Method for preparing and condensing polyaromatic hydrocarbon resin by using bamboo tar

A polycyclic aromatic hydrocarbon resin and bamboo tar technology, applied in the field of preparation of condensed polycyclic aromatic hydrocarbon resin, can solve the problems of high cost, limited production and application, non-renewable, etc., and achieve high adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] COPNA resin was synthesized by bamboo tar-tere-phenylenedimethanol system.

[0023] (1) taking by weighing bamboo tar and tere-xylylenedimethanol that mass ratio is 1: 1 is put into the flask, adding the p-toluenesulfonic acid that accounts for bamboo tar and tere-xylylenedimethanol quality 9% is catalyst, feeds N 2 , control the reaction temperature at 160°C, and take it out after 11 hours of reaction. The product in the flask is a black viscous liquid at the reaction temperature, and filaments can be pulled out when cooled, and it is a black brittle solid at room temperature.

[0024] The reaction took 11 hours, and the yield was 83.93% obtained from (the mass of the substance in the flask after the reaction) ÷ (the mass of the substance in the flask before the reaction).

[0025] The softening point and β-resin content of the obtained product were measured. The softening point test adopts the needle injection method. After crushing 3-4g resin, put it into the softe...

Embodiment 2

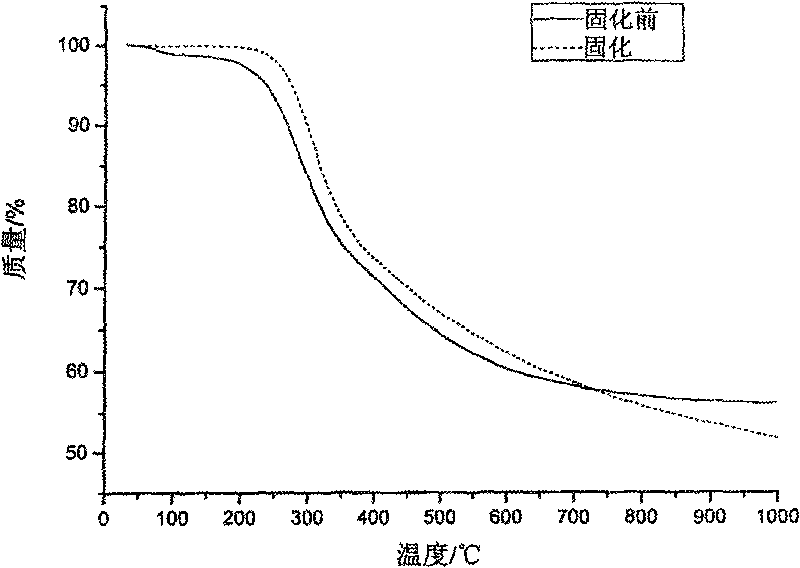

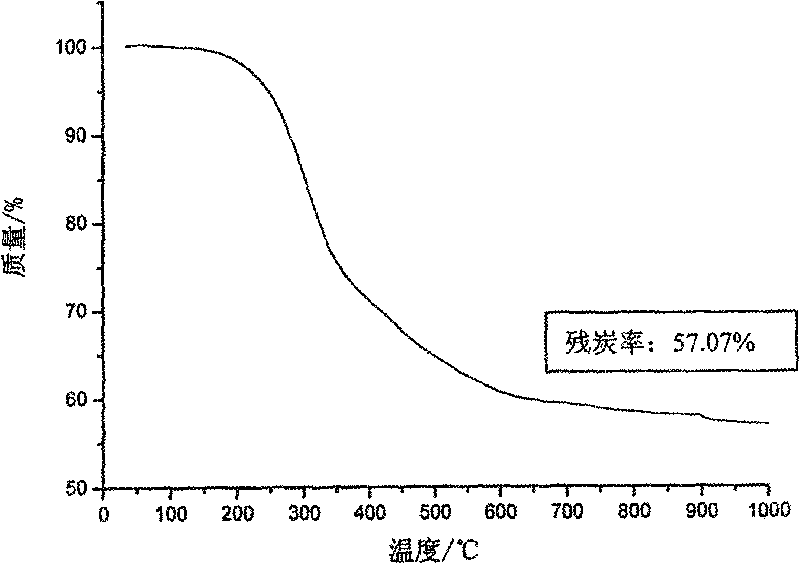

[0028] The method of operation is the same as in Example 1, except that the amount of p-toluenesulfonic acid used is 7% of the quality of bamboo tar and terephthalamide, the reaction temperature is 140°C, and the reaction time is taken out after 9h25min, and the product becomes Black brittle solid. The softening point and β-resin content of the synthetic product were tested, and the measured softening point was 78°C, which indicated that the resin was easy to process; the β-resin content was 92%, and the resulting product had high cohesiveness. figure 2 The TG-DSC test shows that the initial pyrolysis temperature of the synthesized product can reach 235 °C.

[0029] The curing conditions are N2 protection, heat preservation at 120°C for 20 hours in a blast oven, and heat preservation at 200°C for 2 hours to obtain an insoluble and infusible high-temperature-resistant resin.

Embodiment 3

[0031] The operating method is the same as in Example 1, except that the concentrated sulfuric acid (mass concentration is 98%) is used as a catalyzer, which is added dropwise to the reaction system. The mass ratio of sulfuric acid is 5%, and the reaction temperature is 140°C. Two cases were violent, the reaction time was shortened to 2h, and the softening point of the product was measured to be 84°C. The curing step is the same as in Example 1 to obtain an insoluble and infusible high temperature resistant resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com