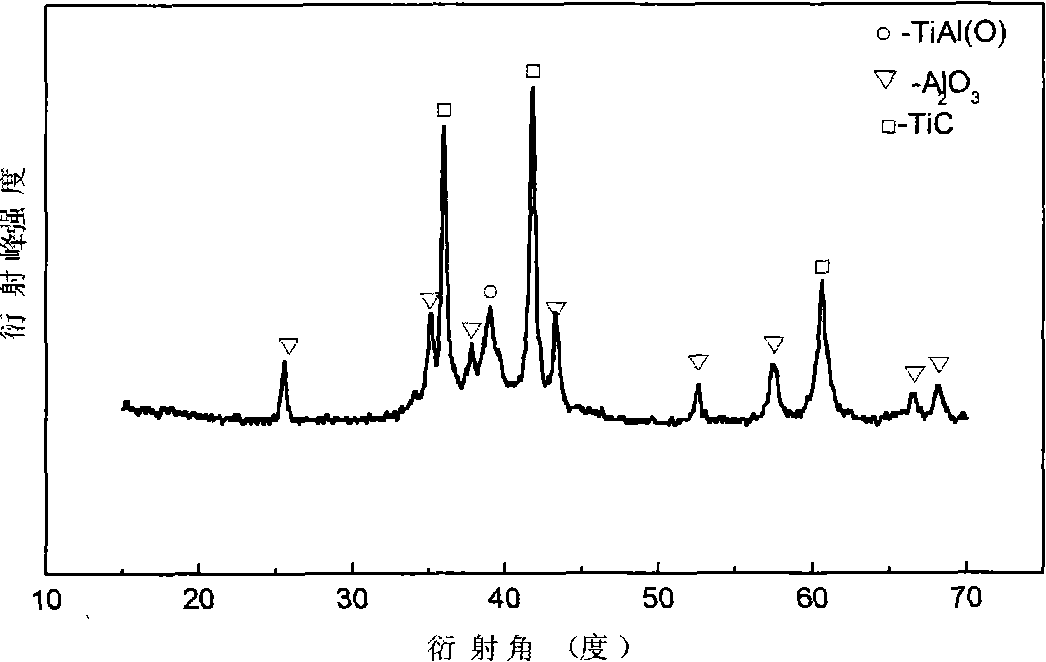

[0022] Two, add the sodium stearate dispersant of mixture quality 1.0% in the mixture, adopt high-energy ball mill, the rotating speed of planetary ball mill is 750 revs per minute, and material ball mass ratio is 1: 10, ball mills 20 hours, forms main crystal phase TiC, Al 2 o 3 and TiAlO fine composite powder;

[0023] 3. Dry the composite powder ball-milled in step 2 in vacuum at 75°C for 5 hours;

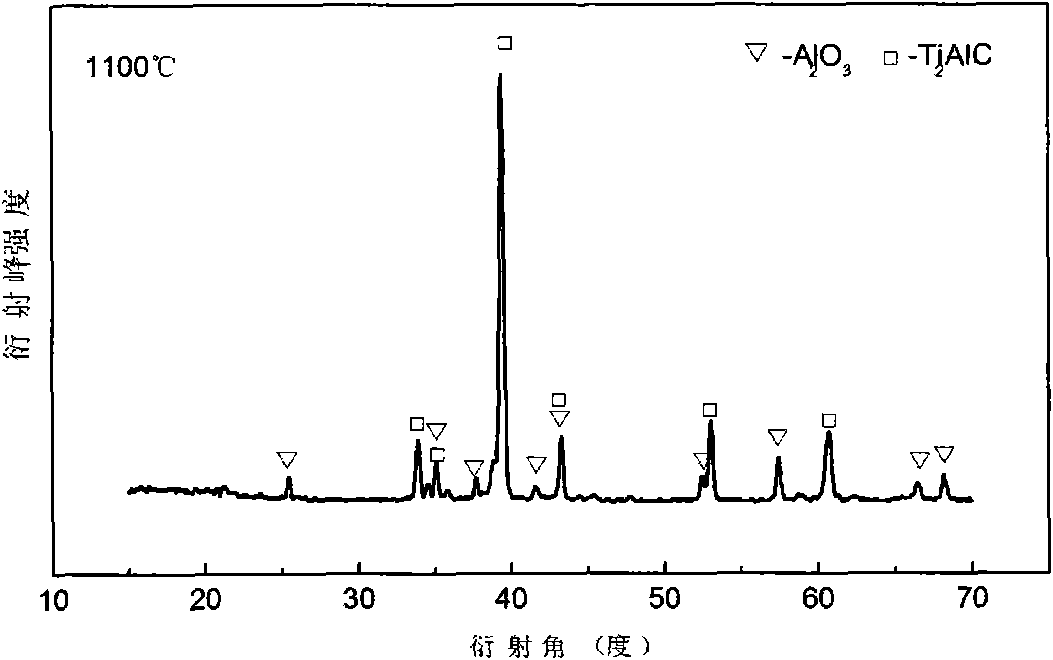

[0024] 4. Put the dried powder into a graph...

Embodiment 2

[0027] A kind of Ti 3 AlC 2 / Al 2 o 3 Composite material, its raw material weight composition is: 270 mesh Ti powder accounts for 70.89% of total weight, 170 mesh Al powder accounts for 14.65%, 1200 mesh C powder accounts for 12.09% and 460 mesh TiO 2 Accounted for 2.37%.

[0028] The preparation method of the present embodiment comprises the following steps:

[0029] 1. 70.89% of the total weight of 270-mesh Ti powder, 14.65% of 170-mesh Al powder, 12.09% of 1200-mesh C powder, 2.37% of 460-mesh TiO 2 mix well;

[0030] Two, add the sodium stearate dispersant of mixture quality 1.0% in the mixture, adopt high-energy ball mill, the rotating speed of planetary ball mill is 800 revs per minute, and material ball mass ratio is 1: 10, ball mills 24 hours, forms main crystal phase TiC, Al 2 o 3 and TiAlO composite powder;

[0031] 3. Dry the composite powder ball-milled in step 2 in vacuum at 80°C for 4 hours;

[0032]4) Put the dried powder into a graphite grinding tool,...

Embodiment 3

[0035] A kind of Ti 3 AlC 2 / Al 2 o 3 Composite material, its raw material weight composition is: 325 mesh Ti powder accounts for 58.75% of total weight, 100 mesh Al powder accounts for 17.94%, 1200 mesh C powder accounts for 11.06% and 325 mesh TiO 2 12.25%.

[0036] The preparation method of the present embodiment comprises the following steps:

[0037] 1. The 325-mesh Ti powder, 17.94% of the 100-mesh Al powder, 11.06% of the 1200-mesh C powder and 12.25% of the 325-mesh TiO 2 mix well;

[0038] Two, add the sodium stearate dispersant of mixture quality 0.6% in the mixture, adopt high-energy ball mill, the rotating speed of planetary ball mill is 780 revs per minute, and material ball mass ratio is 1: 10, and ball mills 18 hours, forms main crystal phase TiC, Al 2 o 3 and TiAlO composite powder;

[0039] 3. Dry the composite powder ball-milled in step 2 in vacuum at 80°C for 4 hours;

[0040] 4. Put the dried powder into a graphite grinding tool, and sinter it und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com